Foam separator for wastewater treatment

A foam separation and wastewater treatment technology, applied in the field of foam separators, can solve the problems of low separation efficiency, high cost, and poor separation effect, and achieve good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention will be defined more clearly.

[0025] The advantages of the foam separator for wastewater treatment of the present invention are: with a tangentially arranged water inlet pipe and an inclinedly arranged bottom plate, the separation effect is good, the wastewater can be discharged from the tank in time, and the sundries in the wastewater are not easy to be deposited in the tank internal.

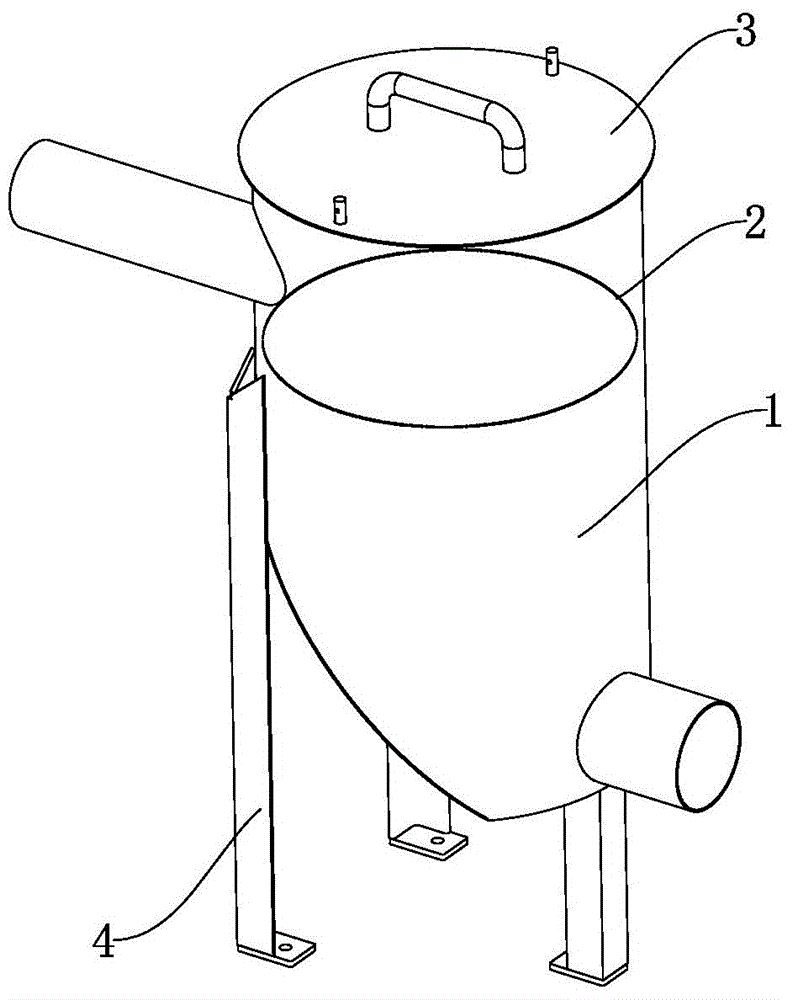

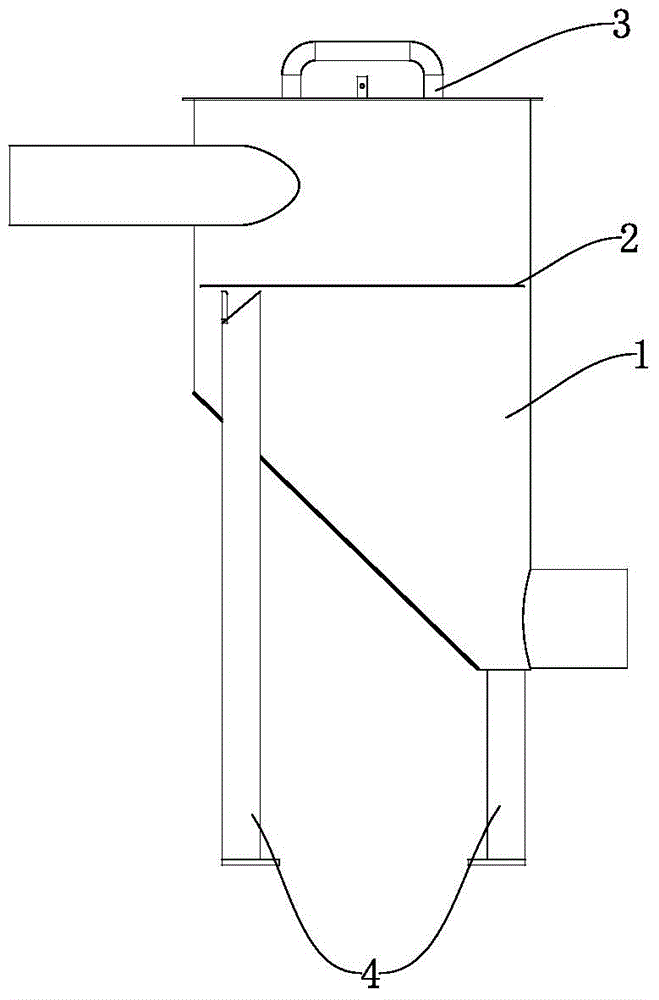

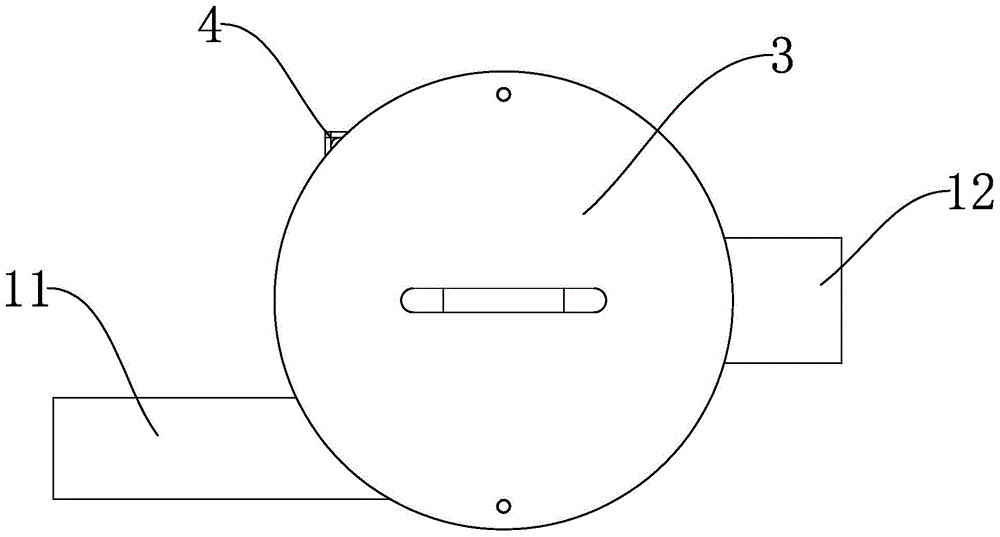

[0026] Such as figure 1 , figure 2 , image 3 As shown, a foam separator for waste water treatment includes a tank body 1 which is a vertically arranged cylindrical structure with an inlet pipe 11 at its upper end and an outlet pipe 12 at its lower end. The foam separator for waste water treatme

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap