Zinc oxide nano material resistance measurement method and device

A zinc oxide nanometer and resistance measurement technology, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of increasing experimental costs and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

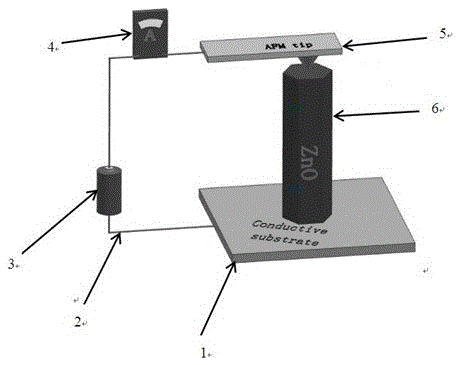

[0012] A method and device for measuring the resistance of zinc oxide nanomaterials, comprising: a conductive substrate 1, the conductive substrate is connected to a wire (1), the wire (1) 2 is connected to a power supply, and the power supply passes through the wire (2) connected to the ammeter 3, the ammeter is connected to the atomic force microscope probe 4 through the wire (3), the atomic force microscope probe is in contact with the zinc oxide nanomaterial 5, and the zinc oxide nanomaterial is in contact with the conductive substrate 6 to form a closed loop.

Embodiment 2

[0014] According to the method and device for measuring resistance of zinc oxide nanomaterials described in Example 1, the probe tip of the atomic force microscope is partially coated with a gold layer.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap