Online automatic tidying system for test points of RODIP chains and swinging rod chains

A technology of test points and rod chains, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of weak cleaning effect and inability to disturb the brushing of the layer, and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

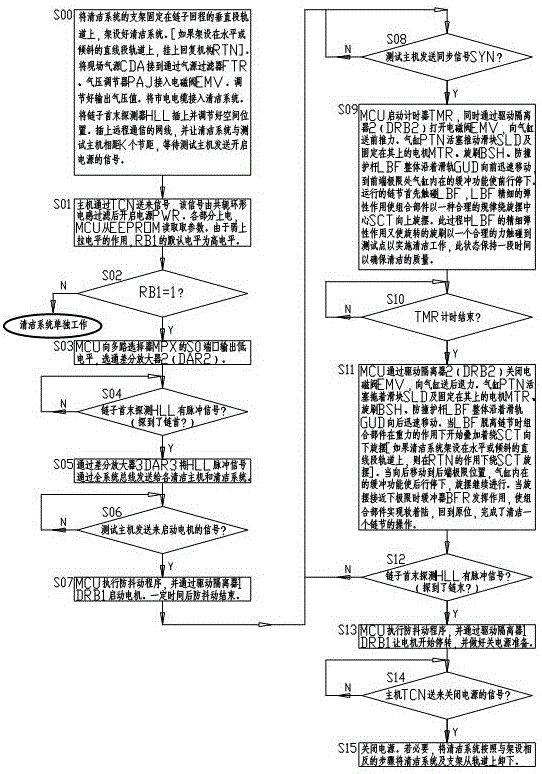

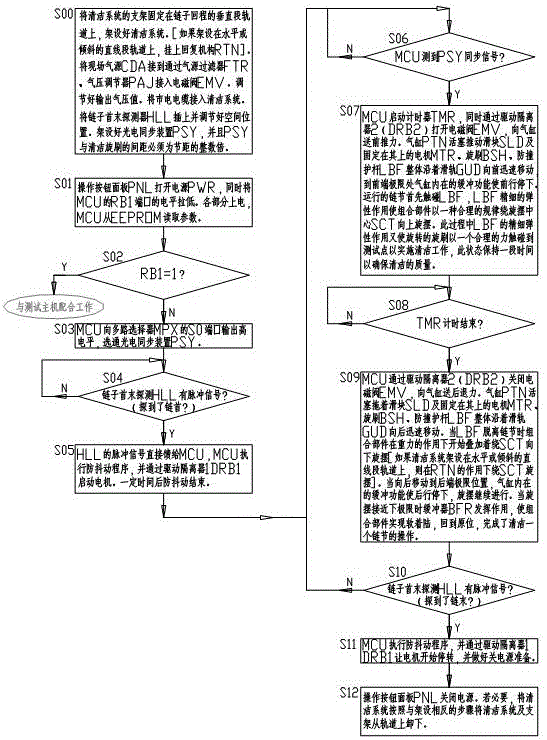

[0040] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

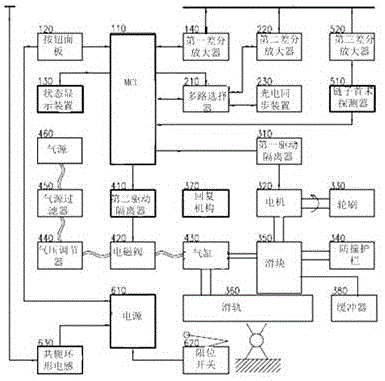

[0041] Such as figure 1 Shown, RODIP chain of the present invention and pendulum chain test point online automatic finishing system comprise:

[0042] MCU (micro-processing unit) 110 generates a synchronous signal and drives the cylinder with the synchronous signal;

[0043] Button panel 120, convenient for adjustment and selection;

[0044] Status display device 130, which displays the working status of the machine;

[0045] The first differential amplifier 140 connects the MCU with the remote device to ensure reliable communication;

[0046] Multiplexer 210, connected with MCU, for selecting the second differential amplifier or photoelectric synchronization device;

[0047] The second differential amplifier 220, under the premise of being selected by the multiplexer, loads the link sy

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap