Display device, array substrate and manufacturing method thereof

An array substrate and manufacturing method technology, applied in the display field, can solve the problems of shrinking, approaching the limit, and the inability to effectively realize the ultra-narrow frame of the panel, so as to achieve the effect of reducing the area and designing the ultra-narrow frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below by means of drawings and embodiments.

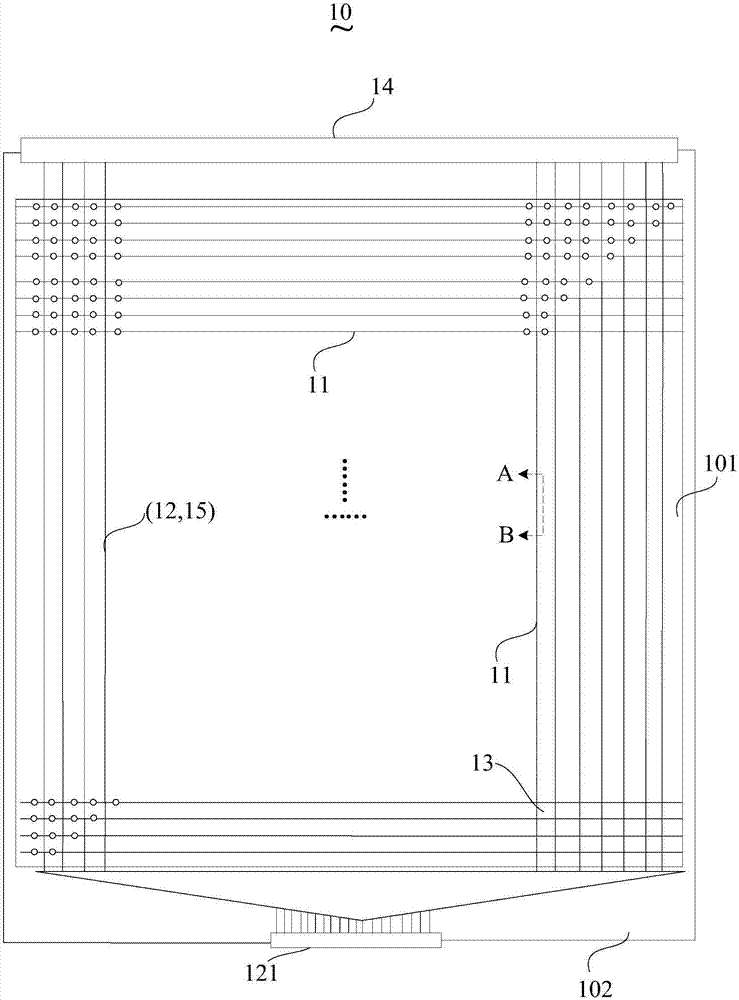

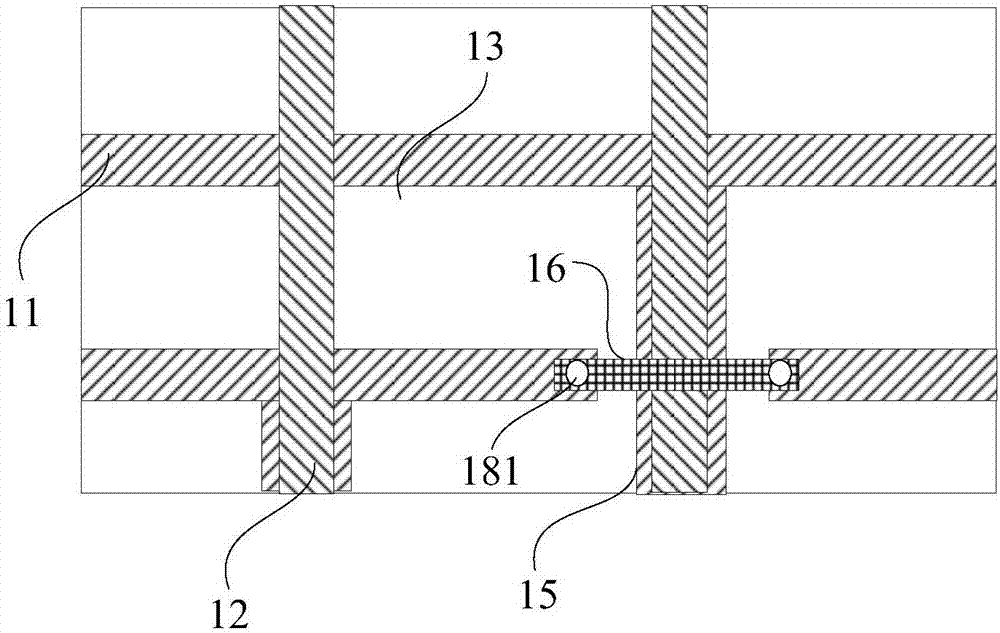

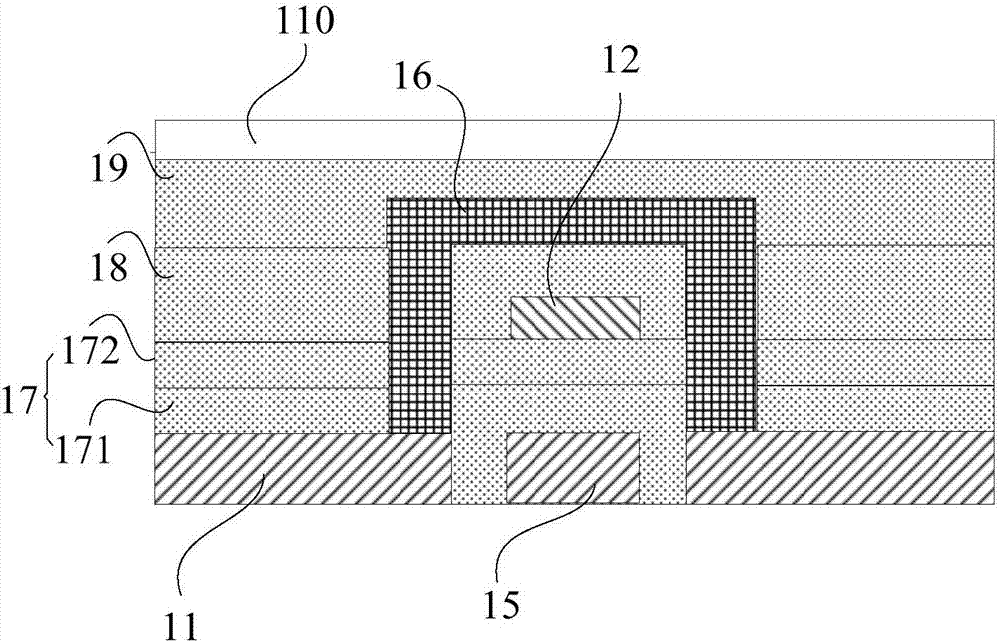

[0016] see figure 1 and image 3 , figure 1 is a schematic structural view of an array substrate provided by an embodiment of the present invention, figure 2 is a partial structure diagram of an array substrate provided by an embodiment of the present invention, image 3 is a schematic cross-sectional structure diagram of an array substrate provided by an embodiment of the present invention. The array substrate 10 includes a display area 101 and a non-display area 102 . The display area 101 is provided with multiple scan lines 11 , multiple data lines 12 intersecting the multiple scan lines 11 , and multiple pixel units 13 surrounded by the intersecting scan lines 11 and data lines 12 . The non-display area 102 is provided with a driving circuit 14 for providing a driving signal to the scan line 11 and a driving circuit 15 for providing a data voltage signal to the data...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap