Limit tire shovel device

A limit and limit column technology, applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of cumbersome operation and control, affecting the efficiency of tire shoveling, wasting energy, etc., to reduce manufacturing costs, save energy, The effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

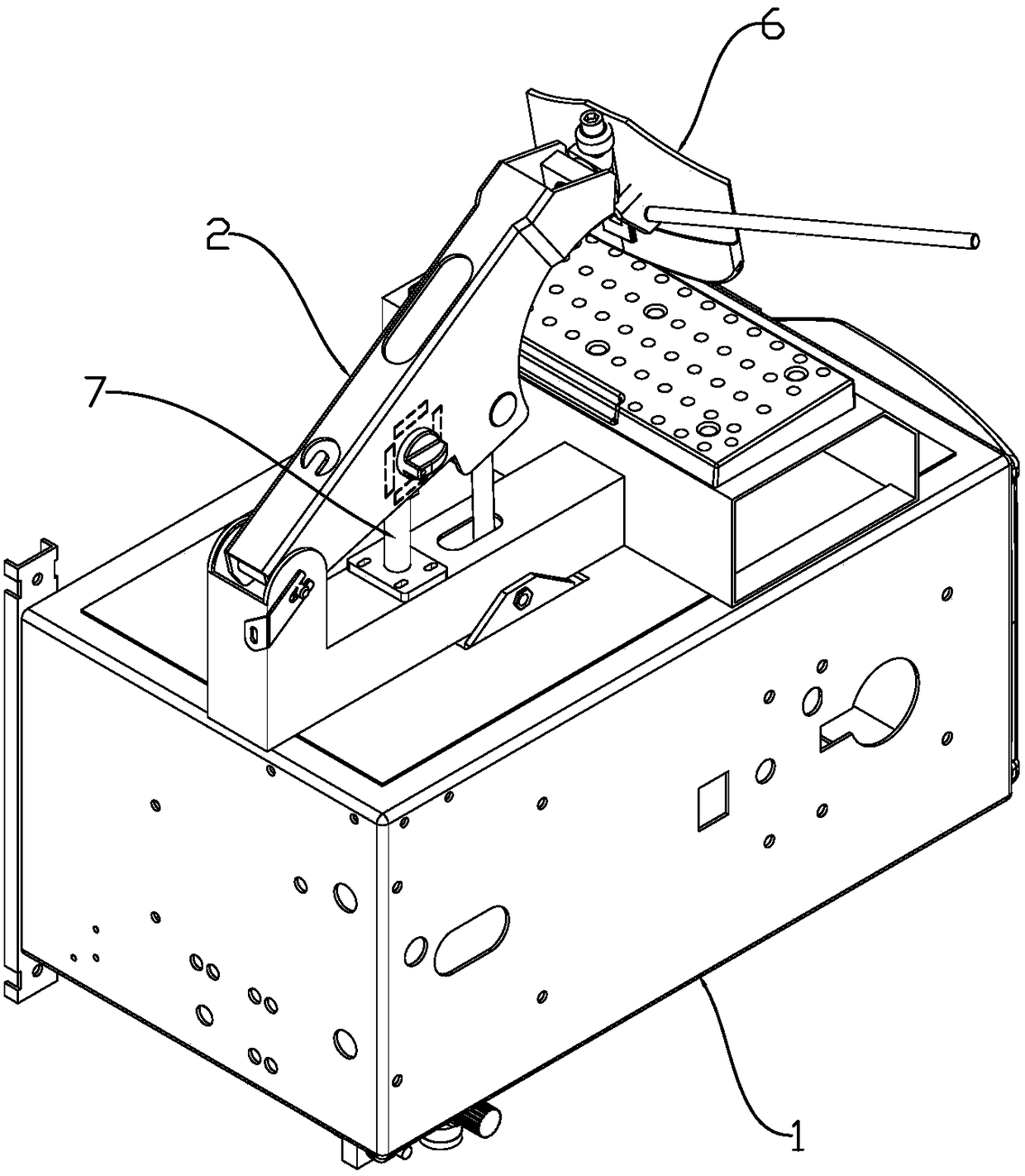

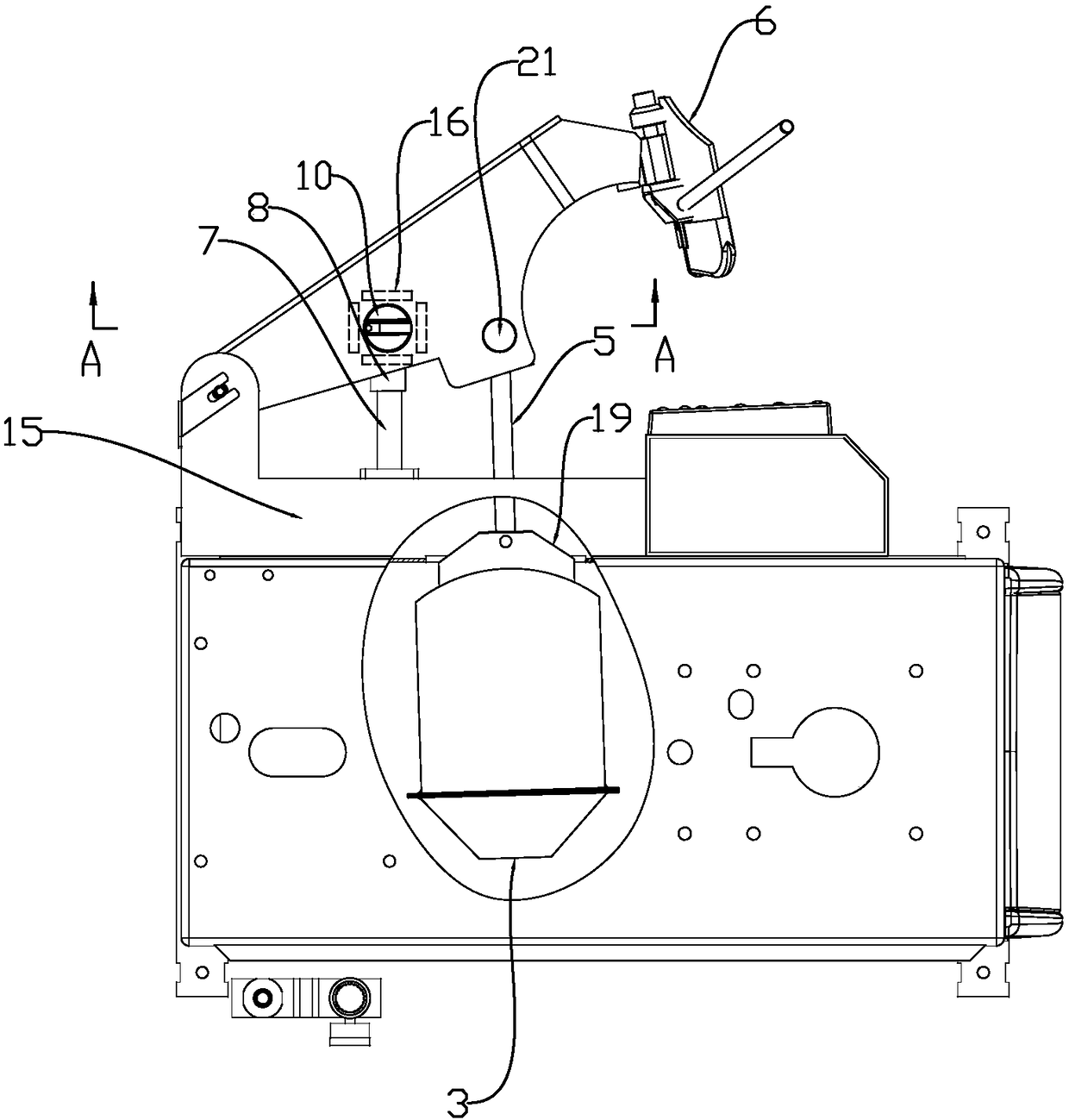

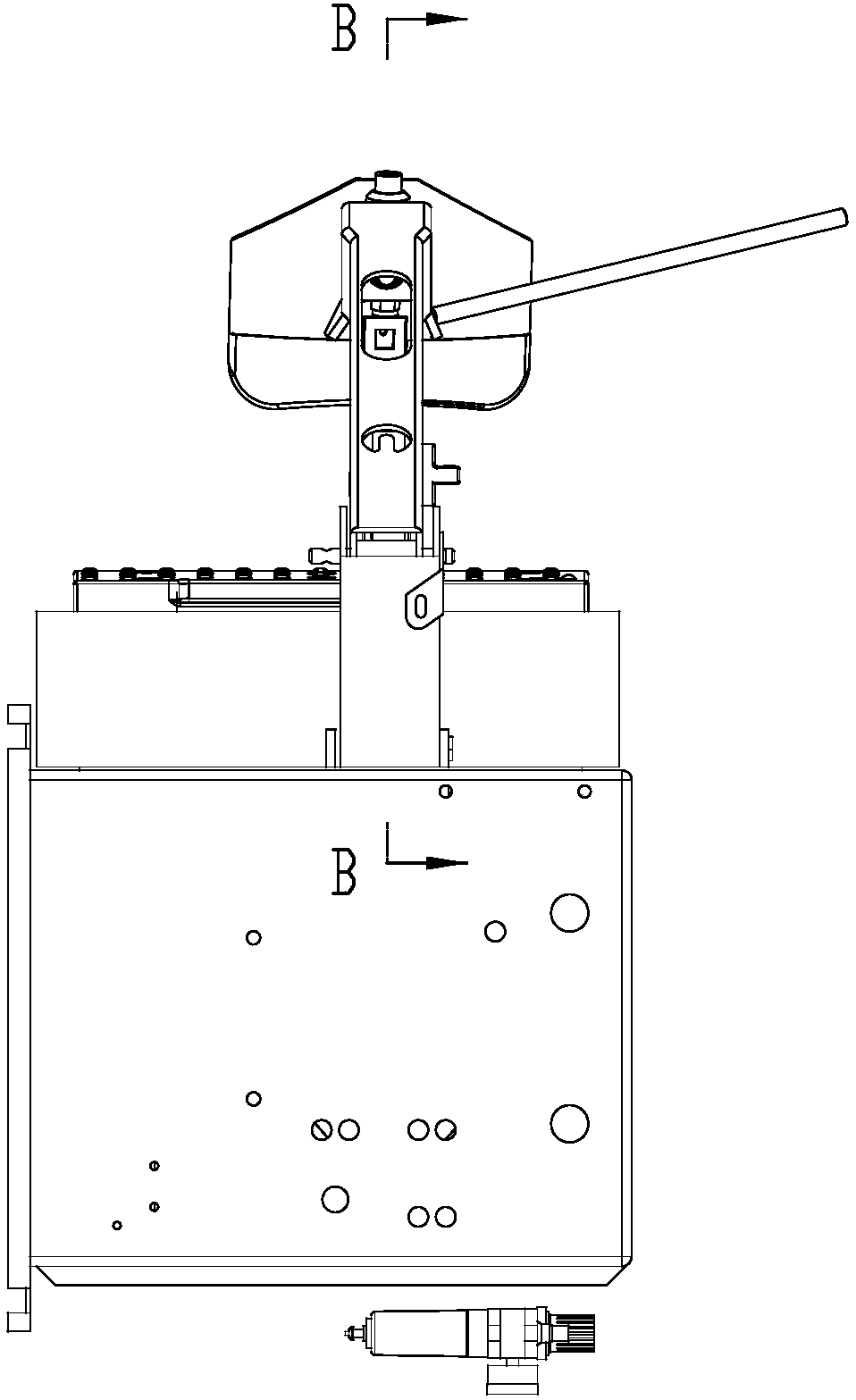

[0021] Such as Figure 1 to Figure 10 As shown, a limiting tire scraping device includes a box body 1 and a tire scraping frame 2. The box body 1 is provided with a cylinder 3, and the cylinder 3 is provided with a piston 4 and a piston 4 fixed and extending out of the box. The piston rod 5 outside the body 1, one end of the tire shovel frame 2 is provided with a shovel body 6, the end of the tire shovel frame 2 without a shovel body is hinged to the outside of the box body 1, and the piston rod 5 is connected to the shovel body The racks 2 are hinged to each other, and the piston rod 5 telescopic can drive the tire shovel frame 2 to rotate around the hinge joint of the tyre shovel frame 2 and the box body 1, and a tire shovel frame is provided between the box body 1 and the tyre shovel frame 2 to limit 2 The limit piece of the closing angle between the box body 1. An elastic member capable of resetting the piston 4 is provided in the cylinder 3. The elastic member in this embodi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap