Beewax separating device

A separation device and technology of beeswax, applied in the direction of separation methods, precipitation separation, chemical instruments and methods, etc., can solve the problems affecting the separation efficiency and effect of beeswax, low production efficiency, etc., and achieve high separation efficiency and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The present invention will be further described below with reference to the drawings and embodiments.

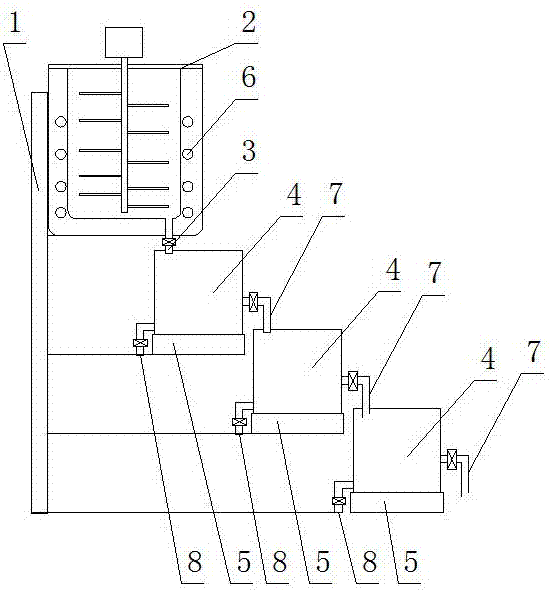

[0012] Such as figure 1 As shown, a beeswax separation device includes a frame 1, on which a heating stirring device 2 is installed, the stirring device has a wax outlet 3, and a beeswax separation tank 4 is installed under the wax outlet; its feature is : A vibrating device 5 is installed below the beeswax separation tank. 6 in the figure is a heating tube, which can heat the stirring device. The invention can realize the rapid layering of beeswax under the action of the vibrating device and realize the invention the goal of.

[0013] Furthermore, there are multiple beeswax separation tanks. Each beeswax separation tank has a middle wax melting outlet 7 and a bottom melting wax outlet 8. The middle wax melting outlet of the previous beeswax separation tank leads to the next beeswax At the entrance of the separation tank, there are multiple vibration devices, and a vibratio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap