Apparatus used for hydrogen production through reforming of methanol-water

A technology for reforming hydrogen production and methanol water, applied in hydrogen, hydrogen/synthesis gas production, inorganic chemistry, etc., can solve the problems of increasing equipment cost, aging of heating gasification pipeline, affecting user experience, etc., and achieves high conversion rate , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

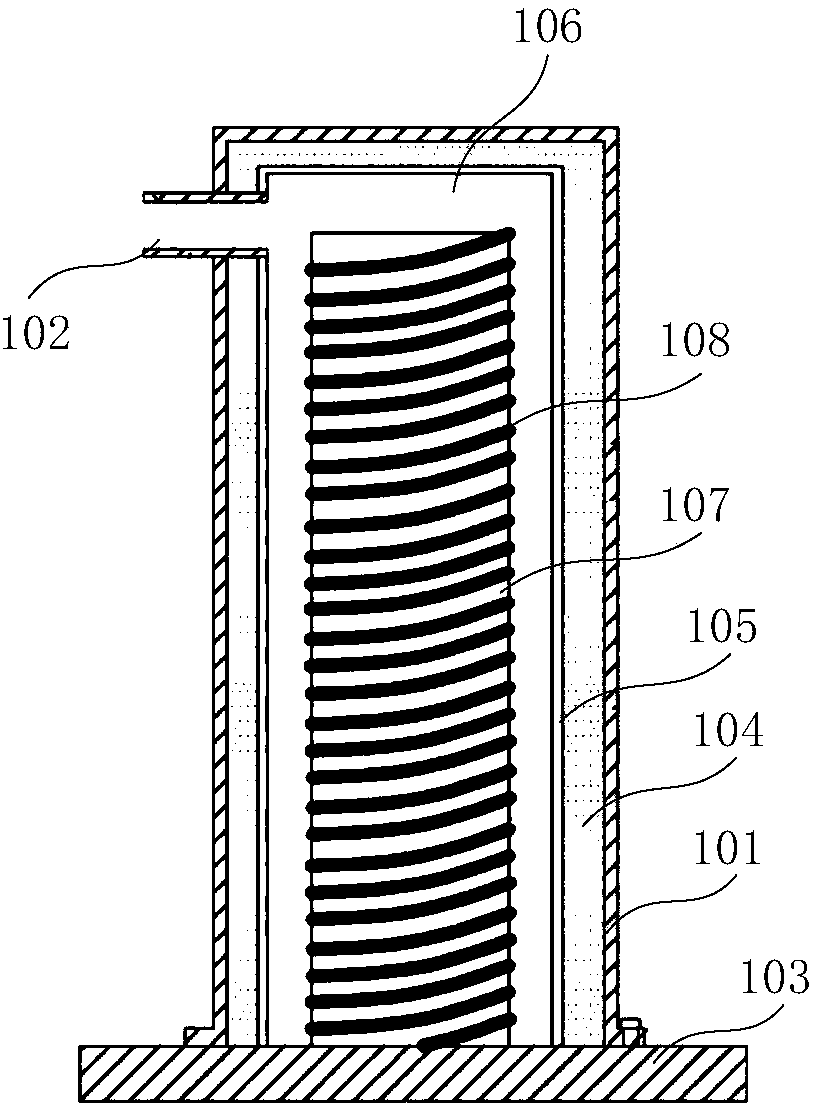

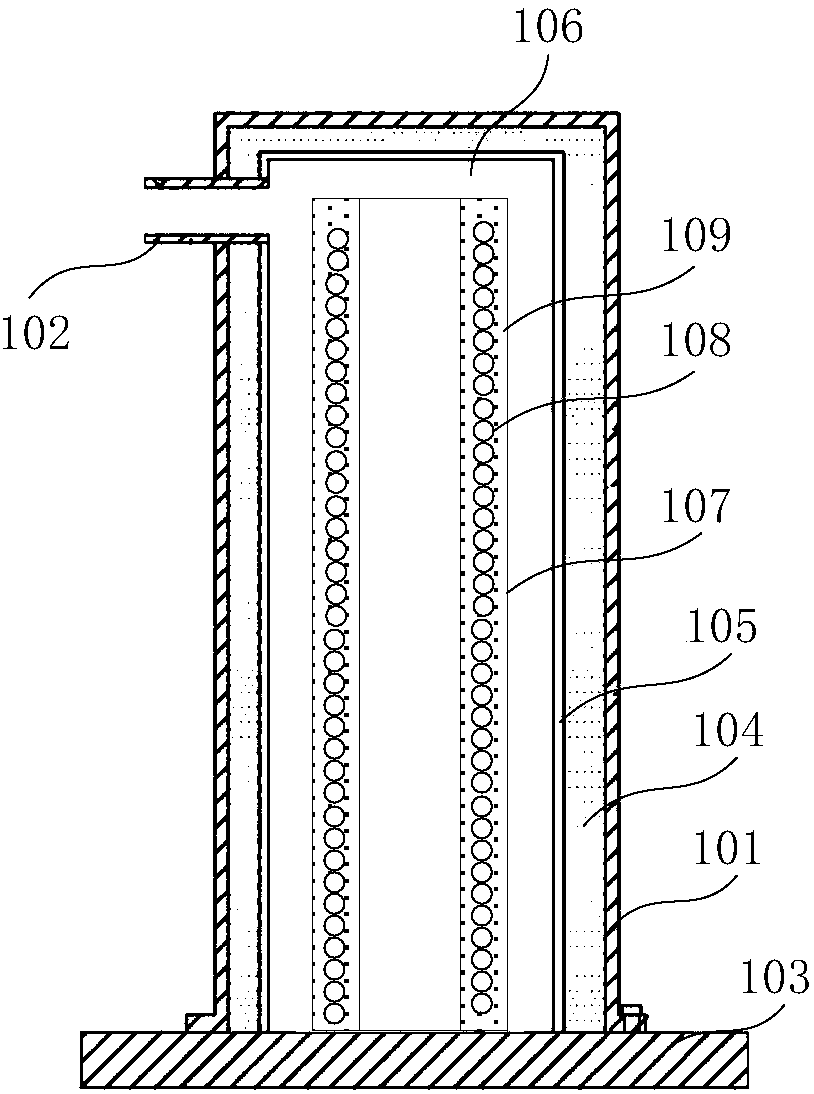

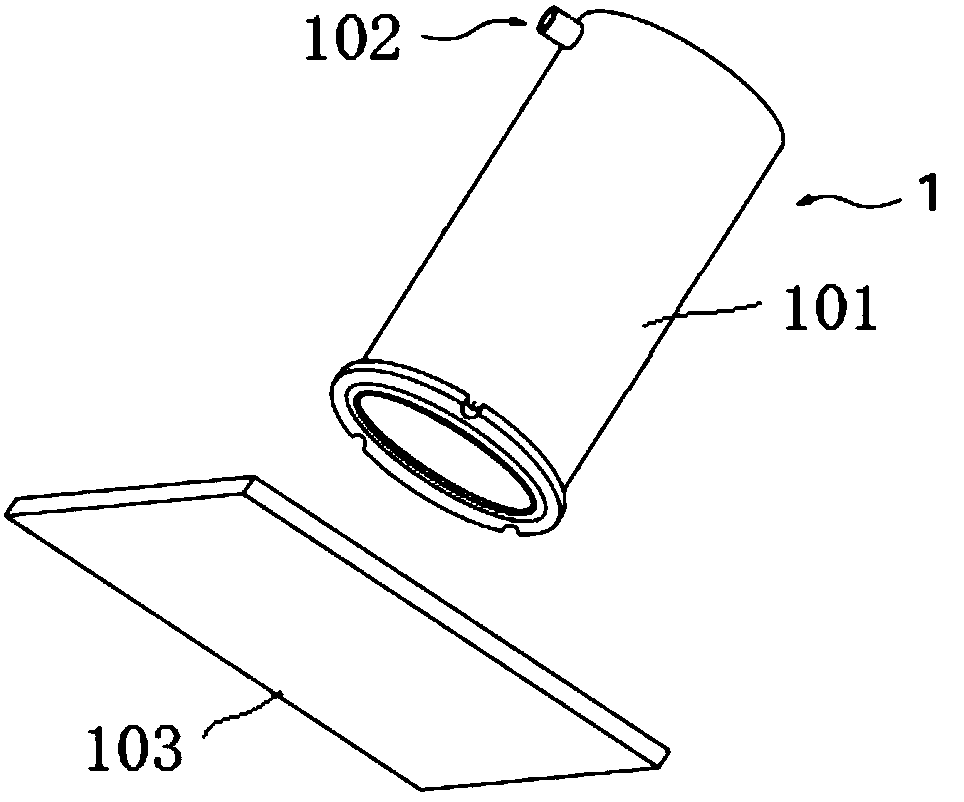

[0028] see Figure 4 , the present invention discloses a methanol water reforming hydrogen production equipment, the methanol water reforming hydrogen production equipment 1 includes a raw material delivery device 11, a methanol water delivery pipeline 12, a reforming unit 13, a separation unit 14, and a hydrogen delivery pipe Road 15, residual gas discharge pipeline 17, starting device 18, control circuit board 19. The raw material delivery device 11 is connected to the storage container 2 , and transports the raw material in the storage container 2 to the reformer 13 through the methanol water delivery pipeline 12 .

[0029] The basic composition of methanol water reforming hydrogen production equipment can be basically realized by those skilled in the art according to the relevant patents of the applicant (such as the introduction of several existing hydrogen production equipment in the background technology section, in addition, you can also refer to three Authorized inventi

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that in this embodiment, the methanol-water reforming hydrogen production equipment also includes a hydrogen buffer storage container; the hydrogen buffer storage container is used to store the Part of the hydrogen is prepared for subsequent hydrogen power generation equipment to generate electricity.

[0039] The methanol water reforming hydrogen production equipment also includes a hydrogen buffer storage container, which is respectively connected to the separation device and the hydrogen fuel cell; the hydrogen buffer storage container is used to store the part generated by the methanol water reforming hydrogen production equipment Hydrogen, in preparation for hydrogen fuel cell power generation. The hydrogen buffer storage container is provided with a buffer container controller, a hydrogen pressure sensor, an inlet solenoid valve, and an exhaust outlet solenoid valve. The hydrogen pressure sensor is used to se

Embodiment 3

[0042] 【Voice control method】

[0043] see Image 6 The difference between this embodiment and Embodiment 1 is that in this embodiment, the methanol-water reforming hydrogen production equipment also includes a voice database, a voice acquisition module, a voice recognition module, a voice command execution module, a voice self-learning module, a voice Database update module; the voice database is used to store voice data, and execution commands corresponding to each voice data; the voice acquisition module is used to acquire voice data; the voice recognition module is used to combine the acquired voice data with the voice data in the voice database The voice data is compared, if there is consistent voice data in the voice database, the comparison result is fed back to the voice command execution module; the voice command execution module is used to execute the corresponding command according to the recognition result of the voice recognition module; The speech self-learning mod

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap