Mine cable laying device

A cable laying and mining technology, applied in the direction of cable laying equipment, etc., can solve the problems of unfavorable and fast installation, low safety factor, high labor intensity, etc., and achieve the effect of convenient operation, low cost, and reduced labor intensity of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the structural features and functional features of the present invention easier to understand, the present invention will be further explained below in conjunction with the embodiments and accompanying drawings.

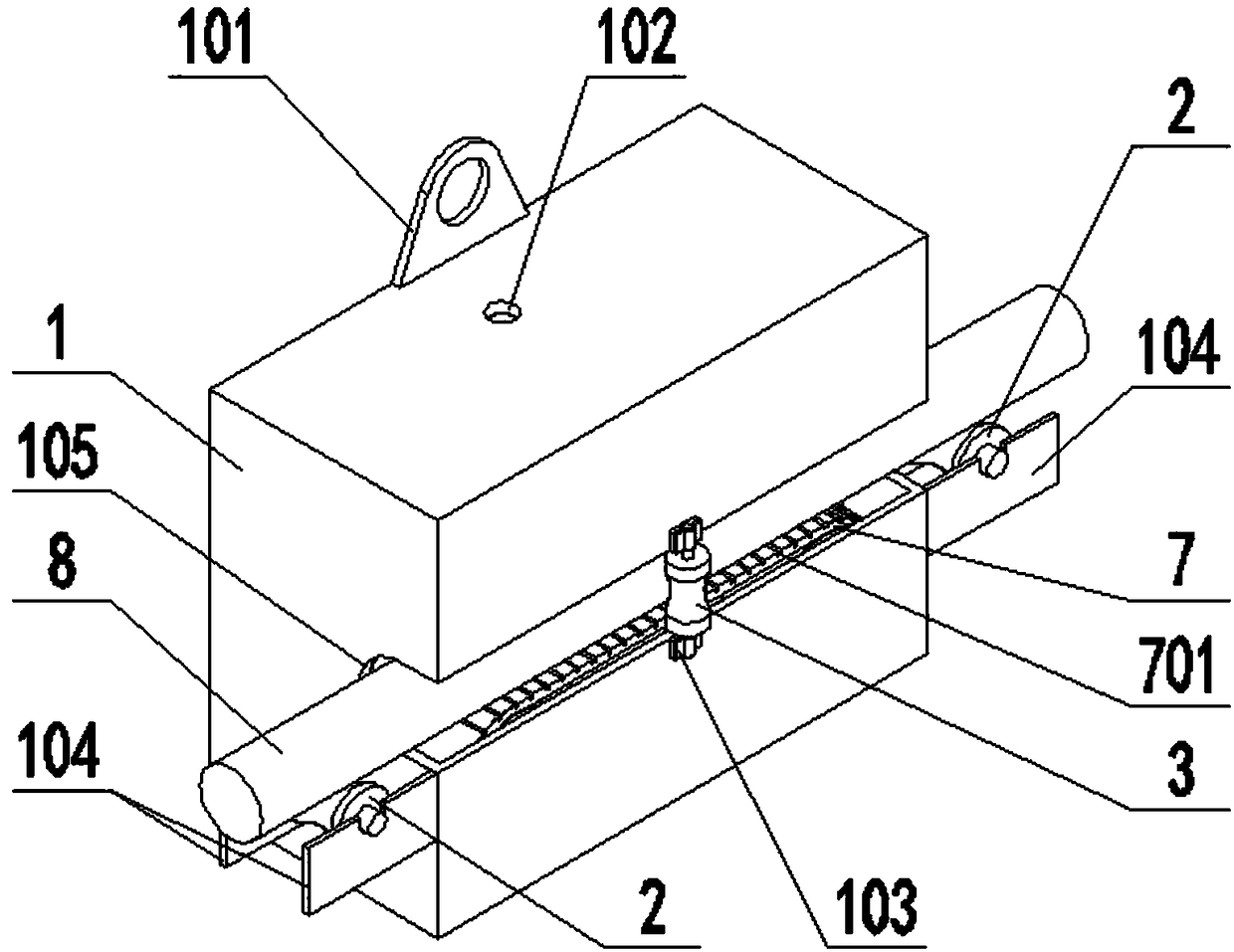

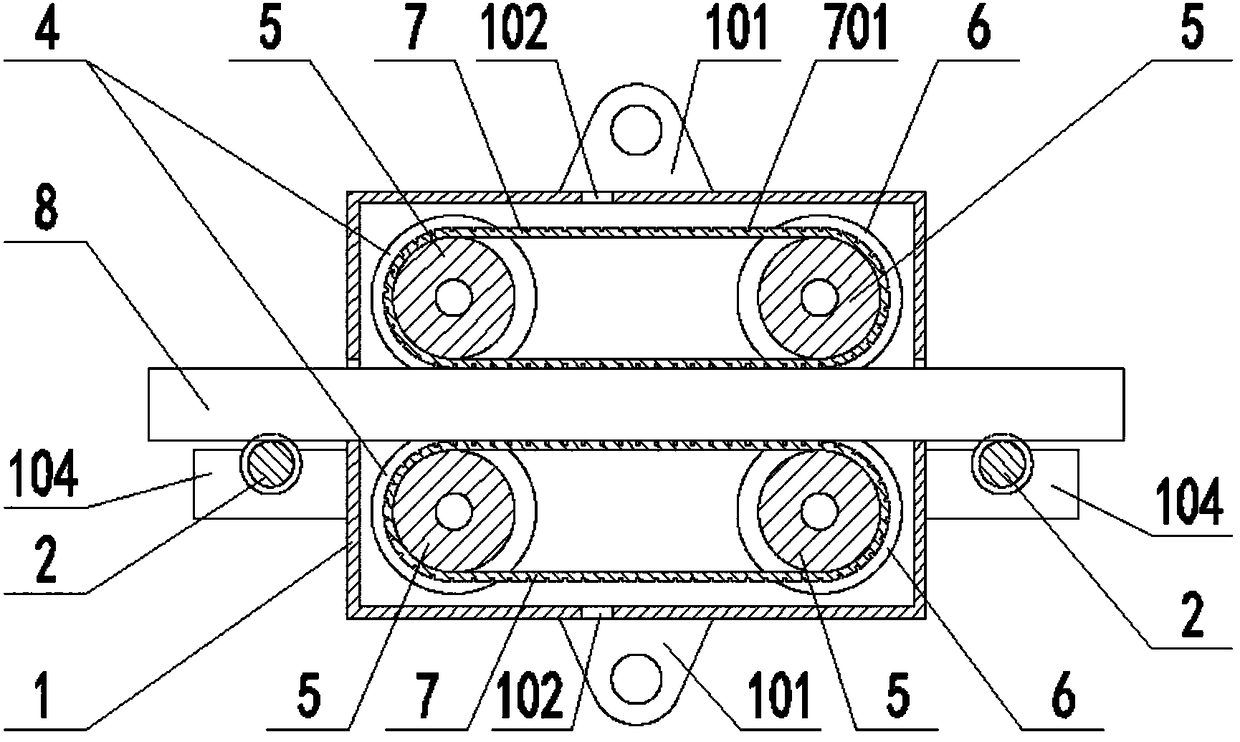

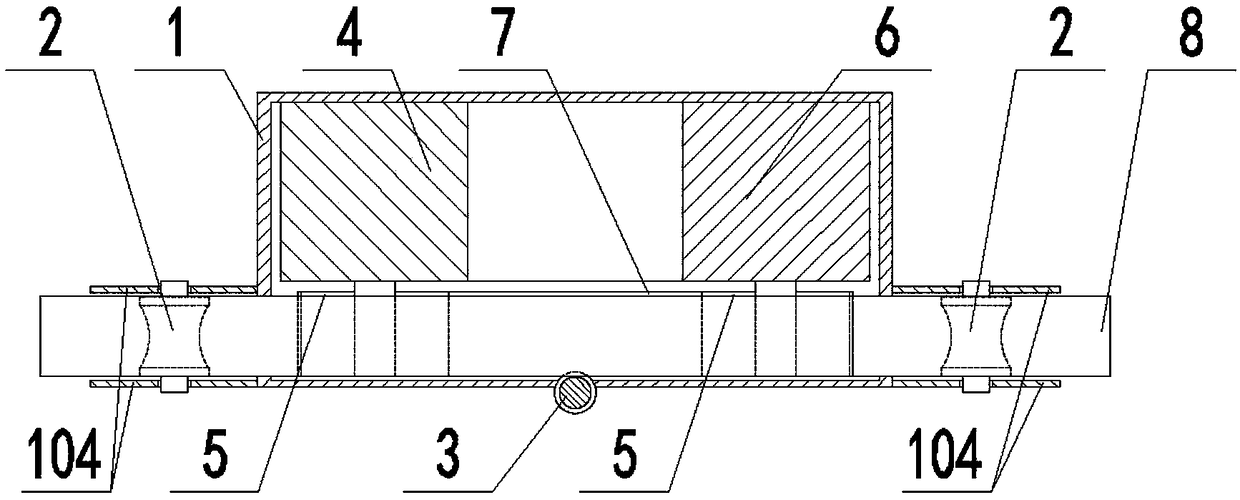

[0015] Such as Figure 1 ~ Figure 3 As shown, a mining cable laying device provided by the present invention includes a casing 1, idler roller I2, idler roller II3, air motor 4, pulley 5, support seat 6, and belt 7. The upper part of the casing 1 A hanging ear 101 and a through hole 102 are provided on the side and the lower side, a fixing seat 103 and a U-shaped groove 105 are provided on the front side of the housing 1, and two The bracket 104 is provided with a pulley 5 on the front side of the air motor 4 , and a groove 701 is provided on the belt 7 .

[0016] Preferably, idler rollers I2 are provided on the brackets 104 on the left and right sides of the housing 1 .

[0017] Preferably, an idler roller II3 is provided on the fixed seat ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap