Steam compressor

A compressor and steam technology, applied in the direction of machines/engines, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problems of polluted volute, efficiency drop, equipment failure, etc., and achieve sealing Good performance, improve production efficiency and avoid emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

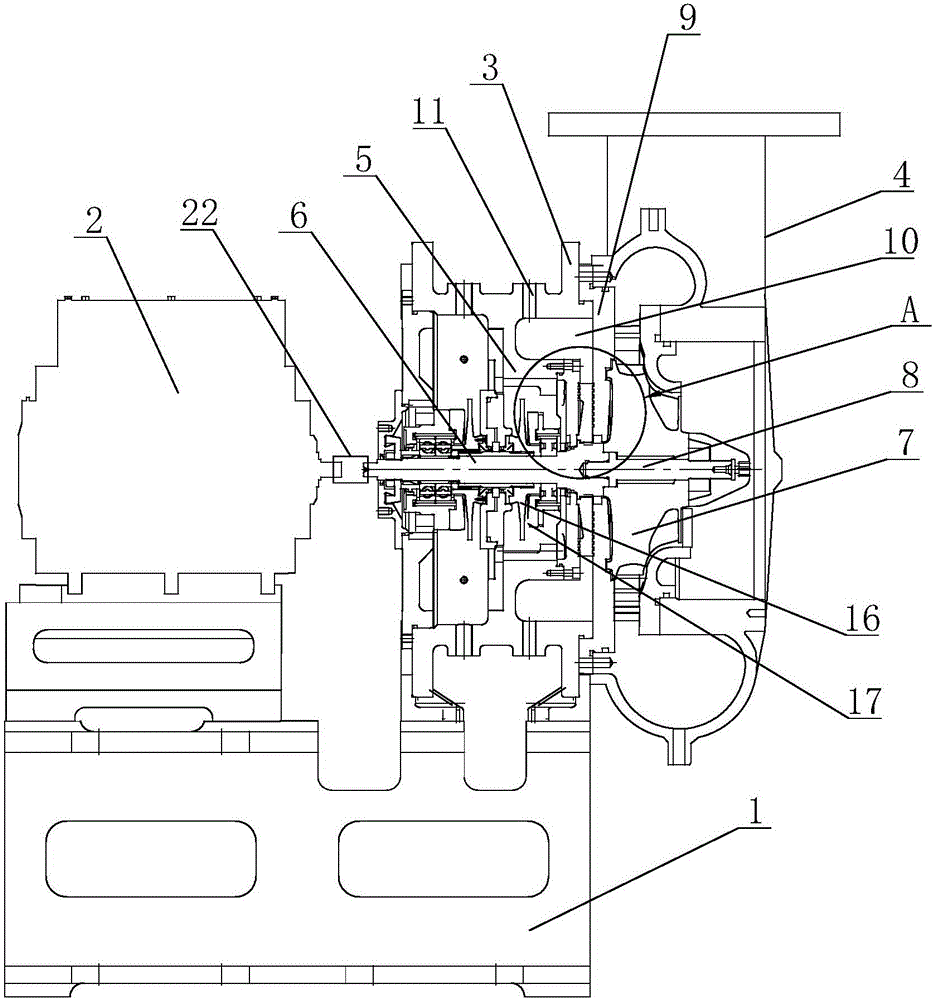

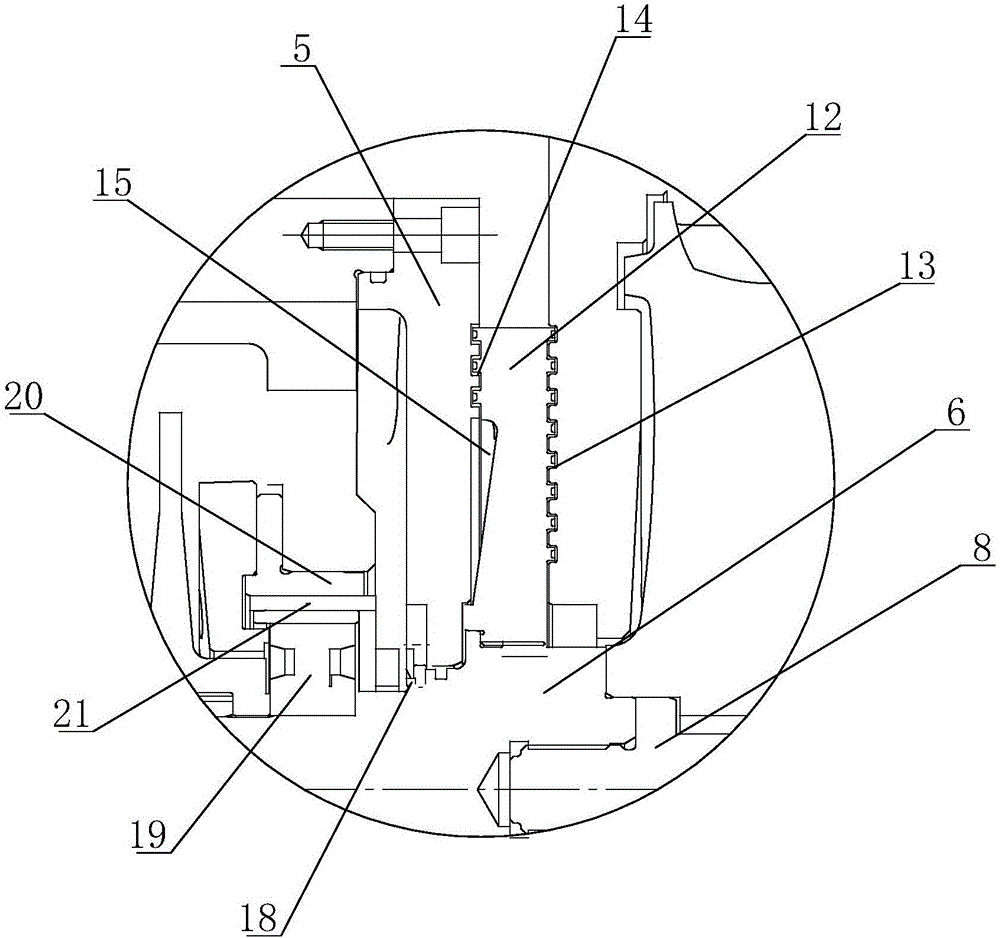

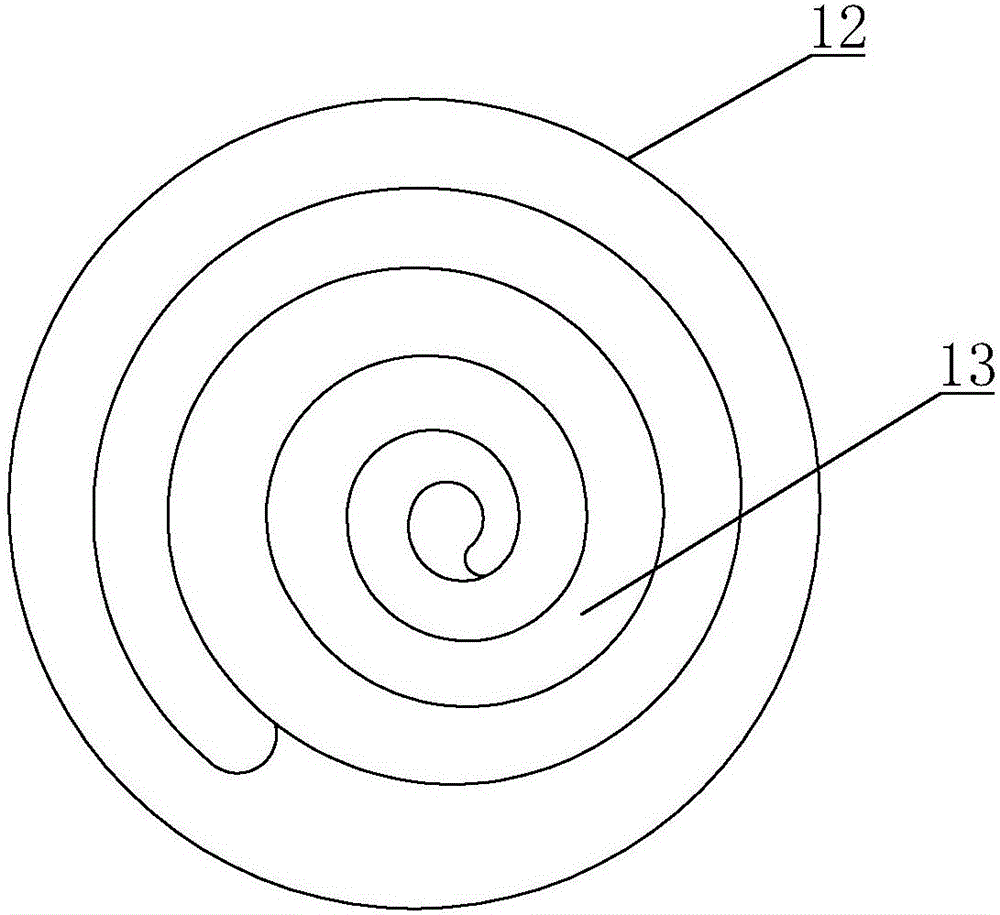

[0016] As shown in the figure, a vapor compressor includes a base 1, a motor 2, a casing 3, a volute 4, a transition box 5 and a main shaft 6, the transition box 5 is located in the casing 3, and the volute 4 is provided with There are blades 7 and blade shafts 8, a partition 9 is provided between the casing 3 and the volute, the main shaft 6 runs through the transition box 5 and is connected to the blade shaft 8 through the partition 9, and the partition 8 and A chamber 10 is provided between the transition box 5, a vent hole 11 communicating with the chamber 10 is provided on the housing 3, a sealing ring 12 is provided between the partition plate 9 and the transition box 5, and the sealing ring 12 is sleeved outside the main shaft 6, one end face of the sealing ring 12 is matched with the surface of the partition 9, the other end face is matched with the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap