Drying room used in workshop and plant

A drying room and factory building technology, which is applied in the direction of drying, dryers, and dryers for static materials, etc., can solve the problems of low space utilization rate of workshops and drying rooms, achieve the effect of improving utilization rate and ensuring aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

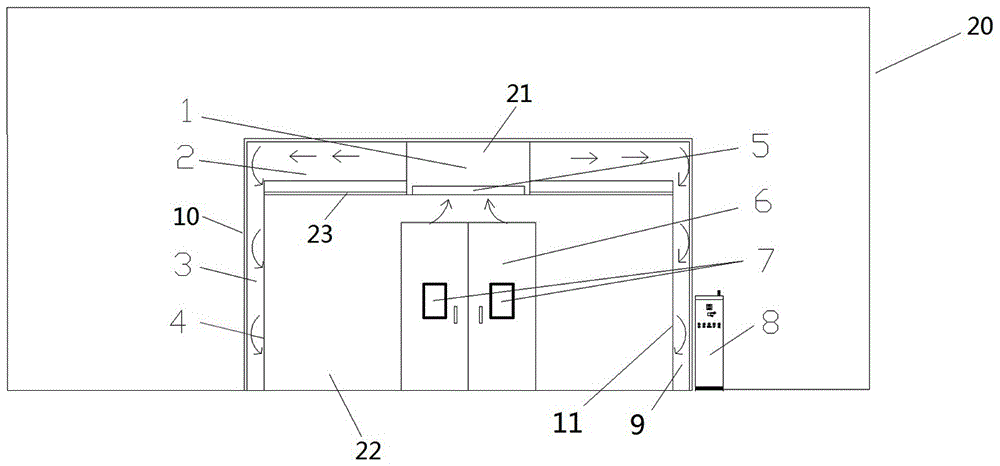

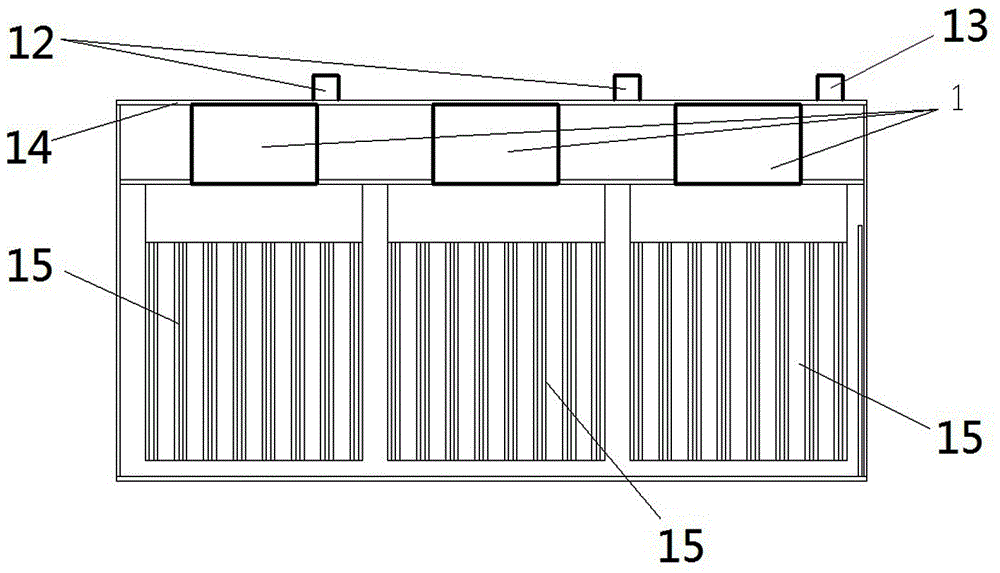

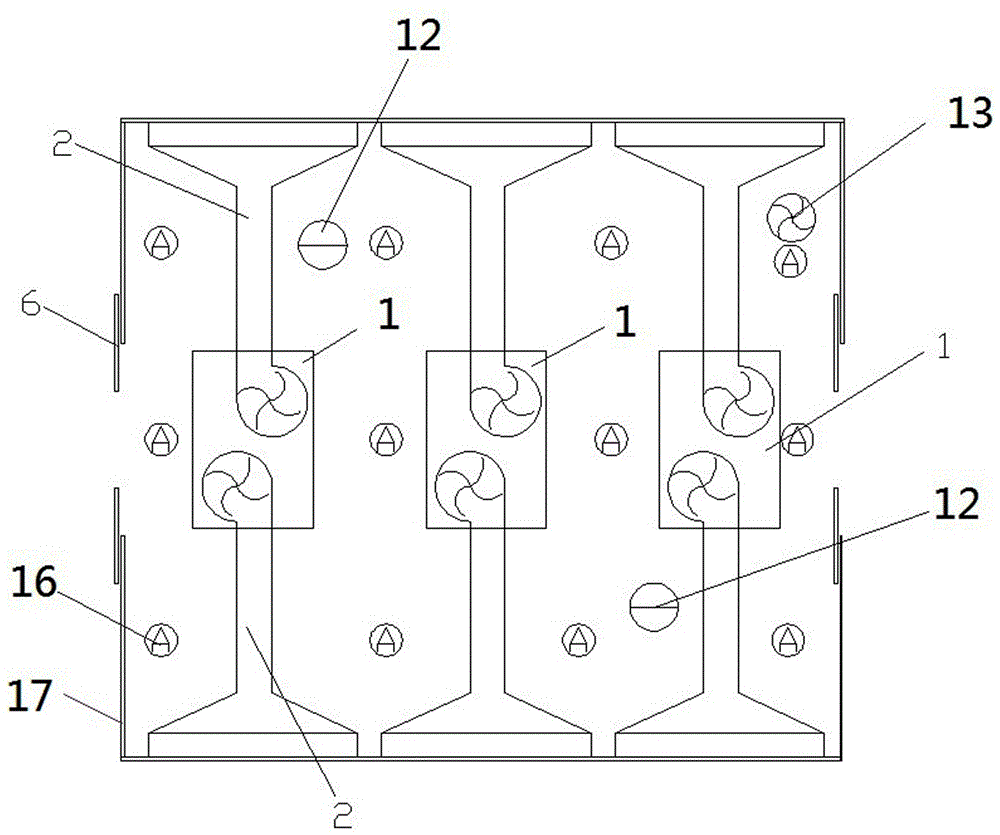

[0027] Workshop implementation example Figure 1~3 Shown: Including a factory building 20 and a drying room 17 set in the factory building. The drying room includes a concrete brick pouring house. The inner cavity of the house is divided into an equipment room 21 and a drying room 22 arranged up and down by a partition 23. The inner walls and partitions of the drying room are provided with thermal insulation layers. The left and right sides of the drying room 22 are provided with a left side wall 4 and a right side wall spaced apart from the left and right side walls of the drying room. 11. Both the front and back sides of the drying room are provided with door 6 for the objects to be dried in and out. There are three hot air devices 1 arranged sequentially in the front and rear directions in the equipment room. Air conditioning units and compressors (not shown in the figure) are also installed in the equipment room 21. Each hot air device 1 includes two independently controlled

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap