Fixed-length cutting device for PVC plastic floor

A cutting device and technology for plastic flooring, which is applied in metal processing and other directions, can solve the problems of large impact force of PVC plastic flooring and damage to the internal structure of PVC plastic flooring, and achieve the effects of avoiding damage, improving processing accuracy, and improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

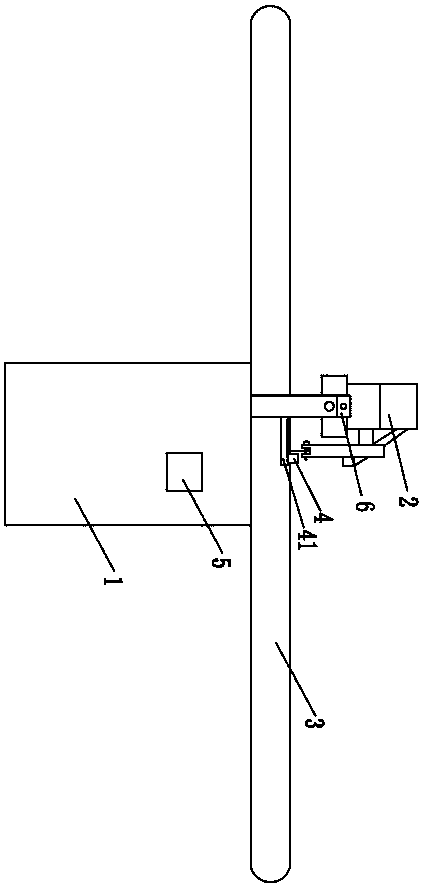

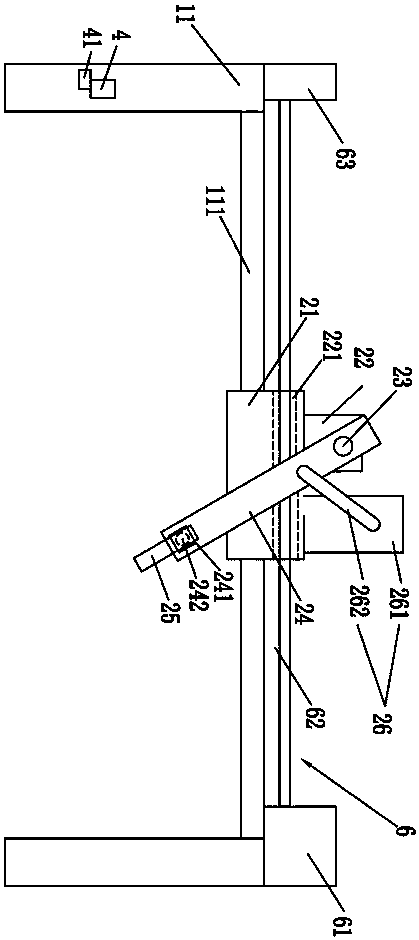

[0019] Such as Figure 1-2 As shown, a fixed-length cutting device for PVC plastic floor includes a base 1 and a cutting mechanism 2 for cutting the floor. It also includes a conveying mechanism 3 for conveying the floor, an infrared sensor 4, and a PLC controller 5. The conveying mechanism 3 It is rotatably mounted on the base 1, the cutting mechanism 2 is mounted on the base 1 and above the conveying mechanism 3. The infrared sensor 4 is mounted on the cutting mechanism 2 through the sensor bracket 41, the infrared The sensor 4 is installed in front of the cutting end of the cutting mechanism 2, the PLC controller 5 is installed on the base 1, and the conveying mechanism 3 and the infrared sensor 4 are connected to the PLC controller 5.

[0020] Further, the cutting mechanism 2 is installed on the base 1 through a support frame 11, and the support frame 11 is provided with a horizontally arranged sliding shaft 111 whose axis is perpendicular to the conveying direction of the conve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap