Device for inoculation and bagging and inoculation method of edible oyster mushroom

A bagging device and edible fungus technology, applied in the fields of botanical equipment and methods, application, horticulture, etc., can solve the problems of single machine inoculation method, low efficiency of manual inoculation and bagging, unstable machine inoculation quality, etc. The consumption of manpower, the efficiency of inoculation and bagging, and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

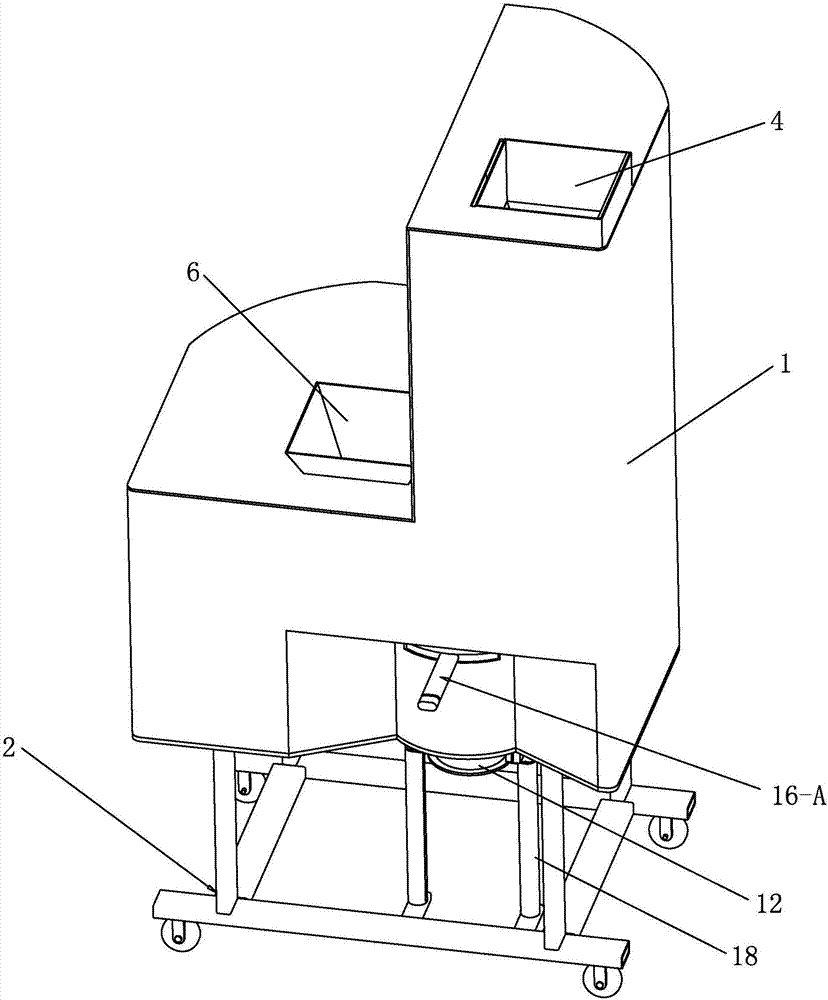

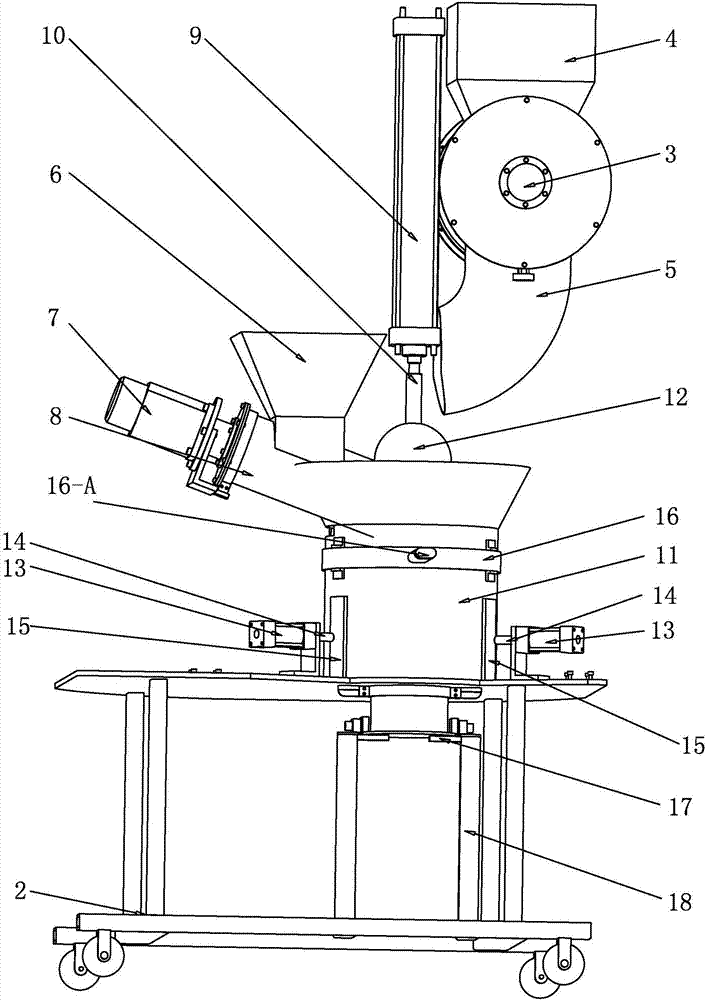

[0043] Specific implementation mode one: see Figure 1-Figure 12 Describe, a kind of oyster mushroom edible fungus inoculation bagging device, it comprises frame, frame base, strain crushing device, culture medium feeding device and bagging device;

[0044] The frame 1 is installed on the frame base 2, the strain crushing device and the culture medium feeding device are arranged on the frame 1, and the bagging device is arranged on the frame base 2;

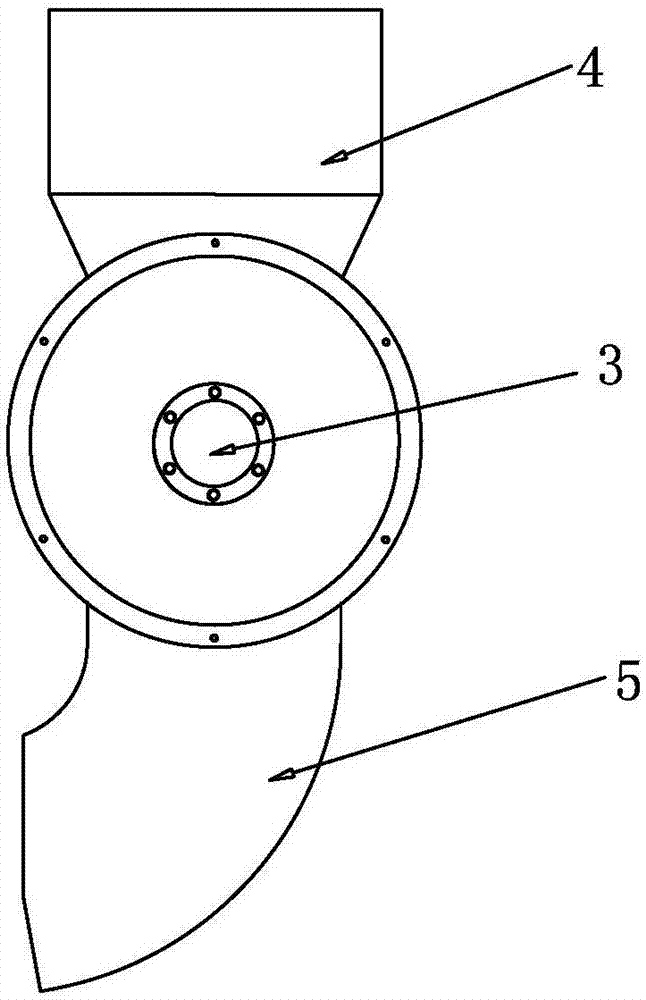

[0045] The strain crushing device comprises a crushing shaft 3, a crushing bin 4 and a feeding pipeline 5; the crushing bin 4 is installed on the frame 1, and the bottom of the crushing bin 4 is connected with the feeding pipeline 5; the middle part of the crushing bin 4 is equipped with a power Motor-driven smashing shaft 3;

[0046] Described culture medium feeding device comprises feeding hopper 6, motor 7 and screw feeding device 8; The screw feeding device 8 driven by motor 7 is installed on the frame 1, is positioned at the s

specific Embodiment approach 2

[0050] Specific implementation mode two: see Figure 4 Note that four groups of crushing teeth are evenly distributed along its circumference on the surface of the crushing shaft 3, and each group has N pieces of crushing teeth; the positions of the first group and the third group of crushing teeth correspond to each other, and the positions of the second group and the fourth group The positions of the crushing teeth correspond to each other, and the positions of the first and third groups of crushing teeth and the second and fourth groups of crushing teeth are mutually staggered. With such a design, the strain rod can be broken more fully. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] Specific implementation mode three: see image 3 and Figure 4 Explain that the inlet of the feeding pipeline 5 in this embodiment is provided with several feeding ports with a width of 10 mm and a length matching the size of the circular section at the inlet of the feeding pipeline 5 . With such a design, the bacteria fragments that fail to meet the requirements can be further crushed until they reach the required size. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap