Macromolecular coated scale inhibitor for oil field and preparation method thereof

A polymer and antiscalant technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problem of low thermal stability of antiscalants, loss of antiscaling effect, To solve problems such as poor scale inhibition effect, achieve good sustained release effect, prolong the protection period, and achieve the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

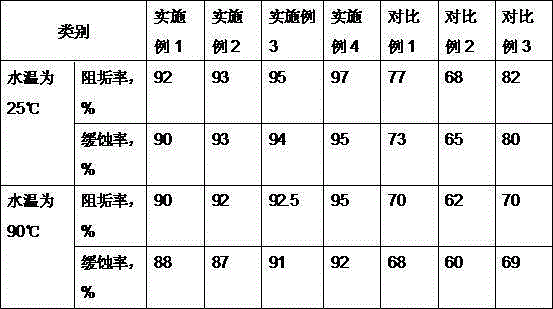

Examples

Example Embodiment

[0037] Example 1

[0038] A method for preparing a polymer film-coated scale inhibitor for oilfields includes the following steps:

[0039] Step (1), according to parts by weight, weigh out 0.02 parts of Polyporus umbellatus extract, 0.1 part of artemisinin, 13 parts of citric acid, 5 parts of sorbitol, 2 parts of 2-(diethanolamino)ethanesulfonic acid, 0.5 part of sulfosuccinate, 0.1 part of dehydroabietic acid, 10 parts of ethanol, 68 parts of water;

[0040] In step (2), the polyporus umbellatus extract, artemisinin and sulfosuccinate weighed in step (1) are added to ethanol and mixed uniformly to obtain mixed liquid A;

[0041] Step (3), add the citric acid, sorbitol, 2-(diethanolamino)ethanesulfonic acid and dehydroabietic acid weighed in step (1) to the water, and then heat to 40°C, then add step (2) ) The obtained mixture A is stirred at a speed of 50r / min until the mixture is uniform, and the mixture B is obtained;

[0042] Step (4), soak the porous chitosan microspheres in the

Example Embodiment

[0046] Example 2

[0047] A method for preparing a polymer film-coated scale inhibitor for oilfields includes the following steps:

[0048] Step (1), in terms of parts by weight, weigh out 0.04 parts of Polyporus umbellatus extract, 0.2 parts of artemisinin, 18 parts of citric acid, 10 parts of sorbitol, 5 parts of 2-(diethanolamino)ethanesulfonic acid, 0.8 parts of sulfosuccinate, 0.3 parts of dehydroabietic acid, 15 parts of ethanol, 83 parts of water;

[0049] In step (2), the polyporus umbellatus extract, artemisinin and sulfosuccinate weighed in step (1) are added to ethanol and mixed uniformly to obtain mixed liquid A;

[0050] In step (3), the citric acid, sorbitol, 2-(diethanolamino)ethanesulfonic acid and dehydroabietic acid weighed in step (1) are added to water, and then heated to 45°C, then added to step (2) 1) The obtained mixture A is stirred at a speed of 80r / min until the mixture is uniform, and the mixture B is obtained;

[0051] Step (4), soak the porous chitosan micr

Example Embodiment

[0055] Example 3

[0056] A method for preparing a polymer film-coated scale inhibitor for oilfields includes the following steps:

[0057] Step (1), weigh out 0.034 parts of Polyporus umbellatus extract, 0.14 parts of artemisinin, 15 parts of citric acid, 6 parts of sorbitol, 4 parts of 2-(diethanolamino)ethanesulfonic acid, 0.7 parts of sulfosuccinate, 0.22 parts of dehydroabietic acid, 13 parts of ethanol, 77 parts of water;

[0058] In step (2), the polyporus umbellatus extract, artemisinin and sulfosuccinate weighed in step (1) are added to ethanol and mixed uniformly to obtain mixed liquid A;

[0059] Step (3), add the citric acid, sorbitol, 2-(diethanolamino)ethanesulfonic acid and dehydroabietic acid weighed in step (1) to water, and then heat to 42°C, then add step (2) 1) The obtained mixture A is stirred at a speed of 60r / min until the mixture is uniform, and the mixture B is obtained;

[0060] Step (4), soak the porous chitosan microspheres in the mixed solution B, and after

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap