Filtration type single screw extruder

A single-screw extruder and filtering technology, which is applied in the field of plastic extrusion processing, can solve the problems of product quality impact, failure to meet plastic recycling and other problems, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

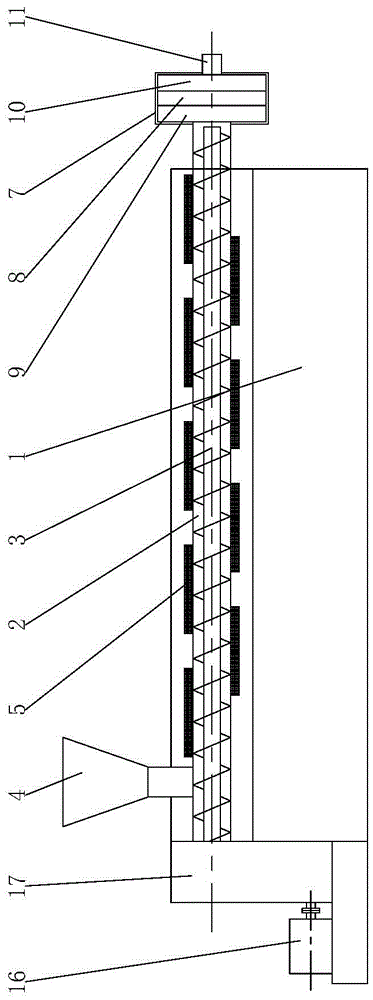

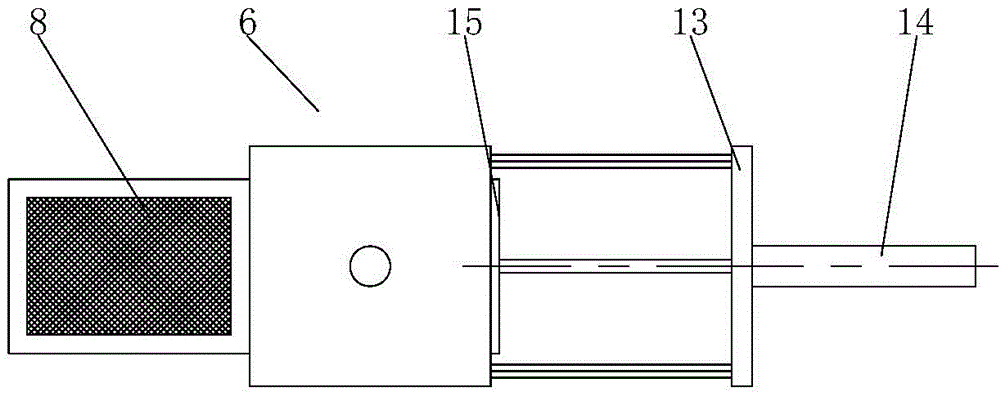

[0018] Such as figure 1 Shown is a schematic structural view of an embodiment of the filter-type single-screw extruder of the present invention. The filter-type single-screw extruder of this embodiment includes a body 1, an extrusion channel 2 is arranged in the body 1, an extrusion screw 3 is arranged in the extrusion channel 2, and an inlet communicating with it is provided on the extrusion channel 2. The hopper 4 is also provided with a heating device 5 for heating materials in the machine body 1 . The outlet end of extrusion channel 2 is provided with filtering device 6, and filtering device comprises housing 7, and is provided with filter element 8 in housing 7, and the two end

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap