Engine bearing bush assembling technology

An assembly process and engine shaft technology, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve problems such as low efficiency, many unreliable factors, and manual failure to ensure no mistakes, so as to prevent misoperation and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

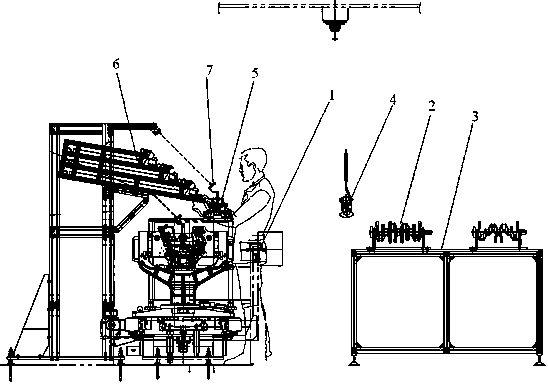

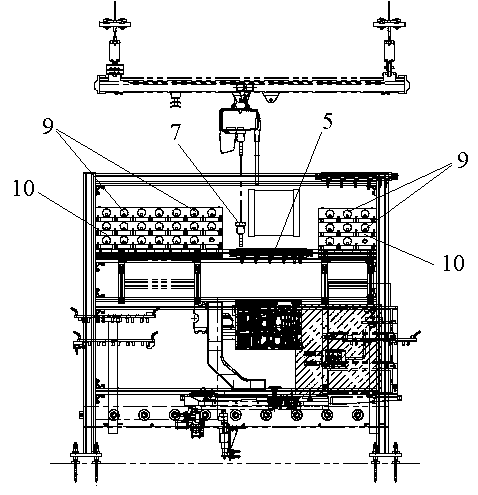

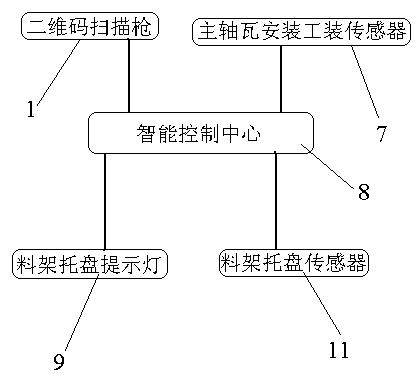

[0018] Example: see figure 1 , figure 2 , image 3 .

[0019] An engine bearing bush assembly process, the process steps are as follows:

[0020] a. Use the QR code scanning gun 1 to scan the QR code pasted on the engine block in advance, and hang the crankshaft 2 from the crankshaft rack to the visual inspection workbench 3;

[0021] b. Check the appearance of the crankshaft 2. After the appearance is qualified, use the QR code scanner 1 to scan the QR code pre-attached to the rear end of the crankshaft 2;

[0022] c. The intelligent control center calculates and compares the cylinder block information sent by the connected two-dimensional code scanning gun 1 with the crankshaft information, obtains the result of tile selection, and starts to light on the intelligent material rack 6 to prompt;

[0023] d. Take the main bearing bush according to the green light of the intelligent material rack 6, and install the main bearing bush in the cylinder block and the main bearing ca

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap