Single-nickel salt coloring filter, circulating filtering system and filtering method

A technology of cyclic filtration and filtration method, which is applied in the field of filtration, can solve problems such as operational errors, inconvenient operation, and waste, and achieve the effects of automatic cleaning, time saving, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

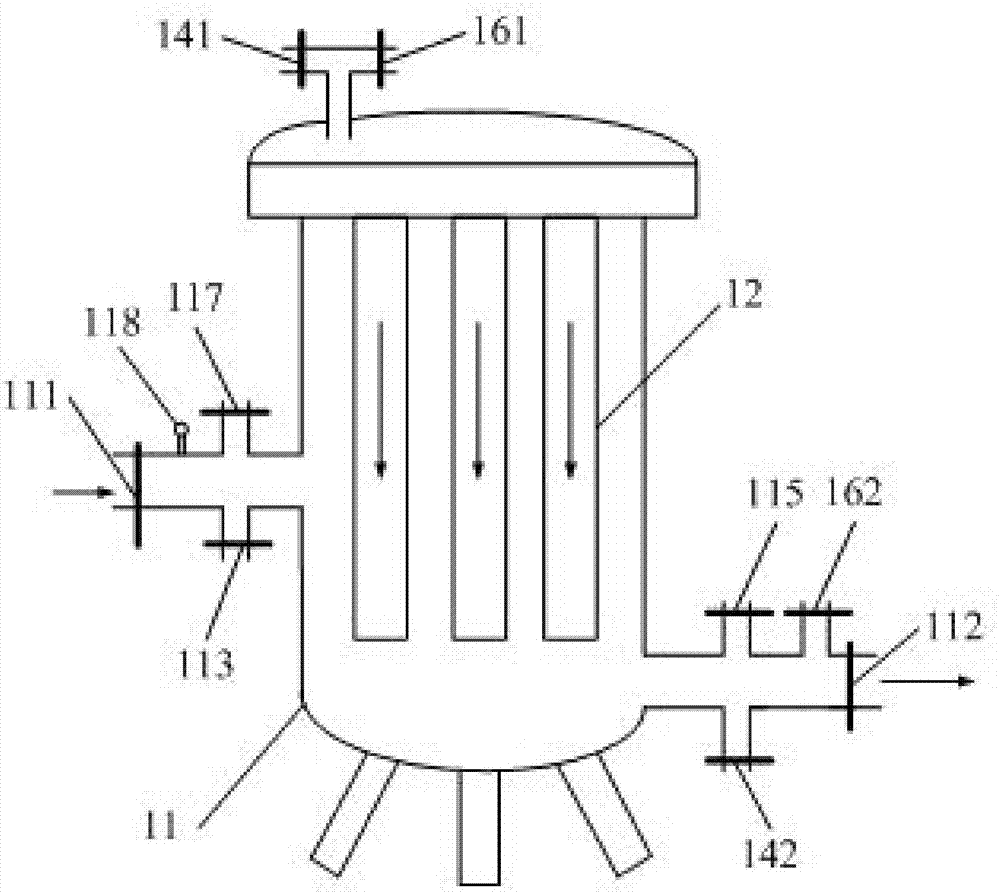

[0040] Such as figure 1 As shown, the present invention also provides a single nickel salt colored filter 1, comprising: a filter body 11 and a filter element 12;

[0041] The filter body 11 includes a liquid inlet solenoid valve 111 connected with the auxiliary tank, a liquid outlet solenoid valve 112 connected with the main tank, an air solenoid valve 113 connected with the compressed air pipeline, a waste water solenoid valve connected with the waste water pipeline, and a The acid liquid solenoid valve 115 connected to the acid storage tank, the chemical liquid solenoid valve connected to the medicine dosing tank, the pure water solenoid valve 117 connected to the pure water pipe and the pressure sensor 118, wherein,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap