Nitric acid-free pickling method for hot-rolled 201 austenitic stainless steel

An austenitic stainless steel, nitric acid technology, applied in the field of stainless steel pickling, can solve the problems of large acid consumption, natural environment and human production, activity hazards, nitrogen oxide waste gas and nitrogen-containing wastewater treatment costs increase, etc. The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

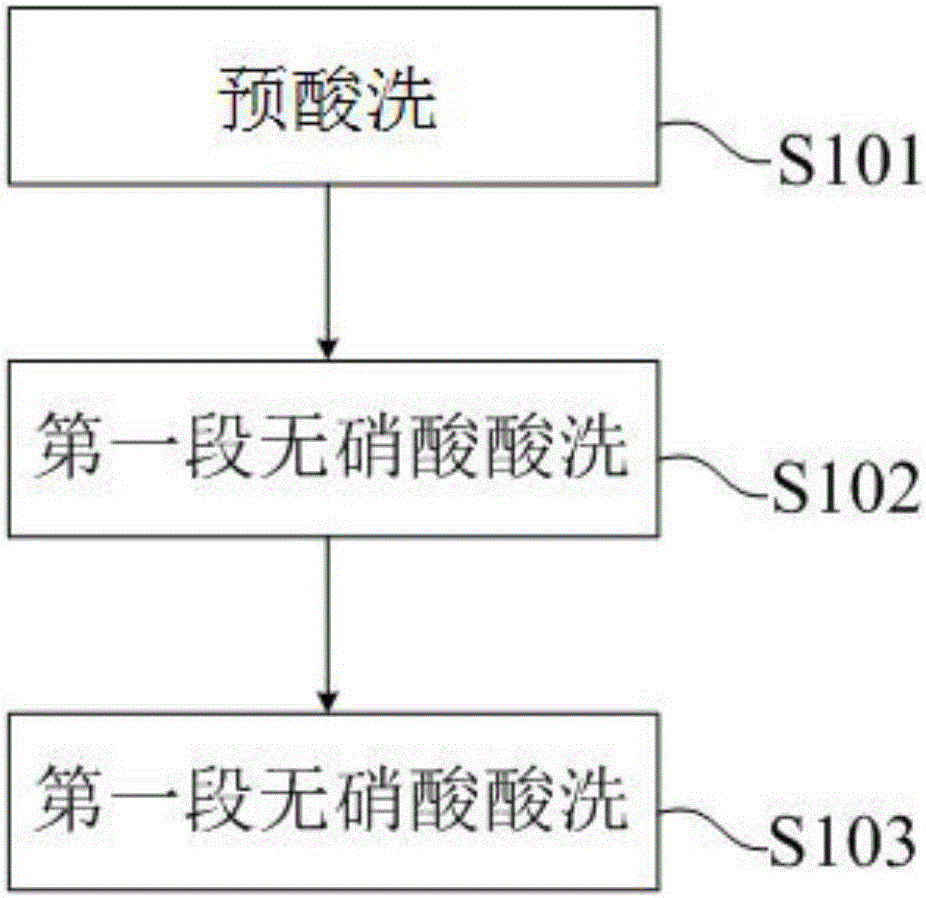

[0026] Such as figure 1 , the embodiment of the present invention relates to a nitric acid-free pickling method for hot-rolled 201 austenitic stainless steel, comprising the following steps:

[0027] (1) S101, pre-pickling step: dipping the steel strip into a pre-pickling solution for pickling. Among them, the pre-pickling liquid is preferably sulfuric acid pickling liquid, of course, other acid solutions, such as nitric acid, or a mixed acid solution of sulfuric acid and nitric acid, etc. can also be used. Taking sulfuric acid pickling as an example, in the sulfuric acid pickling solution, H 2 SO 4 The concentration is 150-170g / L, and the metal ion concentration is 30-40g / L. Among them, the temperature of the sulfuric acid pickling solution is preferably controlled within the range of 75-85°C, which can obtain better sulfuric acid pickling effect; the pickling time is preferably controlled within the range of 19-38s, which can control the steel strip from being overacidif

Embodiment 2

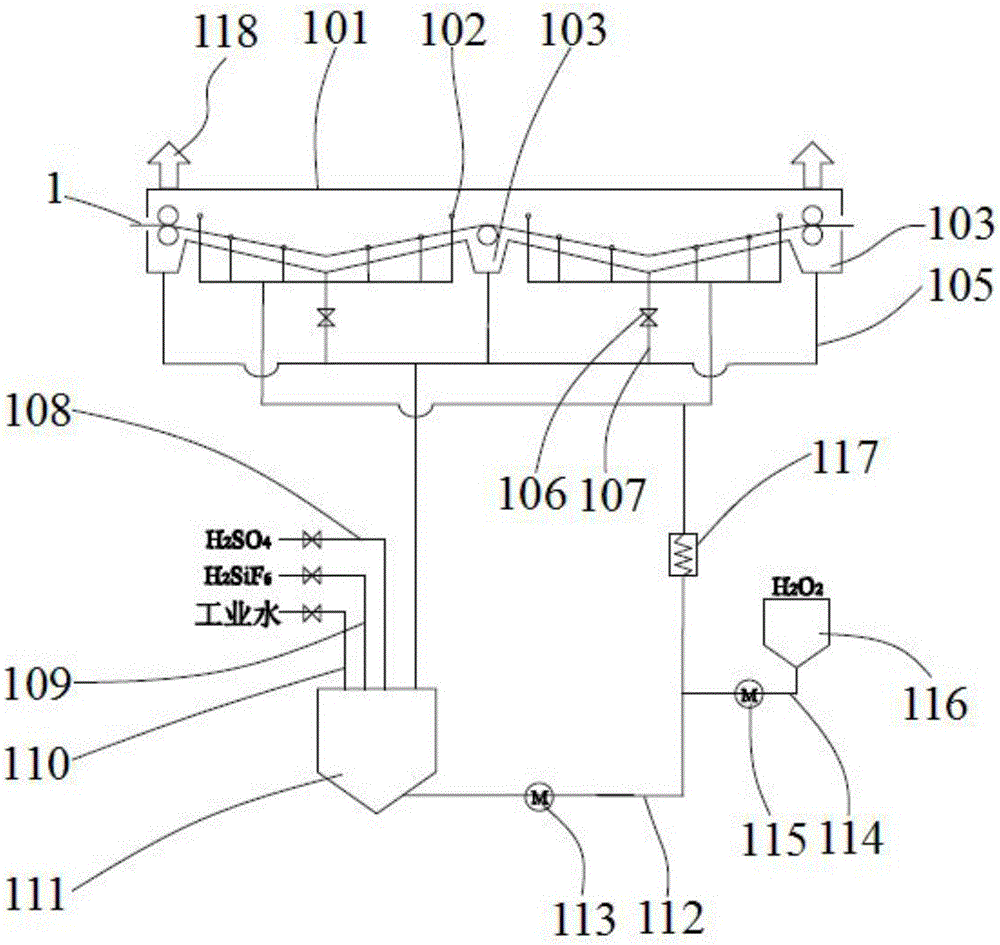

[0041] Such as figure 2 , the embodiment of the present invention provides a stainless steel pickling liquid supply mechanism for supplying pickling liquid to the nozzle 102 in the stainless steel strip pickling section, which includes an acid liquid supply pipeline 112, and the acid liquid supply pipeline 112 A pickling solution preparation structure is connected, and the pickling solution preparation structure includes a concentrated sulfuric acid distribution pipe 108, a water distribution pipe 110, a fluosilicic acid distribution pipe 109 and a hydrogen peroxide distribution pipeline 114; the above-mentioned concentrated sulfuric acid distribution pipe 108 is used to supply concentrated sulfuric acid , the water distribution pipe 110 is used to supply industrial water, the fluosilicic acid distribution pipe 109 is used to supply fluosilicic acid, and the hydrogen peroxide distribution pipeline 114 is used to supply hydrogen peroxide. The inlet end of the acid liquid supply p

Embodiment 3

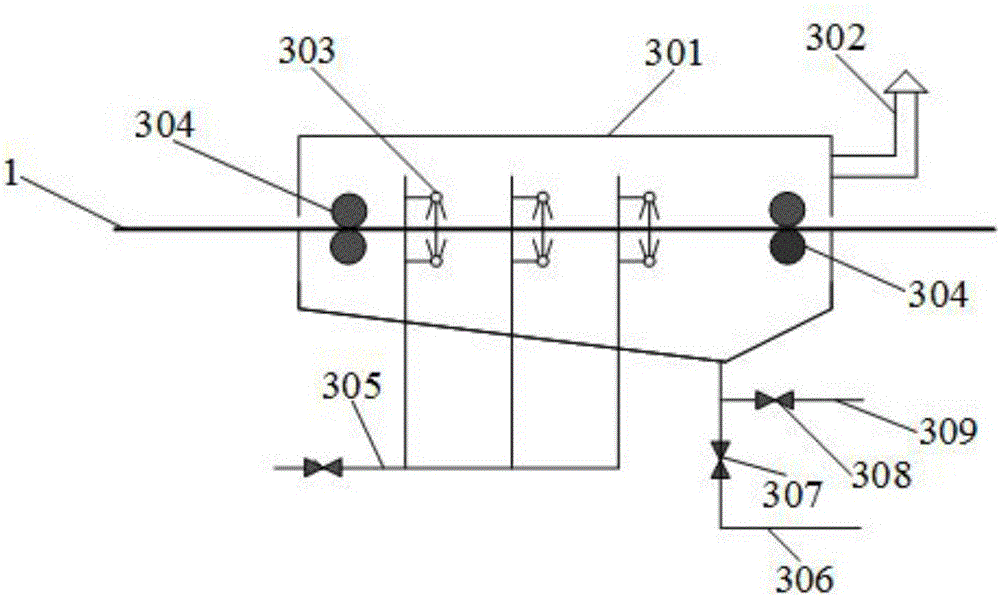

[0047] Such as image 3, this embodiment provides a strip steel preheating device before pickling, which can be used to preheat the strip steel 1 in the first embodiment above. The preheating device includes a preheating chamber 301, the openings at both ends of the preheating chamber 301 form a strip running passage through the preheating chamber 301, and the preheating chamber 301 is provided with a preheating chamber for preheating the steel strip 1. thermal body. The preheating chamber 301 is a closed box structure, and only two openings are provided to ensure the preheating effect of the strip steel 1 in the preheating chamber 301; the strip running channel formed by the restriction of the two openings is preferably a horizontal channel, wherein , in the preheating chamber 301, two sets of backup rolls 304 can be set, wherein one set of backup rolls 304 is arranged near the inlet end of the preheating chamber 301, and the other group is arranged near the outlet end of the p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap