Method for unloading wafer already subjected to surface process from silicon chip

A technology of wafers and silicon wafers, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as destroying the front pattern of the wafer, affecting the morphology of the electrode on the surface of the wafer and forward voltage parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

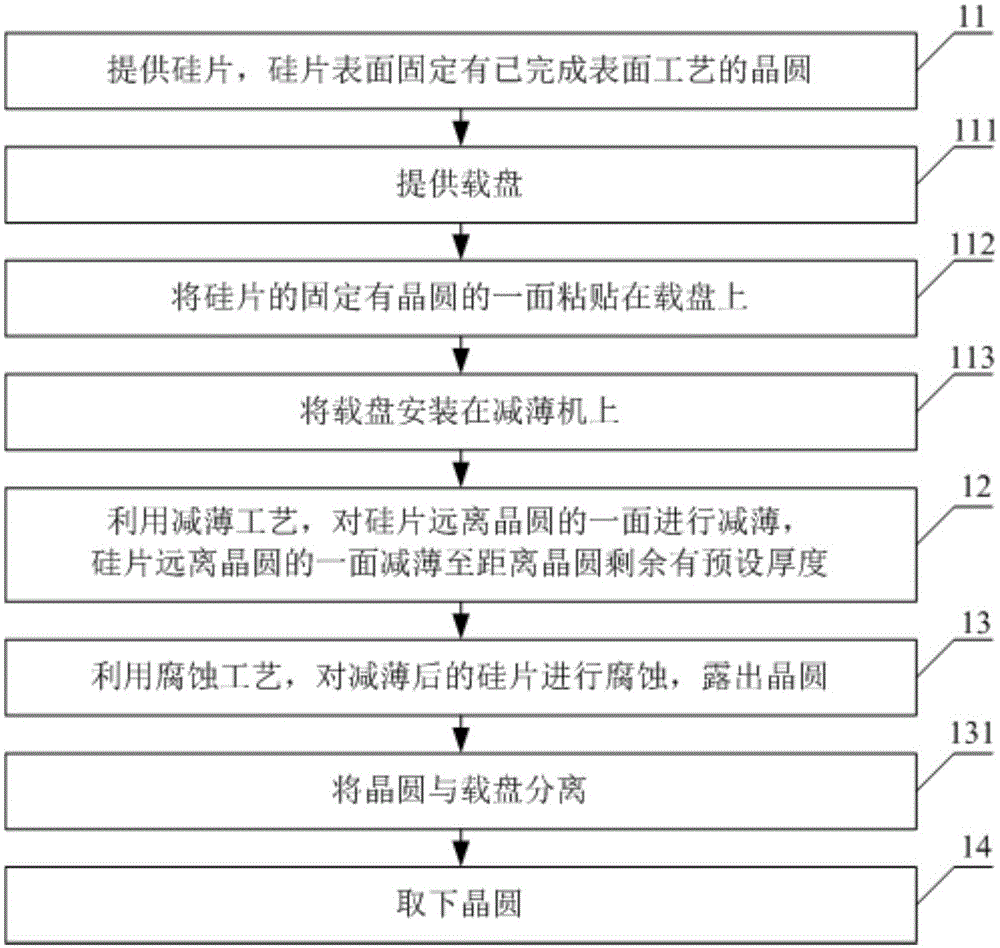

[0043] figure 1 It is a flow chart of a method for unloading a wafer that has completed a surface process from a silicon wafer provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0044] S11. Providing a silicon wafer, the surface of which is fixed with a wafer whose surface process has been completed.

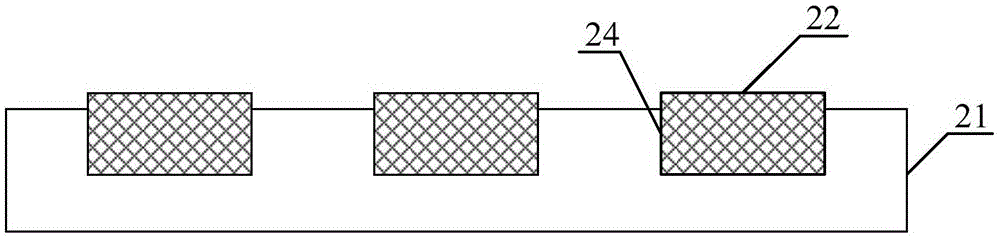

[0045] Such as figure 2 As mentioned above, the silicon wafer 21 in this embodiment is provided with at least one (only three are shown in the figure) wafer positioning grooves 24 , and the wafer 22 is fixed in the wafer positioning grooves 24 .

[0046] S12. Thinning the side of the silicon wafer away from the wafer by using a thinning process, the side of the silicon wafer away from the wafer is thinned to a predetermined thickness remaining from the wafer.

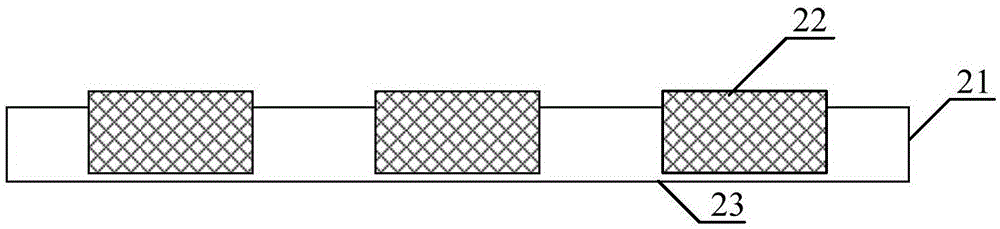

[0047] Such as image 3 As shown, there is remaining silicon 23 on the side away from the wafer 22 on the thinned silicon wafer 21 . The remaining

Embodiment 2

[0066] Figure 9 It is a flowchart of a method for unloading a wafer that has completed a surface process from a silicon wafer provided by Embodiment 2 of the present invention. Such as Figure 9 As shown, compared with the method of unloading the wafer with the completed surface process from the silicon wafer provided by the first embodiment of the present invention, this method only uses the thinning process to fix the wafer with the completed surface process. The silicon on the side of the silicon wafer away from the wafer is thinned until the wafer is exposed. At this time, since the silicon wafer has been thinned to expose the wafer, all the silicon on the side of the silicon wafer away from the wafer has been removed. Therefore, no further etching process is required to remove the remaining silicon on the side of the silicon wafer away from the wafer. Since no etching process is required, the impact of corrosion on the wafer can be completely avoided.

[0067] Compared w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap