Numerical-control processing device

A technology for control modules and electrical control cabinets, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as inconvenient disassembly, and achieve the effect of improving flexibility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

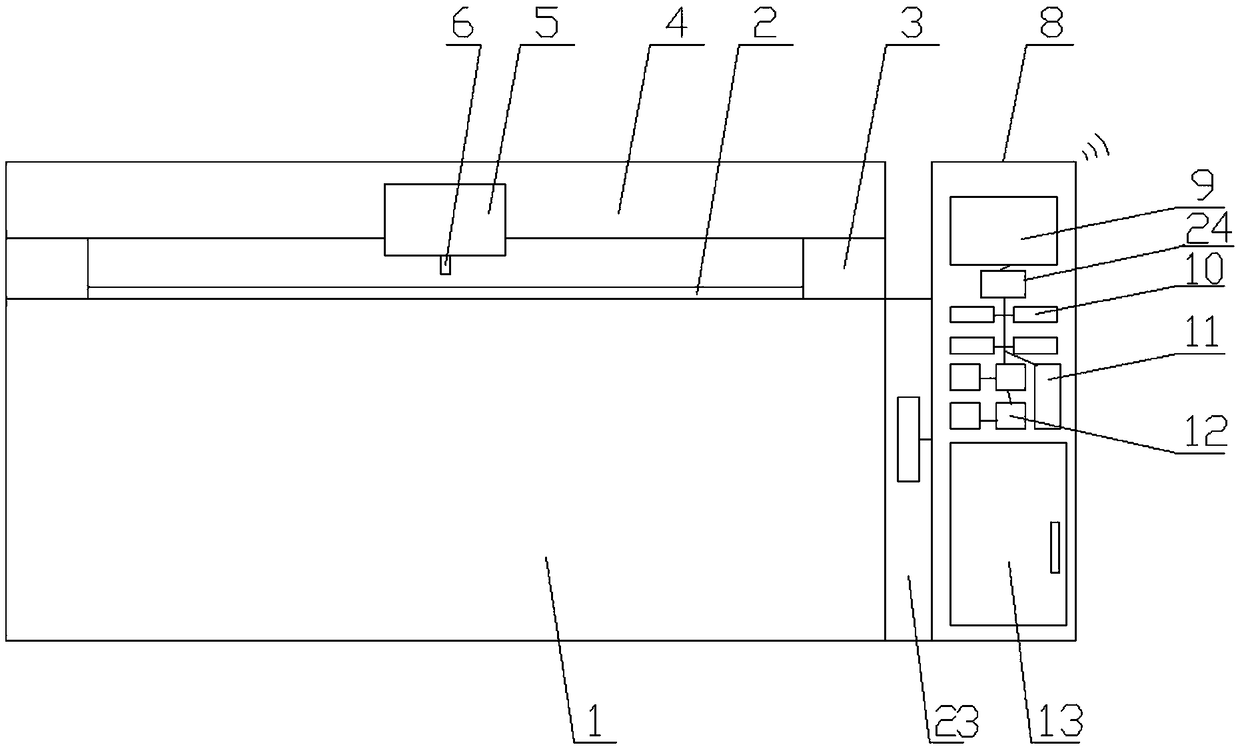

[0016] A kind of numerical control machining production device of the present invention, as figure 1 As shown, including a machine tool 1, the machine tool 1 is connected to the electrical control cabinet 8 through a connecting mechanism 23. Columns 3 are arranged at both ends of the machine tool 1, and a beam 4 is arranged above the column 3. Motor 5, the first motor 5 moves left and right on the crossbeam 4, the first motor 5 bottom transmission is connected with the drill bit 6, simultaneously controls the product to move by the conveyer belt 2, cooperates the first motor 5 to control the drill bit 6 to carry out drilling. A conveyor belt 2 is arranged under the beam 4, and the conveyor belt 2 is arranged between two columns, and a column 3 is arranged at both ends; a display screen 9 is arranged on the side wall of the electrical control cab

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap