Optimized lightning rod

A technology of lightning rods and auxiliary pins, which is applied in the direction of electrical components, circuits, corona discharge devices, etc., can solve the problems of small protection range, short service life, and weak wind resistance, and achieve long service life, avoid damage, and resist wind. strong wind effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

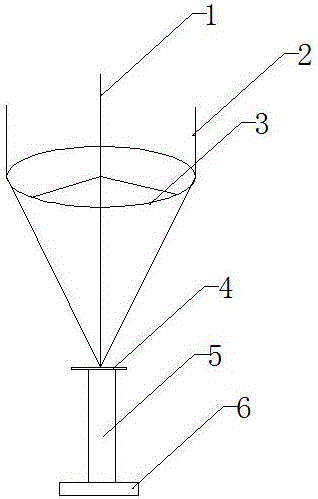

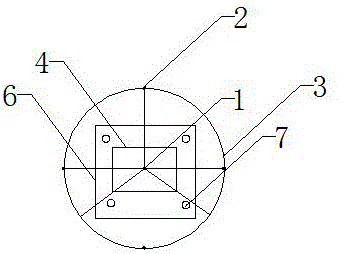

[0018] like figure 1 As shown in -2, a kind of optimization lightning rod comprises needle body and base, and described needle body is divided into main needle 1 and auxiliary needle 2, and described main needle 1 and auxiliary needle 2 are arranged on the lightning receptor 3, so The lightning receptor 3 is set on the base 4, the base 4 is provided with a screw hole 7, the base 4 is connected with the current limiting impedance 5, and the current limiting impedance 5 is set on the base 6 on.

[0019] The main needle 1 is arranged in the center of the lightning receptor 3 .

[0020] There are 4 auxiliary pins 2, which are arranged around the lightning receptor 3.

[0021] The said lightning receptor 3 is arranged in a circular shape.

[0022] The lightning receptor 3 is connected to the base 4 through threads.

[0023] The base 4 is connected to the current-limiting impedance 5 through screws.

[0024] The height of the main needle 1 should be higher than that of the auxilia

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap