Annular welding seam detection device with indication control function

A technology for annular welds and detection devices, applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as unreliable improvement, lack of detection devices, and low efficiency, so as to achieve suitable promotion and use, simplify management, and avoid later stages classification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

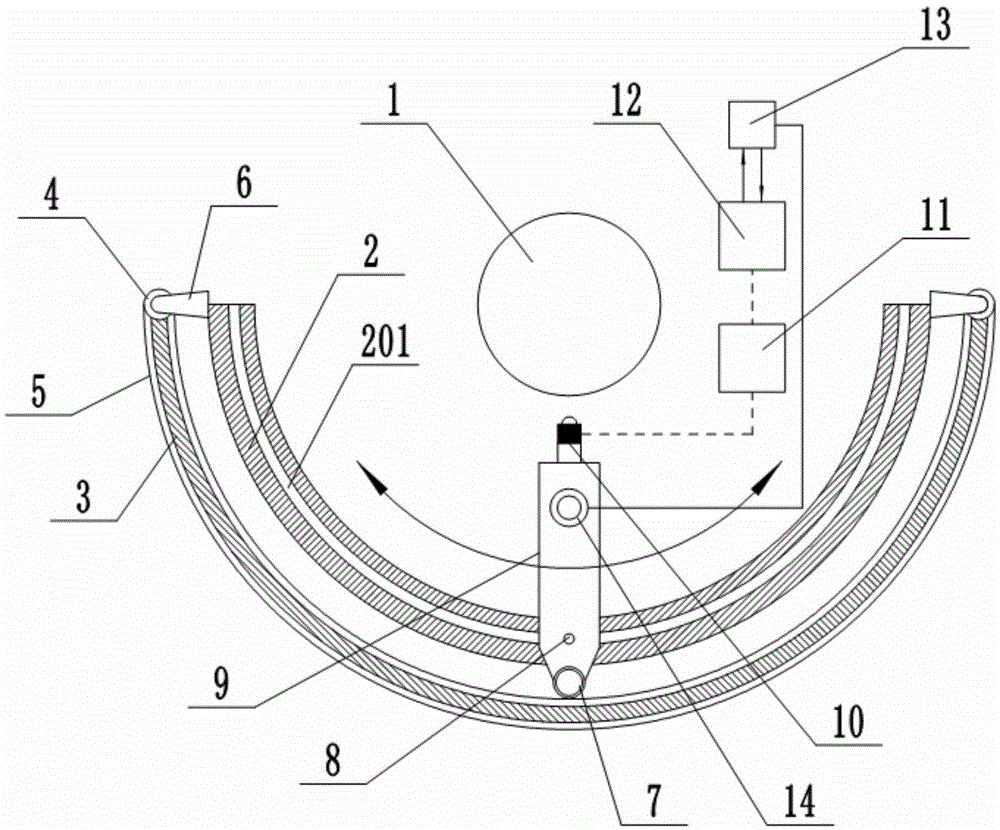

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, in the circular weld detection device with indicator control of this embodiment, the steel ring 1 is placed in an arc-shaped guide device, and a weld detection head 9 is slidably installed in the arc-shaped guide device, and the weld detection head 9 faces the steel ring 1; The arc guide device includes an inner arc guide plate 2 and an outer arc drive plate 3 set inside and outside. The inner arc guide plate 2 is provided with an arc guide groove 201, and both ends of the outer arc drive plate 3 pass through the ends The gear 4 is equipped with a rack 5, and the end gear 4 is connected to the inner arc guide plate 2 through a bracket 6; the outer end of the weld inspection head 9 is equipped with a guide gear 7 and a guide shaft 8, and a guide gear 7 and a rack 5 Engaged, the guide shaft 8 is fitted in the arc-s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap