Rounded corner triangle graphical substrate

A patterned substrate and triangular technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high-quality growth and epitaxy, small gaps, etc., to broaden the process window, improve light extraction efficiency, and large pattern gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

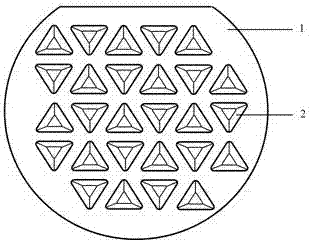

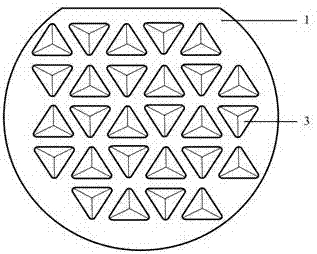

[0025] In this embodiment, the rounded triangle patterned substrate, such as figure 1 , 2 As shown in and 3, a sapphire substrate 1 is included, and the surface of the substrate 1 has periodic protrusions or depressions formed by a nanoimprint method. The length of the radian of the vertex angle is 0-500 nm.

[0026] In the embodiment, the rounded triangles are in a compact arrangement, that is, the perpendicular bisector of any side of each arranged rounded triangle passes through the center of the rounded triangle and the corresponding adjacent rounded triangle, and the adjacent rounded triangles are within the error range There is the same gap between them, the gap is 50-1000nm, and any side of the rounded triangle is arranged symmetrically with the side corresponding to the adjacent rounded triangle with respect to the gap axis; as an example, a more specific implementation is the period of the periodic pattern The length is 100-8000nm, the length of the bottom side of the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap