Construction process for gas producing system in oil well layer

A construction process and system technology, applied in other gas emission reduction technologies, production fluids, wellbore/well components, etc., can solve problems such as storage safety, transportation, environmental problems, lack of gas sources in oil and gas fields, and unstable effects. Significant oil increase effect, improved oil-water mobility ratio, simple construction effect

Inactive Publication Date: 2015-09-16

CHINA PETROLEUM & CHEM CORP +1

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented technology uses an anti-sticking agent called Gas Channeling Preventer (GCP) to help keep water flowing smoothly between layers without causing damage or blocking up other materials like hydrocarbons during production operations. It also improves oil recovery efficiency while maintaining good quality products for sale at retailers' shops. Additionally it provides safer ways to use gases such as methane instead of air when producing liquid fuel due its lower risk compared to traditional methods. Overall this method allows efficient and effective extraction of petroleum resources worldwide

Problems solved by technology

This patented describes methods that use carbon dioxide (CO2) or another substances called hydrogen sulfate (H2/SO1.33>) to improve recoveries of petroleum reservoir fluids such as bitumen production. These techniques are effective but require expensive infrastructure and may result in harmful emissions during drilling operations due to their potential negative effects on environment quality. Additionally, these processes involve high energy consumption and storage concerns associated with them.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

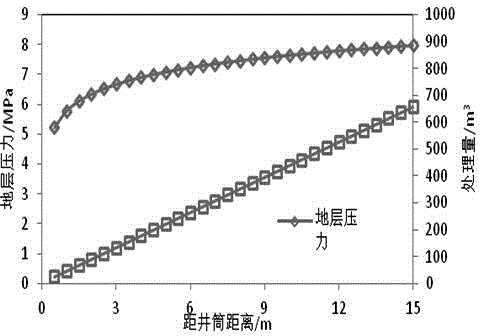

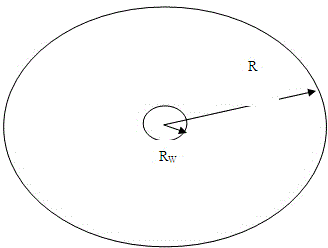

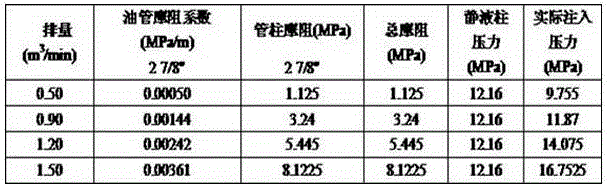

The invention provides a construction process for a gas producing system in an oil well layer, and relates to the technical field of oil well single-well production increase. The construction process comprises the following steps that: firstly, anti-gas channeling agents are used for sealing and blocking the high-permeability formation; the construction effect reduction due to the onrush of gas producing agents injected in the later period can be prevented; two kinds of gas producing agents capable of producing CO2 through reaction are used and are sequentially injected into the formation, so that a great amount of generated CO2 is mixed with crude oil in the formation; the formation energy is increased; the organic blockage and the inorganic blockage of a near-well zone are relieved; the oil-water fluidity ratio is improved; and the permeability of the near-well zone is improved, so that the goal of improving the single-well productivity is achieved. The construction process can better solve the problems of corrosion and scale formation on oil well equipment, pollution on a gas source, storage and transportation and environment and the like during the CO2 throughput process can be well solved; and the advantages of simple construction, low cost, safety, environment protection and the like are realized.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner CHINA PETROLEUM & CHEM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap