Liquid fuel combustion device and combustion system

A liquid fuel and combustion device technology, which is applied to the combustion of liquid fuel and gaseous fuel, the combustion of multiple fuels, the combustion of block fuel and gaseous fuel, etc., and can solve the problem of large liquid fuel particles and small specific surface area, etc. problem, to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

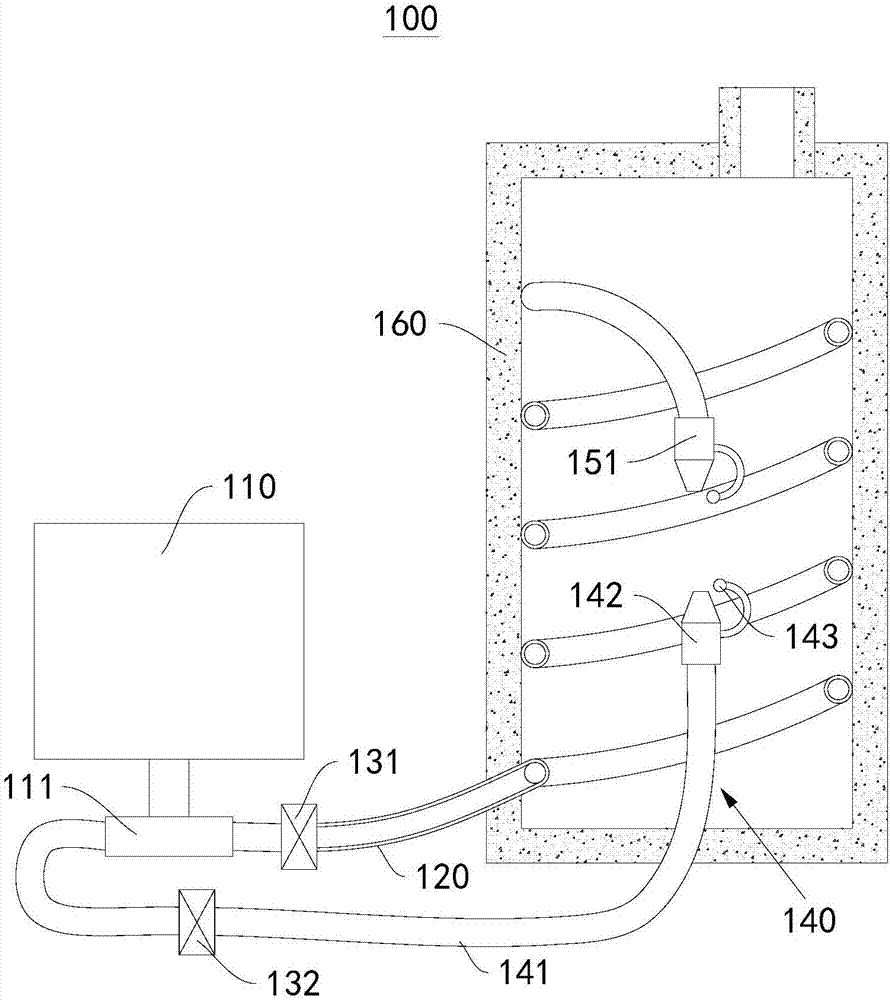

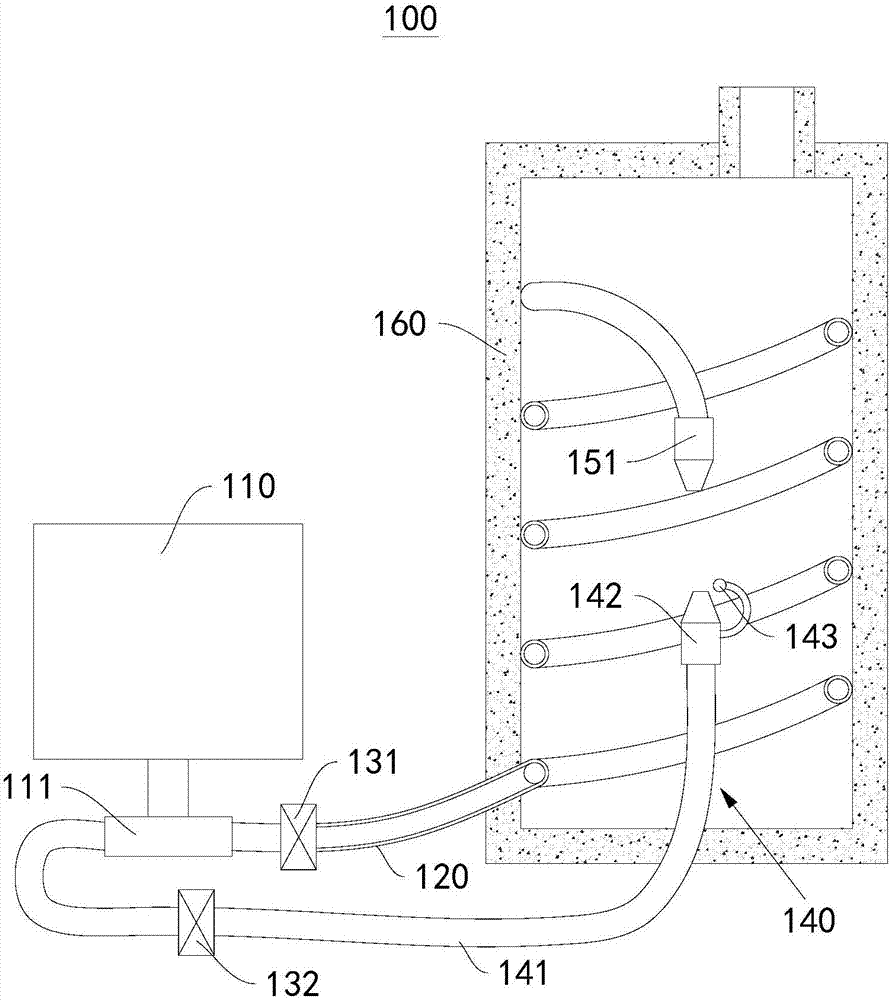

[0036] This embodiment provides a liquid fuel combustion device 100, please refer to figure 1 , figure 2 , image 3 as well as Figure 4 , this liquid fuel combustion device 100 includes:

[0037] combustion chamber 160;

[0038] The first pipeline 120, the first pipeline 120 is at least partly located inside the combustion chamber 160, and the first nozzle 151 is connected to one end of the first pipeline 120 located inside the combustion chamber 160;

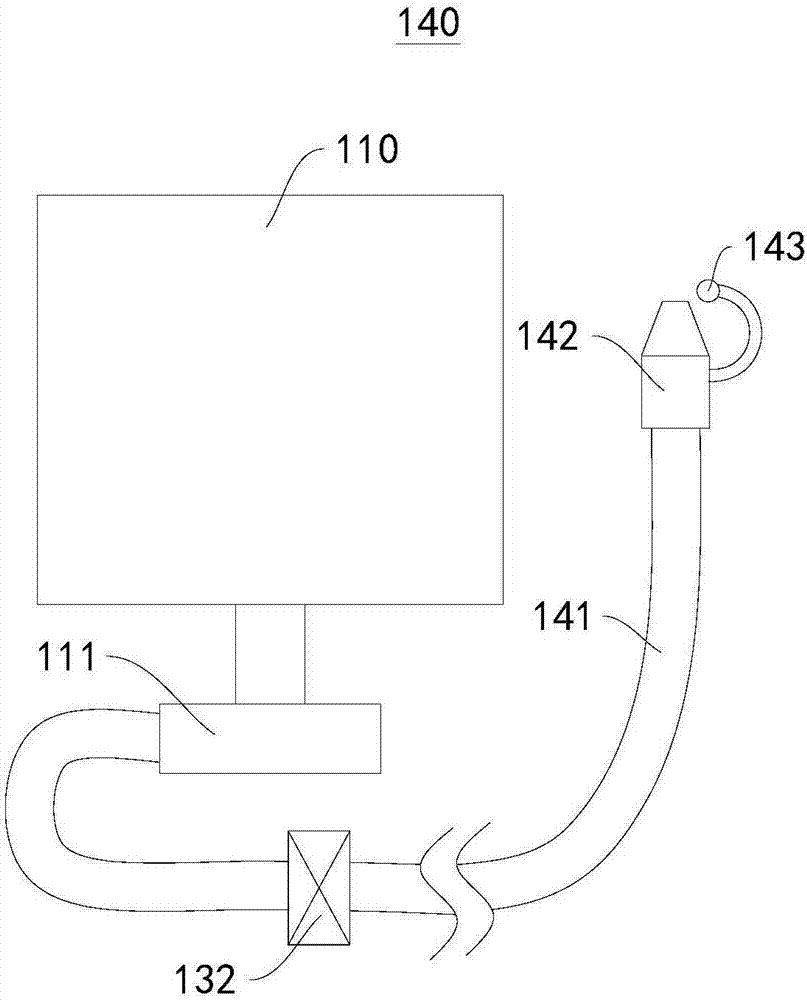

[0039] A heating mechanism 140, the heating mechanism 140 is connected to the combustion chamber 160, and the heating mechanism 140 is used to heat the combustion chamber 160;

[0040] The fuel supply mechanism 110 , the fuel supply mechanism 110 communicates with the first pipeline 120 , and the fuel supply mechanism 110 is used to deliver liquid fuel to the first pipeline 120 .

[0041] In the inside of the combustion chamber 160, at first realize the heating to the combustion chamber 160 by the heating mechanism 140, bec

Embodiment 2

[0071] This embodiment provides a combustion system, which includes the liquid fuel combustion device 100 provided in Embodiment 1.

[0072] Optionally, this combustion system also includes a solid fuel combustion device for burning solid fuel and a gaseous fuel combustion device for burning gaseous fuel, wherein the liquid fuel combustion device 100 is the liquid fuel combustion device 100 provided in Embodiment 1.

[0073] The working principle of the combustion system provided in this embodiment is that, during operation, the liquid fuel combustion device 100 can be used to achieve full combustion of liquid fuel, improve the utilization rate of liquid fuel, and thus improve the utilization of fuel in the entire combustion system Rate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap