Cigarette smoldering detection box

A technology for detecting boxes and cigarettes, used in measuring devices, mechanical measuring devices, chemical analysis by combustion, etc., can solve the problems of difficulty in ensuring the consistency and accuracy of measurement, increasing the workload of inspection personnel, and large manual inspection errors. , to achieve the effect of improving measurement accuracy, simple structure, and ensuring the consistency of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings and specific embodiments. It should be noted that in the drawings or descriptions, similar or identical parts use the same figure numbers, and implementations that are not shown or described in the drawings The method is a form known to those of ordinary skill in the art. In addition, the directional terms mentioned in the embodiments, such as "upper", "lower", "top", "bottom", "left", "right", "front", "rear", etc., are only for reference to the accompanying drawings. The directions are not intended to limit the protection scope of the present invention.

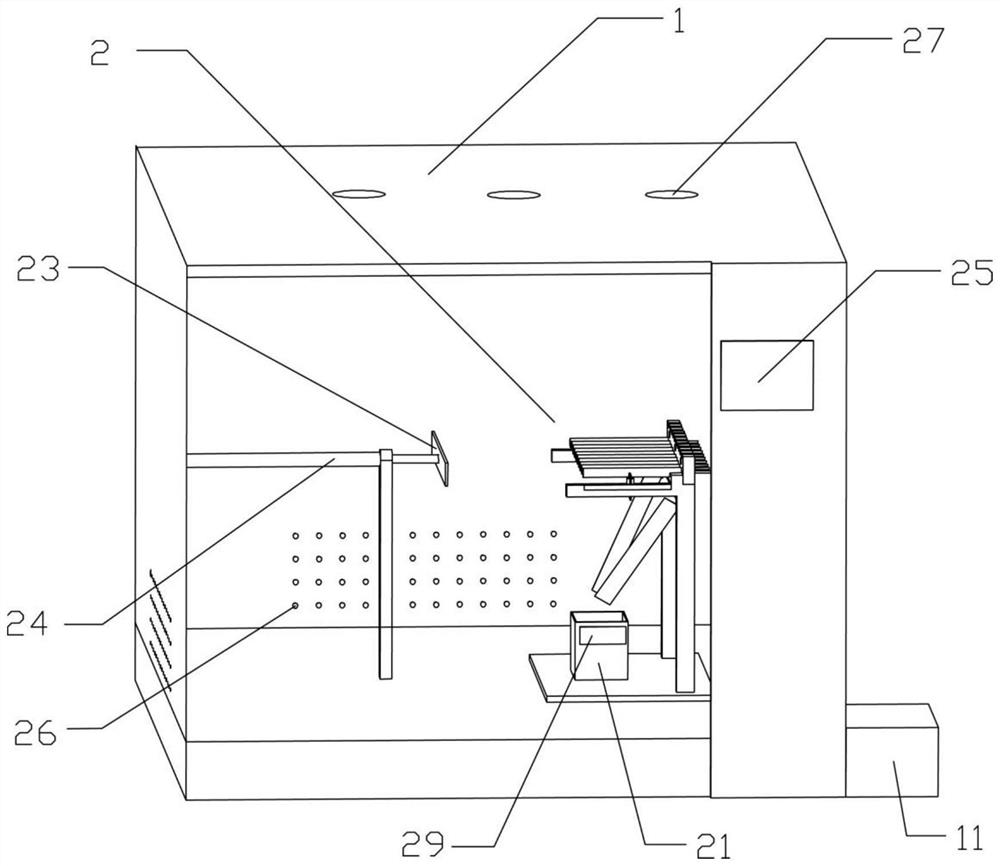

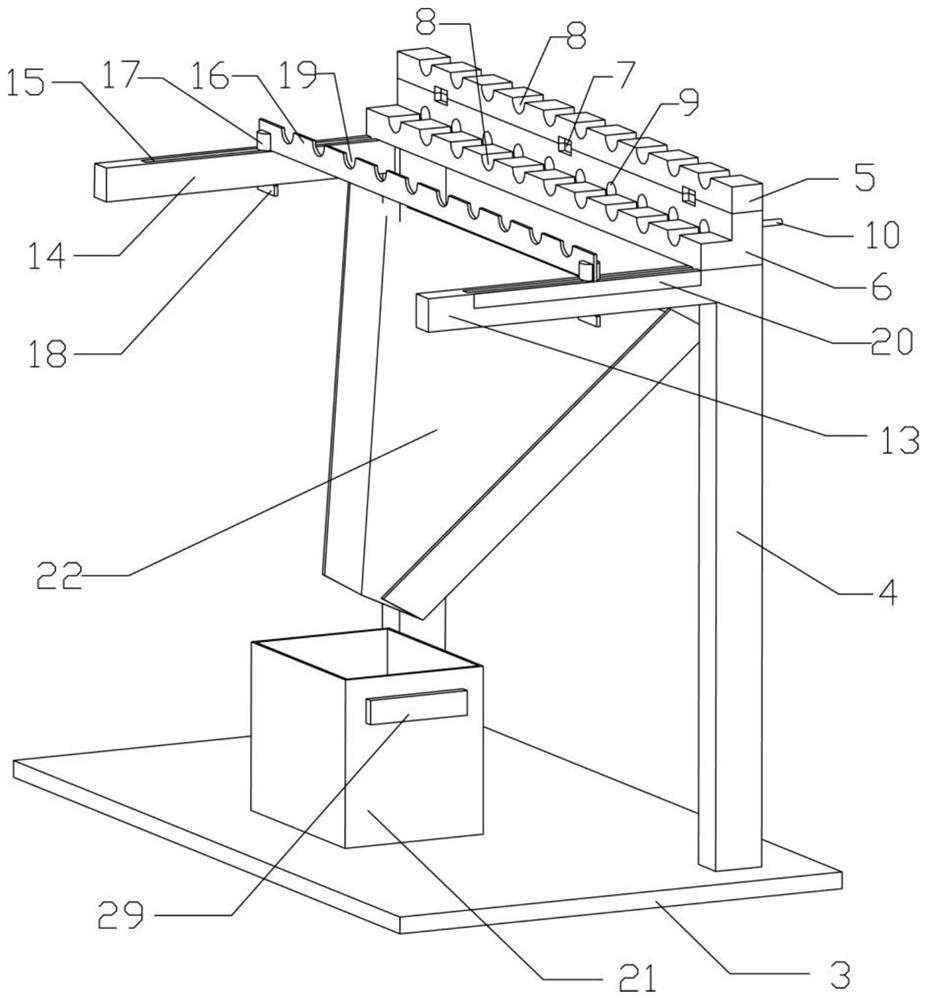

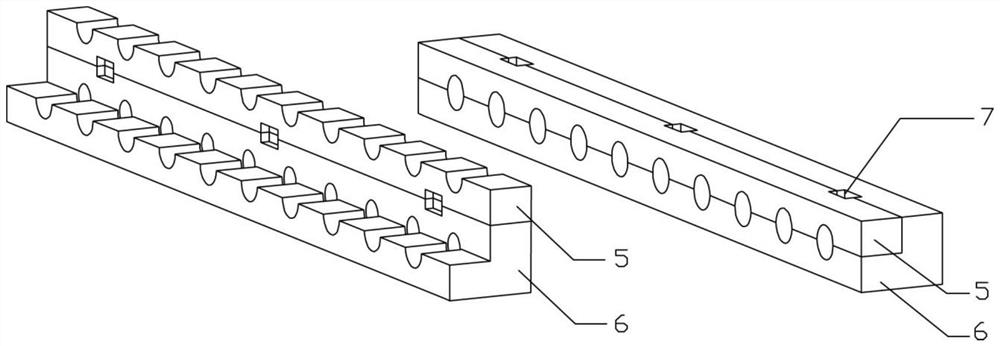

[0026] Such as Figure 1-Figure 5As shown, the present invention provides the following technical solutions: a cigarette smoldering detection box, including a box body 1, a smoldering frame 2 and an electric heating sheet 23 arranged in the box body 1, the smoldering frame 2 includes a bottom plate 3, a fixed The bracket 4 on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap