X-ray monitored steel wire rope core conveyor belt joint tensile test method

A technology of steel wire rope core and experimental method, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problems of weakness, low tensile strength, safety hazard, safety production threat, etc., to improve accuracy The effect of improving data accuracy and good use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the content of the invention will be described below in conjunction with the accompanying drawings.

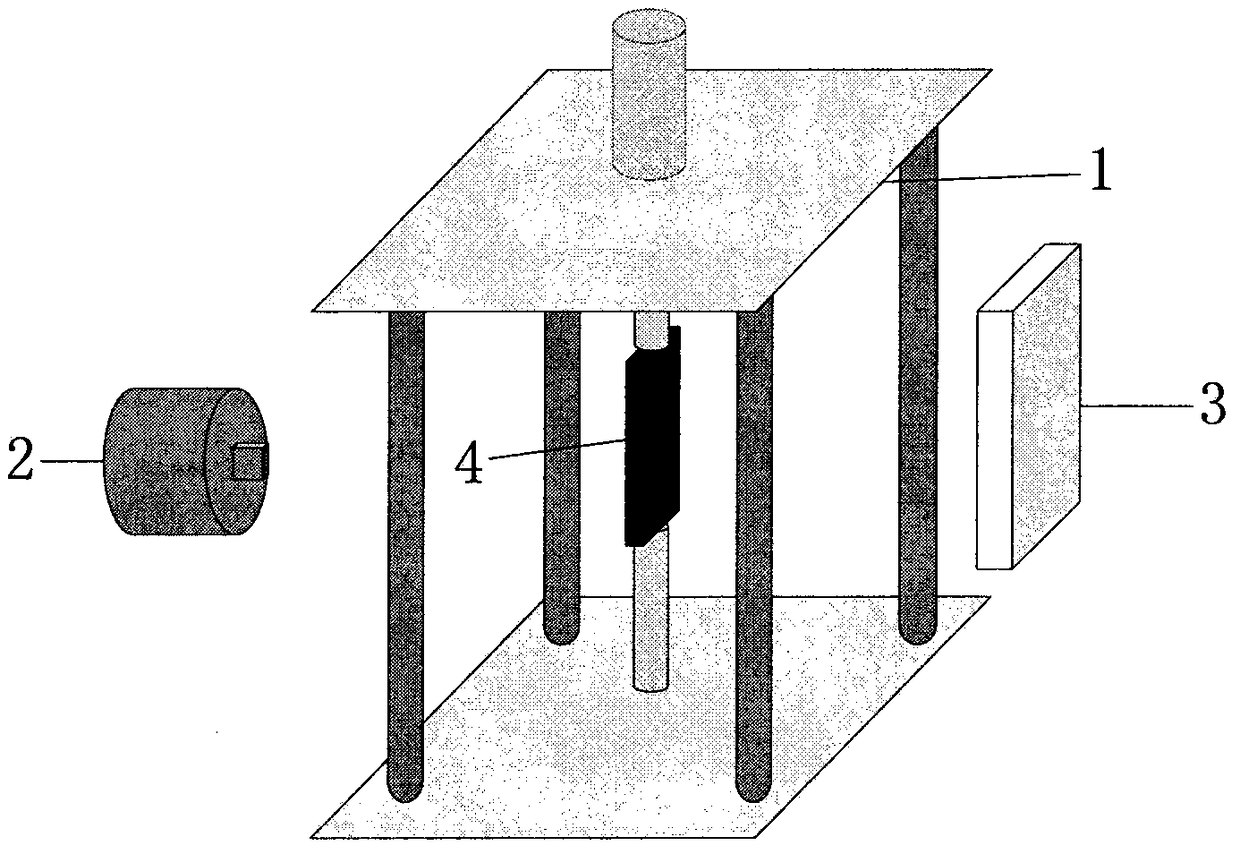

[0018] Such as figure 1 As shown, the hardware device of the tensile test in the present invention is composed of a tensile testing machine 1 , an X-ray source 2 , an X-ray dynamic flat panel detector 3 and a joint sample 4 . The joint sample is fixed in the tensile testing device of the tensile testing machine 1, and the X-ray source 2 and the X-ray dynamic flat panel detector 3 are respectively installed on both sides of the surface area of the joint sample, so that the X-ray source 2 can project On the surface of the joint sample 4, the X-ray dynamic flat panel detector 3 can collect the steel wire rope core image inside the joint sample 4. The X-ray dynamic flat panel detector 3 selects an area array dynamic imaging detector with a resolution of 1316×1312 and an imaging speed of not less than 10 frames per second to obtain high-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap