Welding jig for exhaust manifold heat dissipation auxiliary fixing frame

An exhaust manifold, welding fixture technology, applied in auxiliary welding equipment, auxiliary devices, welding equipment and other directions, can solve the problems of poor welding effect, damage to brackets or flanges, relative movement of flanges and bracket mounting parts, etc. To avoid unstable fixation, avoid injury, and facilitate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

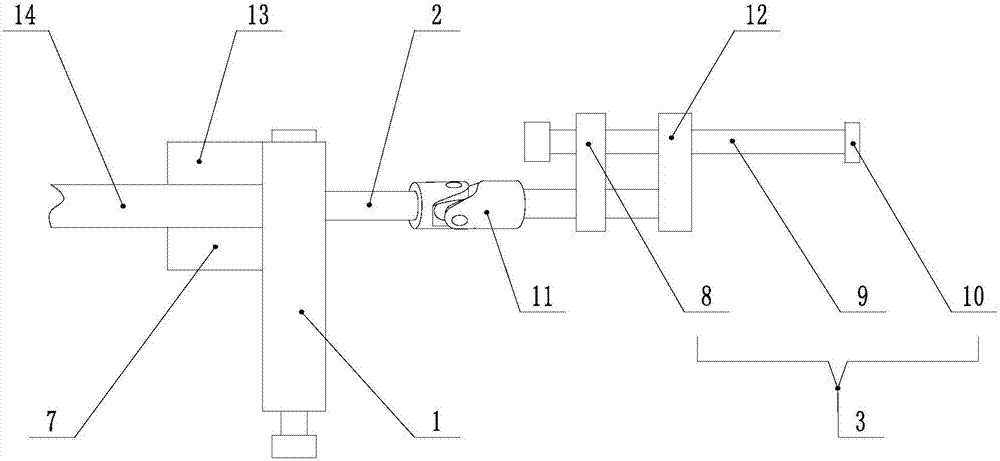

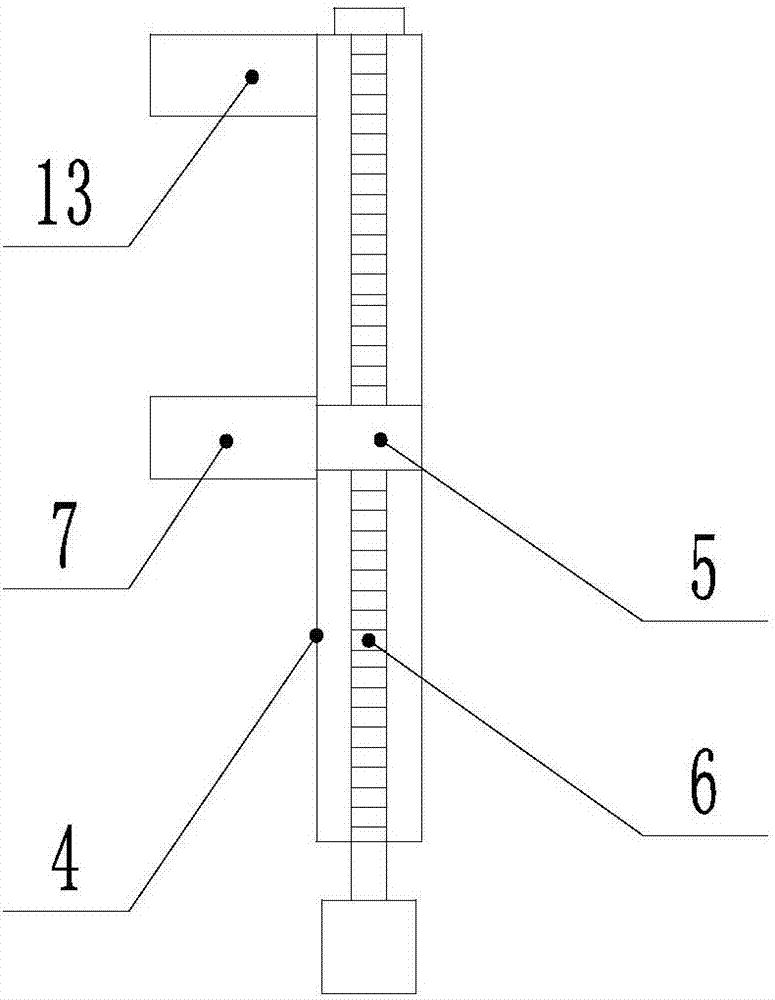

[0023] Such as Figure 1 ~ Figure 2 As shown, the welding fixture for the exhaust manifold heat dissipation auxiliary fixing frame of the present invention includes a fixed part 1, a connecting part 2 and a pressing part 3 connected in sequence, a guide groove 4 is arranged on the fixed part 1, and a The moving block 5 is provided with a screw-6 through the moving block 5, the moving block 5 and the screw-6 are screwed together, and the moving block 5 can move along the screw-6, the moving block 5 is provided with a fixed plate 7, and one end of the guide groove 4 A baffle 13 is provided, and the fixed part 1 is placed on the workbench 14, so that the workbench 14 is located between the fixed plate 7 and the baffle 13, and the screw one 6 is rotated to make the moving block 5 and the fixed plate 7 move along the screw one 6 , that is, the moving block 5 and the fixed plate 7 move along the guide groove 4, so that the fixed plate 7 and the baffle plate 13 clamp the workbench 14...

Embodiment 2

[0026] The present invention is based on embodiment 1, and the present invention is further described.

[0027] Such as figure 1 As shown in the present invention, the welding fixture for the exhaust manifold heat dissipation auxiliary fixing frame, the connecting part 2 is a telescopic rod, and the telescopic rod adopts a common telescopic rod structure on the market, which is used to adjust the length of the connecting part 2 to make it more applicable. The connecting part 2 is provided with a steering mechanism 11, and the steering mechanism 11 can be fixed by a fastener, which is used to adjust the position of the pressing part 3 according to the connection situation of the flange and the mounting part of the support frame, so that the pressing plate 10 has a better pressing effect on the mounting part of the support frame, and the steering mechanism 11 is a universal joint.

Embodiment 3

[0029] The present invention is based on embodiment 1, and the present invention is further described.

[0030] Such as figure 1 As shown, the welding fixture for the exhaust manifold heat dissipation auxiliary fixing frame of the present invention, the guide plate 8 is also connected with the auxiliary guide plate 12, the screw rod two 9 is screwed with the auxiliary guide plate 12, and the screw rod two 9 is simultaneously connected with the guide plate 8 and the auxiliary guide plate The plate 12 is screwed together, so that the movement of the second screw 9 is more stable, the direction is fixed, and shaking is not easy to occur.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap