A large load-bearing compression shape memory polymer composite release mechanism for space

A technology of memory polymer and release mechanism, which is applied to the docking device of aerospace vehicles, etc., can solve the problems of easy damage and impact of explosive fragments, and achieve the effects of simple and reliable structure, weight reduction, and stable release process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

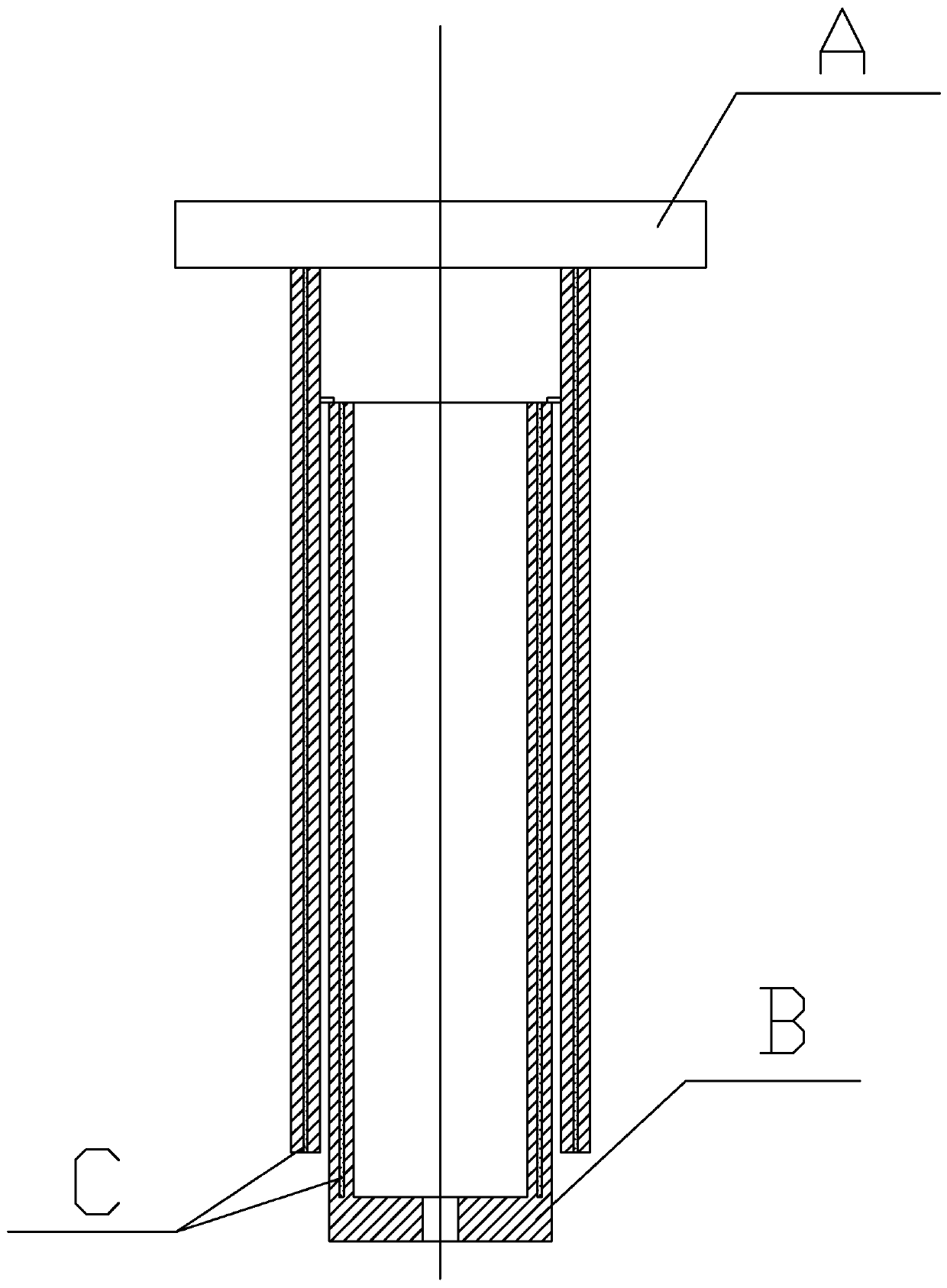

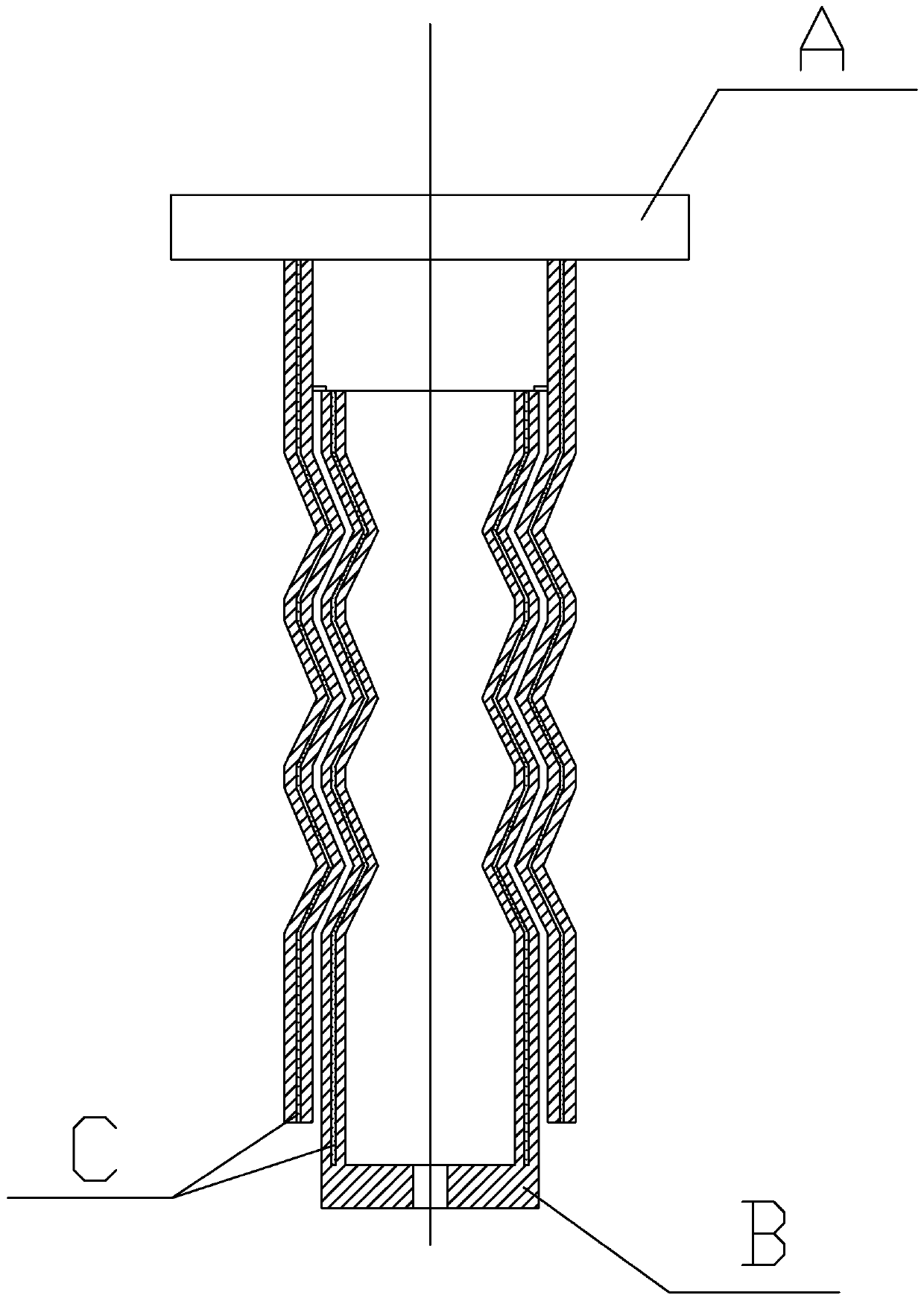

[0028] Specific implementation mode one: combine figure 1 — Figure 10 Describe this embodiment, a large load-bearing compressed shape memory polymer composite material release mechanism for space, including a main structure connector A, a release mechanism connector B and a heating drive device C; the main structure connector A and the release mechanism The material of the mechanism connector B is a shape memory polymer composite material;

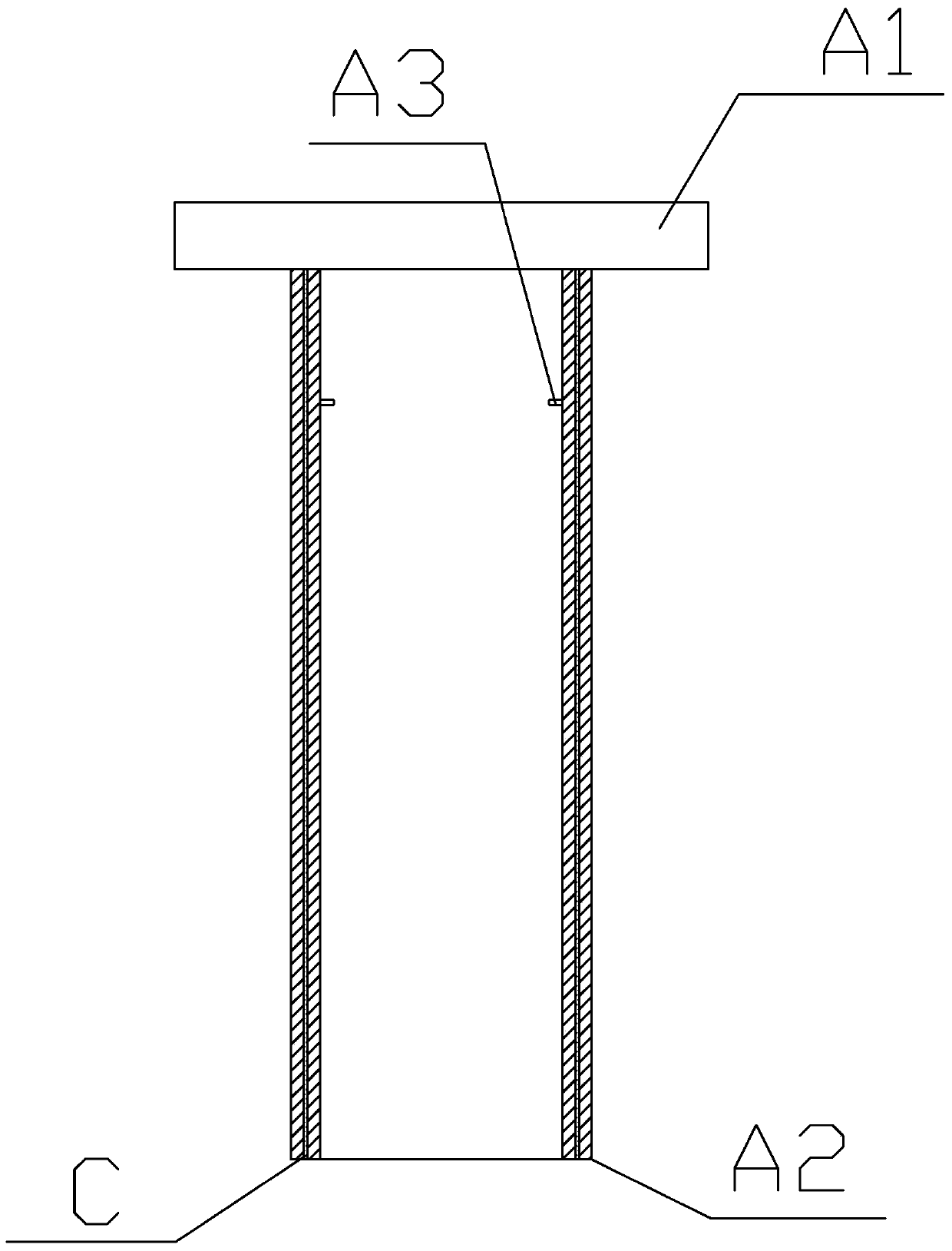

[0029] The main structure connector A includes a flanged connection plate A1 and a release mechanism outer sleeve A2; the flanged connection plate A1 is located at the upper end of the release mechanism outer sleeve A2;

[0030] The release mechanism connector B includes a connection chassis B1 and a release mechanism inner sleeve B2, and the connection chassis B1 is located at the lower end of the release mechanism inner sleeve B2;

[0031] The heating drive device C is provided as one set or two sets,

[0032] like Figure 7 — Figure

specific Embodiment approach 2

[0038] Specific embodiment two: The main structure connector A described in this embodiment is also provided with a stop pin A3; the stop pin A3 is arranged on the sleeve inner wall of the outer sleeve A2 of the release mechanism; the outer sleeve A2 of the release mechanism is sleeved in the release mechanism When the outer side of the sleeve B2, the stop pin A3 blocks the inner sleeve B2 of the release mechanism, and the connecting chassis B1 is exposed under the outer sleeve A2 of the release mechanism.

[0039] Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: The shape memory polymer composite material described in this embodiment is a styrene-based shape-memory polymer, an epoxy-based shape-memory polymer, a cyanate-based shape-memory polymer, a shape-memory polyester, a shape-memory Styrene-butadiene polymer or shape memory polynorbornene.

[0041] Other steps and parameters are the same as in the second embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap