Carbon fiber composite material enhanced ultrahigh pressure movable bend

A technology of composite materials and swivel elbows, applied in the direction of elbows, pipes/pipe joints/fittings, siphons, etc., can solve the problems of short service life of elbows, inconvenient installation and transportation, and bulky elbows, etc., to achieve Improve the safety of use, good operability, increase the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

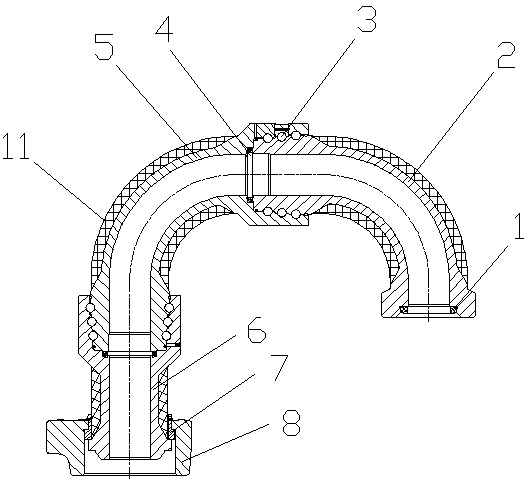

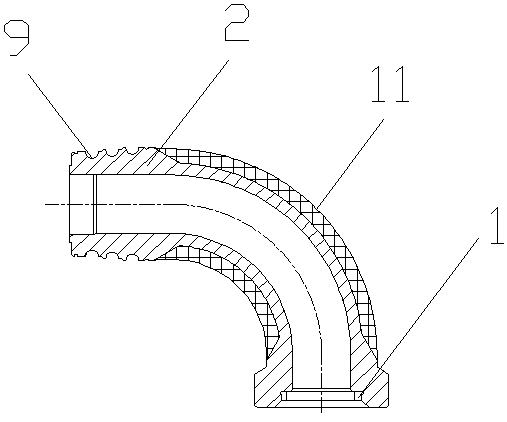

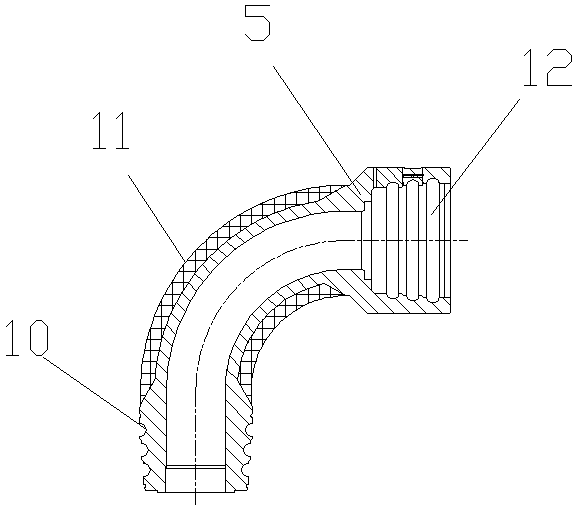

[0023] See attached Figure 1-4

[0024] 1. Elbow processing: First, AD elbow 2, AB elbow 5 and BC straight head 6 are processed and formed according to the basic shape of the metal, including the union joints at both ends of each elbow, AD elbow 2, and AB elbow 5 The upper steel ball groove 9 and the lower steel ball groove 10, the inner ball track 12 of the AB elbow 5 and the BC straight head 6, and the stopper at the end of the BC straight head 6. Then, according to the set process, the carbon fiber composite material 11 is respectively inlaid on the outer surface of the AD elbow 2, the AB elbow 5 and the BC straight end 6. The number of coating layers and the process need to be specially designed. To determine the required reinforcement effect and product structure, the outer layer of the carbon fiber composite mater

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap