Microscope base milling fixture

A fixture and mirror base technology, which is applied in the field of mechanical processing, can solve the problems of low production efficiency and achieve the effects of high production efficiency, simple clamping, and accurate clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

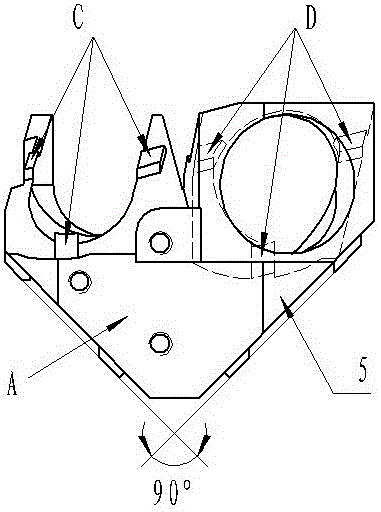

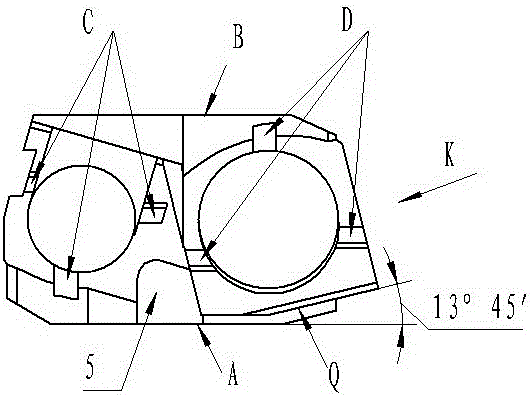

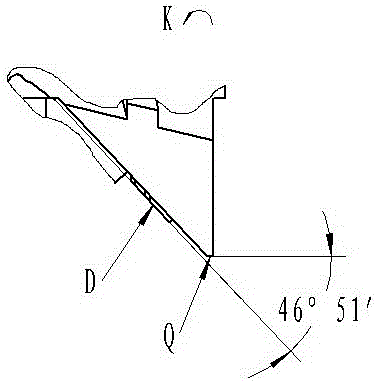

[0026] Such as Figure 7 , Figure 8 , Figure 9 The shown mirror base milling fixture includes a base 1, the base 1 is provided with a positioning slant block 1-2 and two mounting base plates 1-1 respectively connecting the two ends of the positioning slanting block 1-2, and the mounting base plate 1-1 There is a mounting groove on the top, and the positioning inclined block 1-2 has a positioning surface that forms an angle γ with its bottom surface, and the angle γ is 46°33′, such as Figure 10 , Figure 11 , Figure 12 As shown; two V-shaped supporting blocks 2 symmetrically arranged are installed on the positioning surface by bolts, and the angle between the V-shaped working surfaces of the V-shaped supporting blocks 2 is 90 degrees, as Figure 13 Shown; The V-shaped openings of the two V-shaped supporting blocks 2 are facing the high side of the positioning inclined block 1-2 and are inclined to the two outer ends respectively, the angle between the V-shaped working surf

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 lies in that the included angle γ is 46°35′, and the included angle θ is 26°21′. All the other technical features are the same as in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap