Board multi-blade saw sorting machine

A multi-blade sawing and board technology, applied in grading, circular sawing, solid separation, etc., can solve the problems of increasing labor costs and reducing production efficiency, and achieve the effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

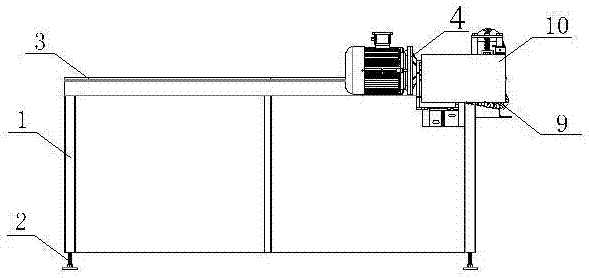

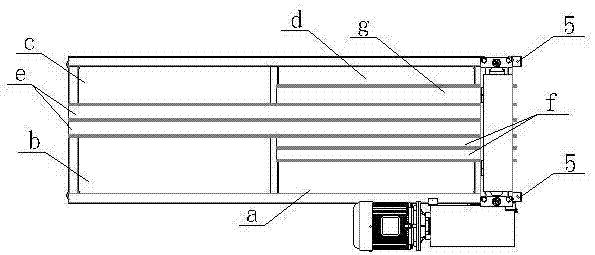

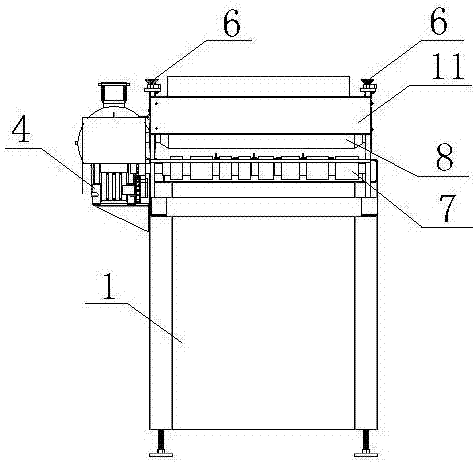

[0014] Such as Figure 1-3 As shown, a multi-blade saw for plate cutting, which includes a frame (1), is characterized in that it also includes a tripod (2), a workbench (3), a geared motor (4), a connecting block (5), an adjustment Switch (6), main transmission shaft (7), pressing shaft (8), transmission sprocket group (9), motor cover (10), pressure wheel cover (11); it is characterized in that the frame (1) The tripod (2) is installed on the bottom surface; the right end of the frame (1) is equipped with a deceleration motor (4) connecting block (5) adjusting switch (6) main drive shaft (7) pressing shaft (8) transmission sprocket group (9) motor cover (10) pressing wheel cover (11); the upper end of the pressing shaft (8) is equipped with an adjustment switch (6); the geared motor (4) passes through the transmission sprocket group ( 9) It is connected with the main drive shaft (7); the motor cover (10) is installed on the reduction motor (4); the pressure roller cover (11) i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap