Counter boring device for car hydraulic electric power steering gear shell

A technology of hydraulic power steering and housing, which is applied in the direction of positioning device, clamping, support, etc. It can solve the problems of increased labor intensity of operators, uneven machining allowance of blanks, and affecting the life of machine tool spindles, etc., and achieves convenient and fast replacement of products , Low labor intensity of employees, reduction of equipment input costs and demand for electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

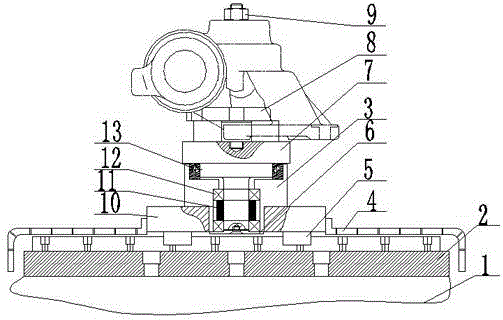

[0010] see figure 1 , an automobile hydraulic power steering gear housing countersinking device, comprising a machine tool table 1, a first clamping body 2, a second clamping body 3, a chain guard 4, a guide rail slider mechanism 5, a locking gasket 6, Rotating mandrel 7, positioning replaceable mandrel 8, pressing nut 9, second clamping body bottom plate 10, spacer 11, first bearing 12 and second plane bearing 13; the bottom end

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap