Bucket cover self-locking device

A technology of self-locking device and barrel cover, which is applied in packaging, locking equipment, transportation and packaging, etc. It can solve the problems of poor safety and reliability, lack of self-locking device for barrel covers, etc., so as to improve work efficiency and ensure equipment stability , The effect of simplifying the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

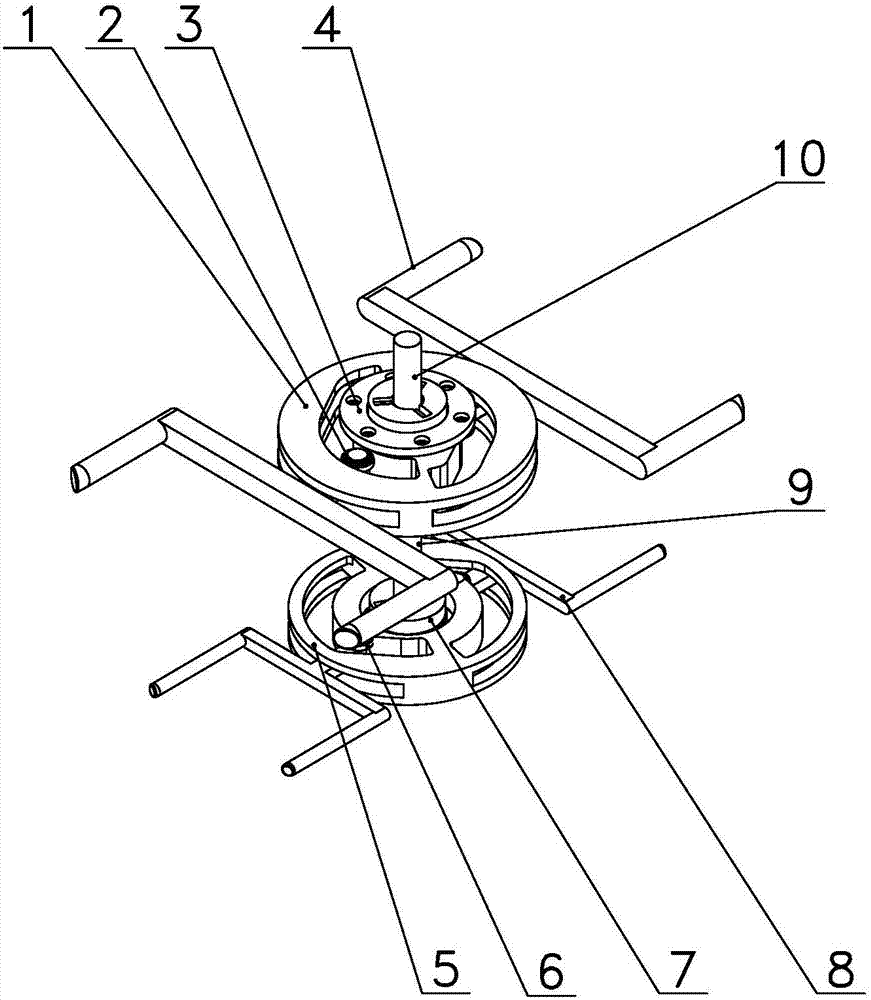

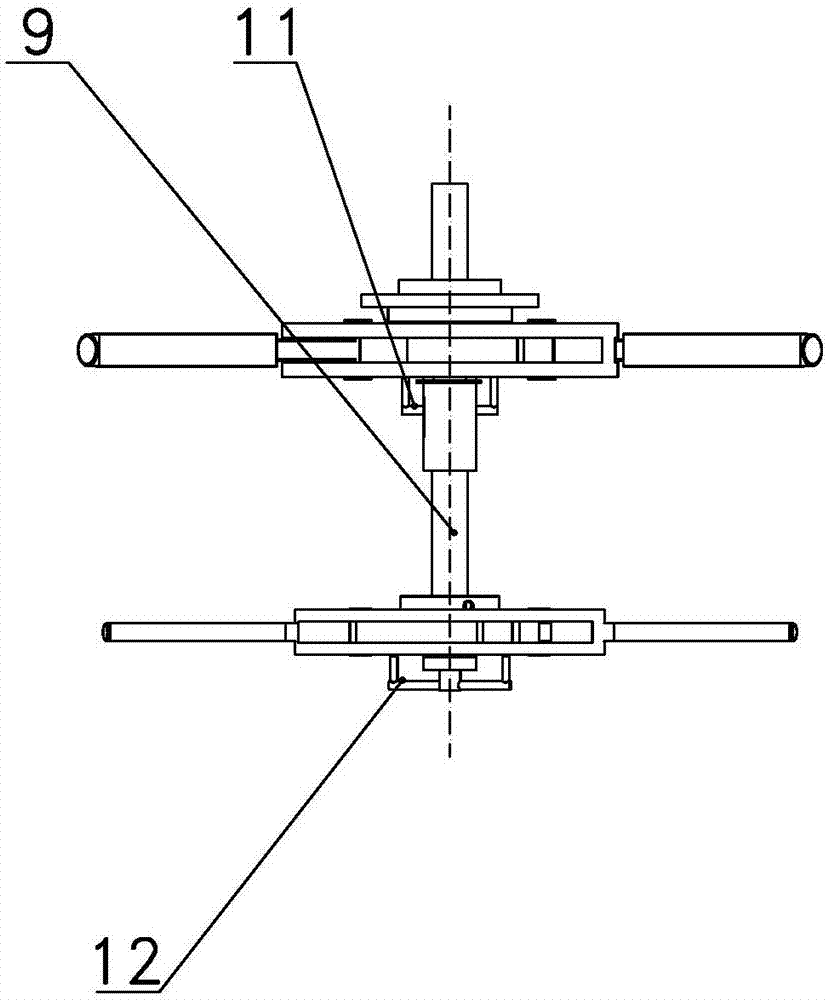

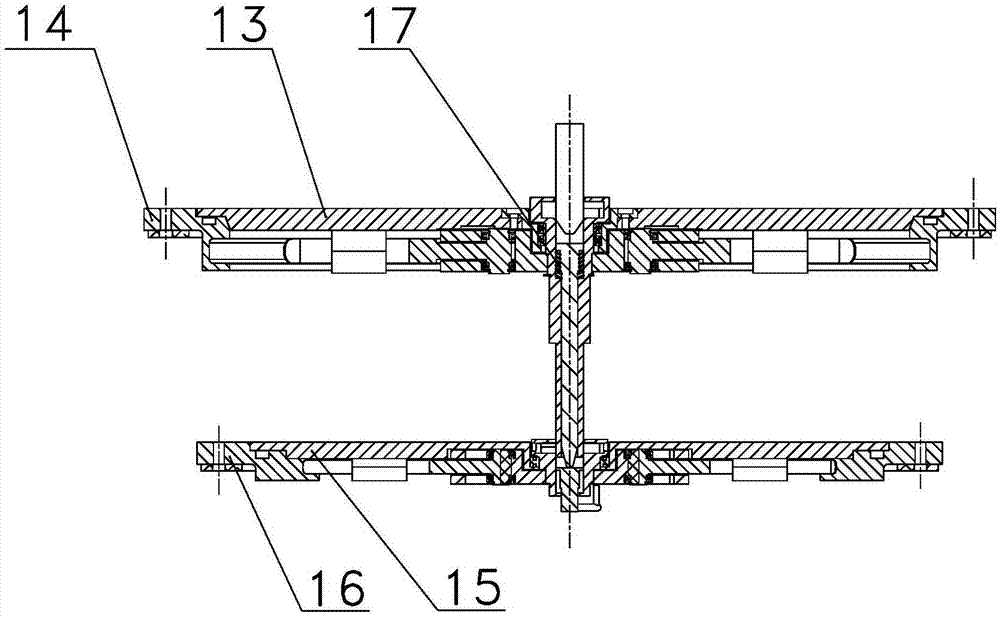

[0023] Taking the double-lid sealing device as an example below, the double-lid sealing device includes an outer lid sealing device, an inner lid sealing device, and may further include a self-locking device. Such as figure 1 As shown, the outer lid sealing device includes an outer lid turntable 1, and the outer lid turntable 1 is provided with multiple grooves with different shapes (see Figure 4 ), the outer cover bearing 2 is arranged in the groove of the outer cover turntable 1, the inner side of the groove is the outer cover support 3, the outer cover 13 is fixedly connected with the outer cover support 3, and the outer cover bearing 3 is connected to the outer cover The tie rod 4 is provided with a circular arc groove adapted to the end of the outer tie rod 4 on the outer cover flange 14 fixedly connected with the barrel body (see image 3 ). The inner lid sealing device includes an inner lid turntable 5, and the inner lid turntable 5 is provided with a plurality of grooves w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap