Train carriage connecting mechanism based on universal joint

A connecting mechanism and universal joint technology, applied in railway car body parts, railway vehicle coupling accessories, railway couplings, etc., can solve the problems of vibration, coupler friction damage, and high coupler, and reduce rigidity Interference and friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

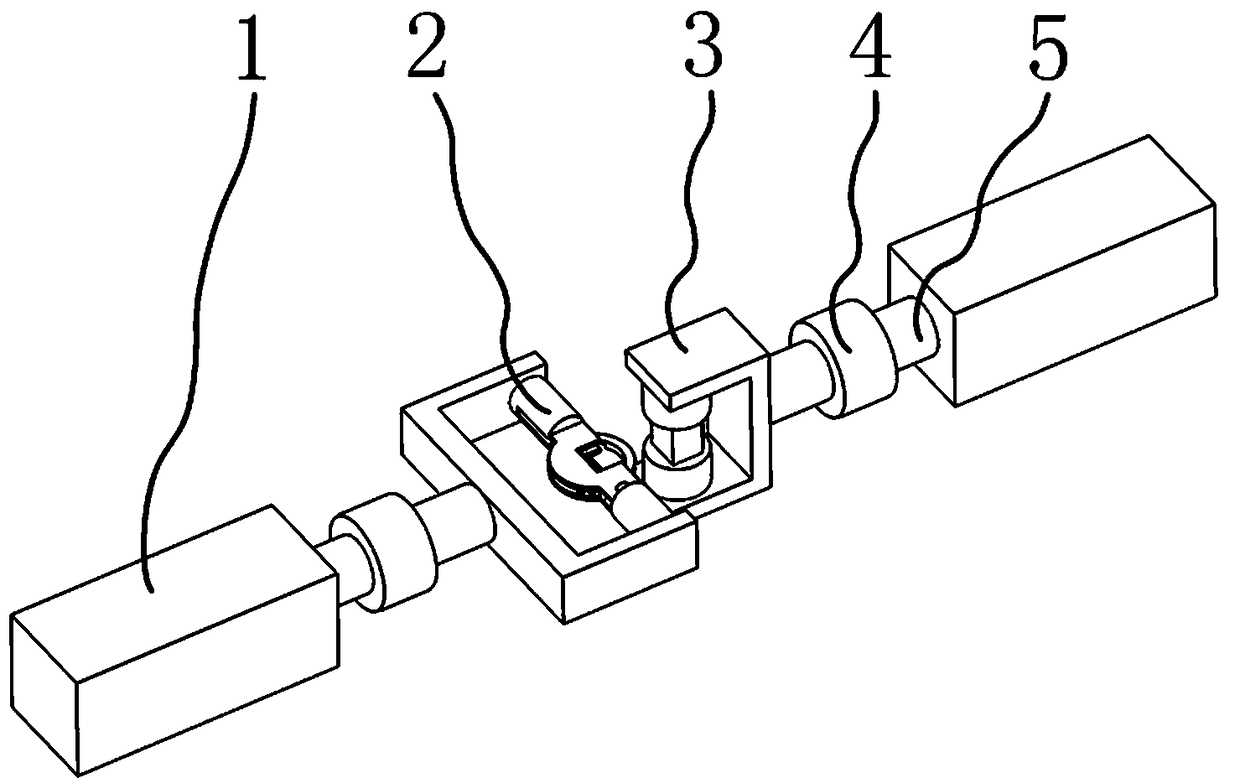

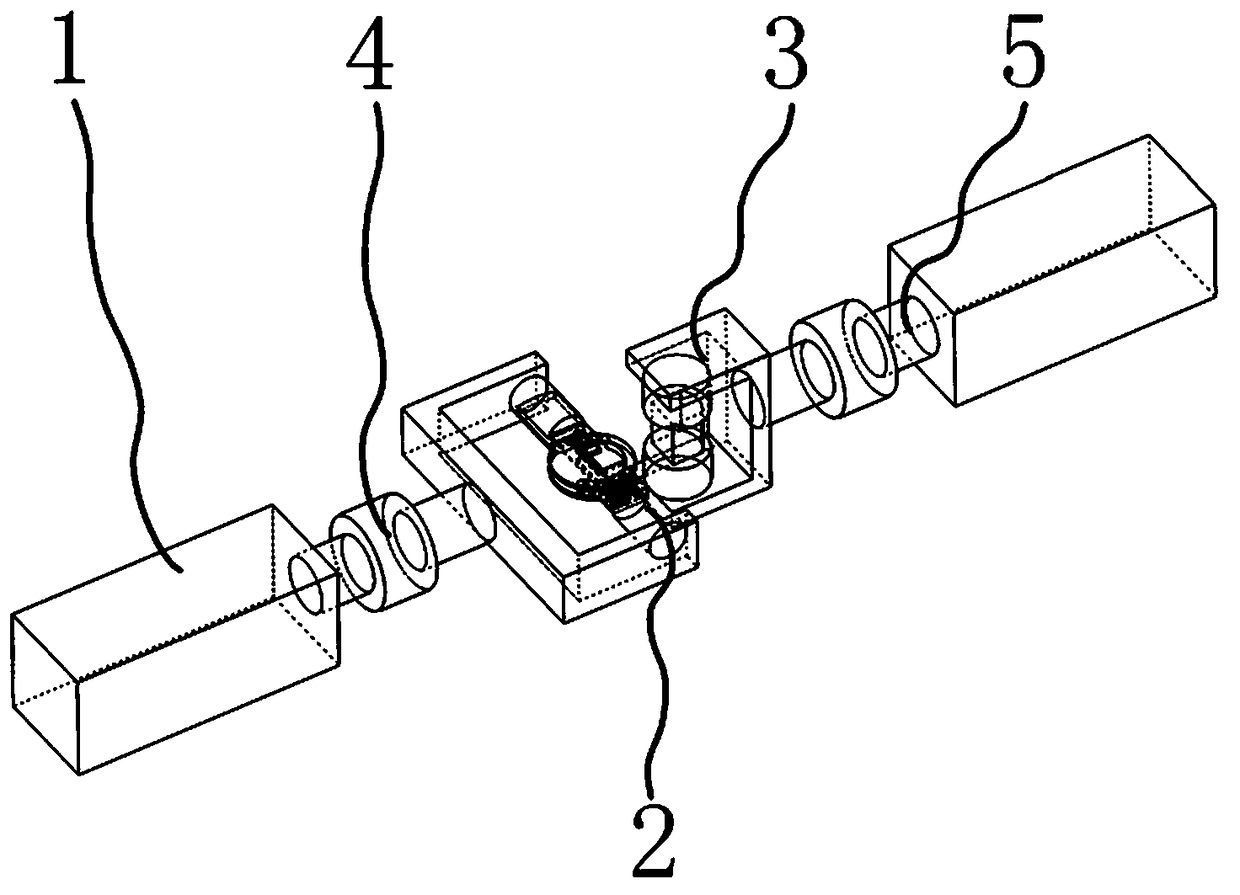

Image

Examples

specific Embodiment approach

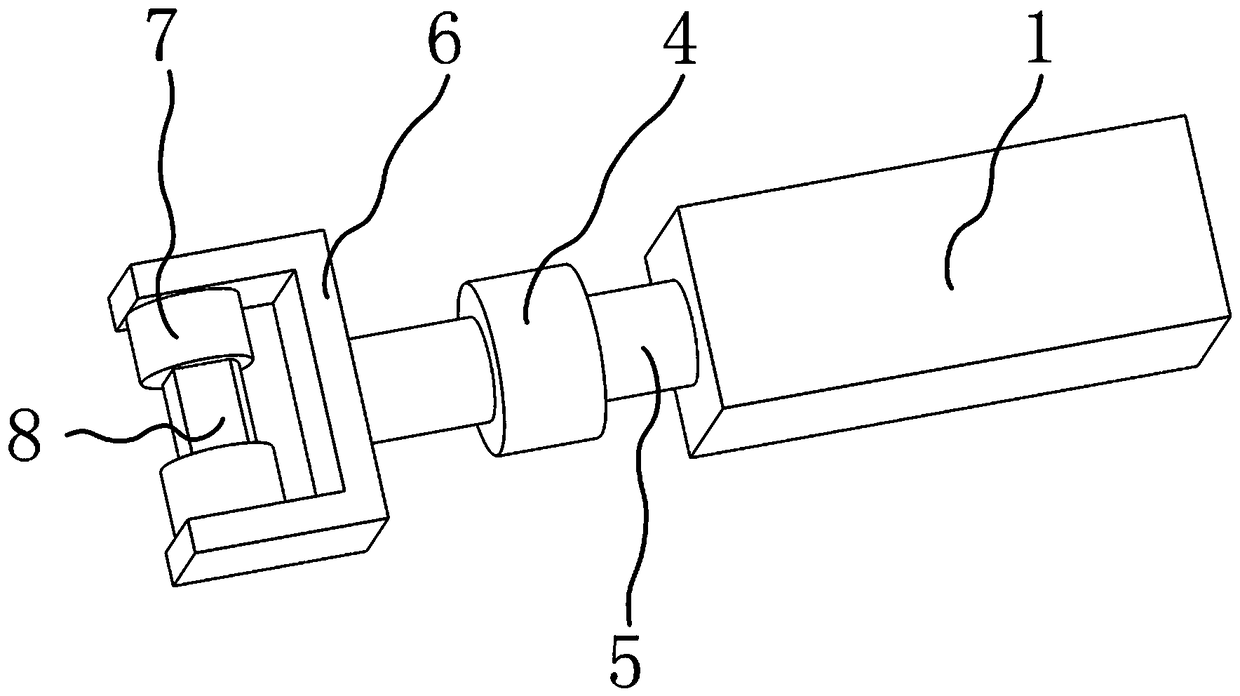

[0056] DETAILED DESCRIPTION: When the train car connecting mechanism designed by the present invention is used, in the process of connecting two cars; the rear car is controlled so that the rear car moves to the corresponding front car; the movement of the rear car will cause the limit semicircle 14 It rotates around the fixed shaft 34; when the limit semicircular ring 14 rotates to contact with the trigger tooth 36 installed on the trigger block 35, the trigger tooth 36 on the limit semicircular ring 14 will squeeze the corresponding limit Position teeth 30; make the limit teeth 30 move into the corresponding limit groove 31; when the limit semicircular ring 14 is completely moved to coincide with the arc surface 9 on the first connecting block 8, the scroll spring 44 Completely released; at this time, the limiting semicircular ring 14 stops rotating; the limiting semicircular ring 14 is in a static state under the action of the corresponding limiting tooth 30; that is, the two ad

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap