Earthing removing device for mine tunnel

A technology for removing devices and tunnels, applied in the direction of earthmoving machines/shovels, construction, etc., can solve the problems of reducing the service life of tooth bars and tooth tips, large working load, impact load, affecting enterprise benefits, etc., to facilitate excavation. and transport, reduce the resistance of undercutting, and improve the effect of undercutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

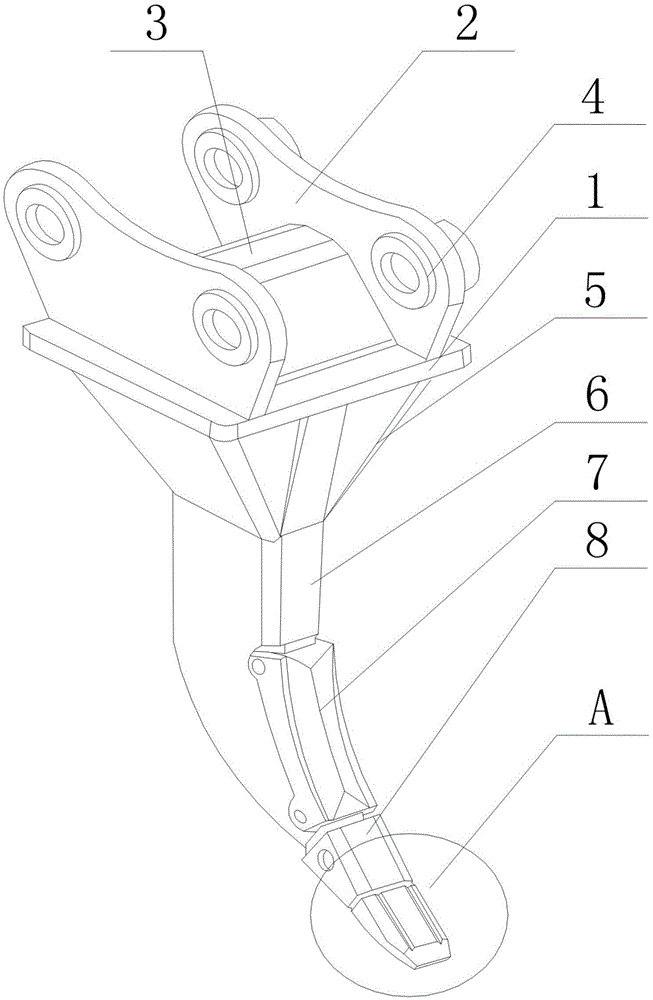

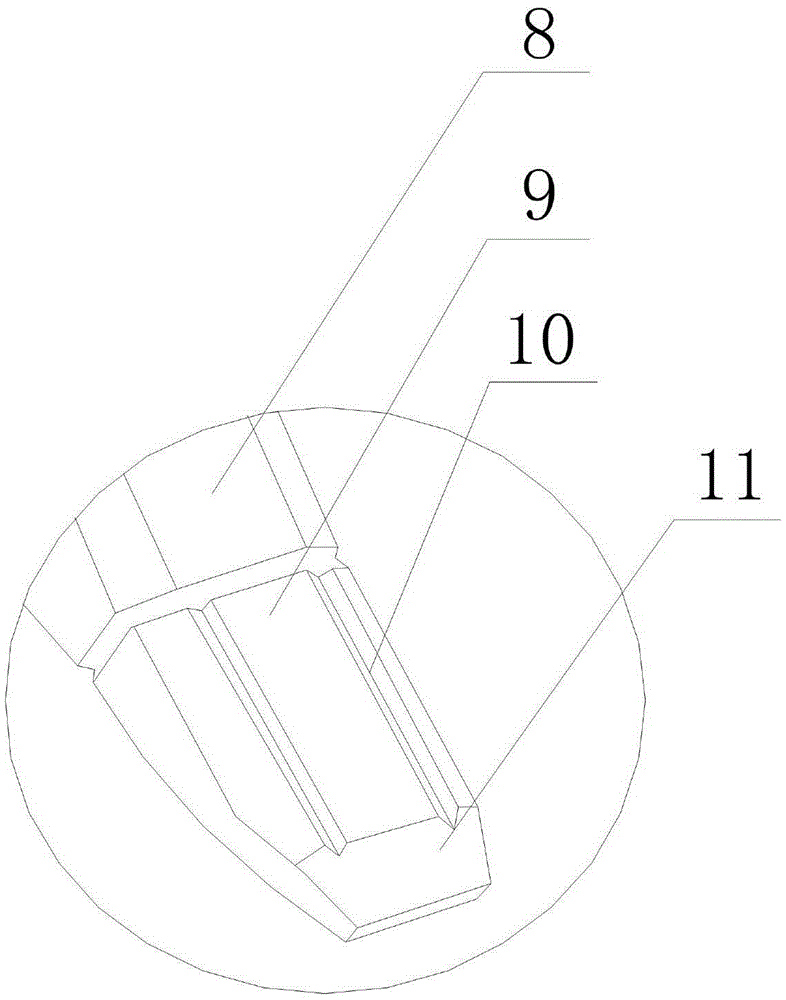

[0019] like figure 1 and figure 2 As shown, this embodiment includes a square connecting plate 1, ear plates 2 with shaft holes 4 are installed on both sides of the upper part of the connecting plate, and a trapezoidal reinforcing plate 3 is welded between the two ear plates 2, An arc-shaped gear bar 6 with bucket teeth 9 is welded at the middle of the bottom of the connecting plate 1, and a reinforcing plate 5 is welded between the square peripheral edge of the connecting plate 1 and the outer wall of the gear bar 6, An alloy sheath 7 is installed on the inner side of the arc-shaped curved surface of the tooth bar 6 through a pin shaft, and a gear sleeve 8 is installed on the upper part of the bucket tooth 9 through a pin shaft. An arc-shaped diversion groove 10, and the diversion groove 10 extends along the direction from the bottom of the bucket tooth 9 to the bottom of the tooth sleeve 8, and the depth of the diversion groove 10 increases along its extending direction. Dur

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap