Spiral flow type suspension bed reaction device

A technology of a reaction device and a suspended bed, which is applied in the field of a swirl-type suspended bed reaction device, can solve problems such as low fluid linear velocity, solid material deposition, and poor reaction effect, and achieve enhanced heat and mass transfer effects, improved performance, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention is described in detail in conjunction with the accompanying drawings.

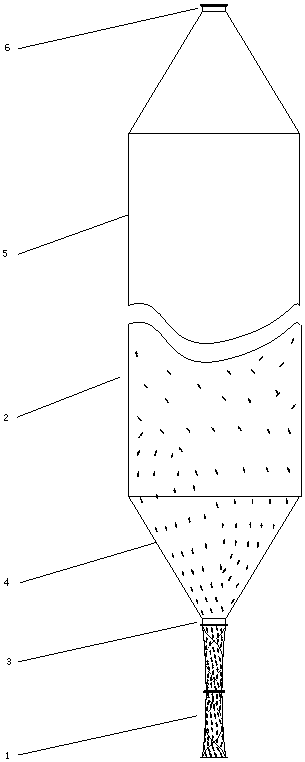

[0029] This embodiment provides a swirl-type suspended bed reactor, including: a swirl generator 1 and a suspended-bed reactor 2 .

[0030] The suspended bed reactor is composed of successively connected reactor inlet 3, reactor conical bottom 4, reactor cylinder 5 and reactor outlet 6; the diameter of the reactor conical bottom gradually increases towards the reactor inlet. Convergence; the cone angle of the conical bottom of the reactor is 30-120°;

[0031] The outlet of the swirl generator is connected to the inlet 3 of the suspended bed reactor through a flange or thread connection;

[0032] The swirl generators are 2 connected in series;

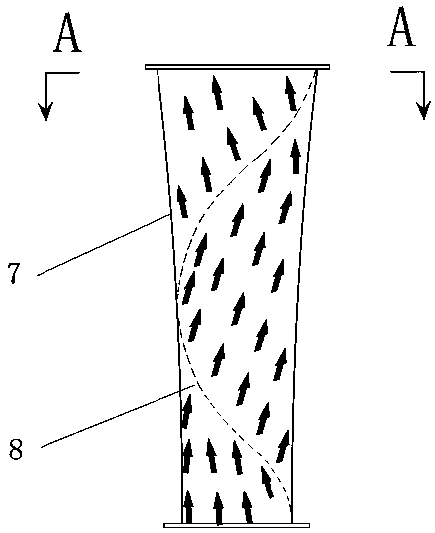

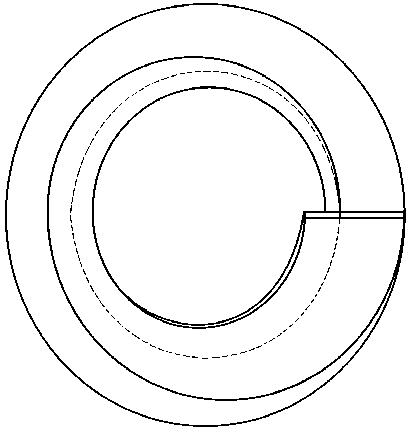

[0033] The swirl generator is composed of a housing 7 and a helical structure 8 arranged on the inner wall of the housing, and the axial length of the helical structure is equal to the axial length of the housing;

[0034] The ratio of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap