Method for preparing expandable microspheres rapidly by soap-free emulsion polymerization under boiling condition

A technology for soap-free emulsion polymerization and expansion of microspheres, which is applied in the field of soap-free emulsion polymerization, can solve the problems of reducing the amount of emulsifier used, the influence of microsphere performance, and the long reaction time, and achieves increased efficiency, short reaction time, and rapid reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

[0025] 1. Refinement of monomers

[0026] The methacrylonitrile and methyl acrylate were washed three times with 10wt% sodium hydroxide aqueous solution to remove the polymerization inhibitor, then washed with distilled water until neutral, and the washed monomer was washed with anhydrous CaCl 2 After drying, set aside.

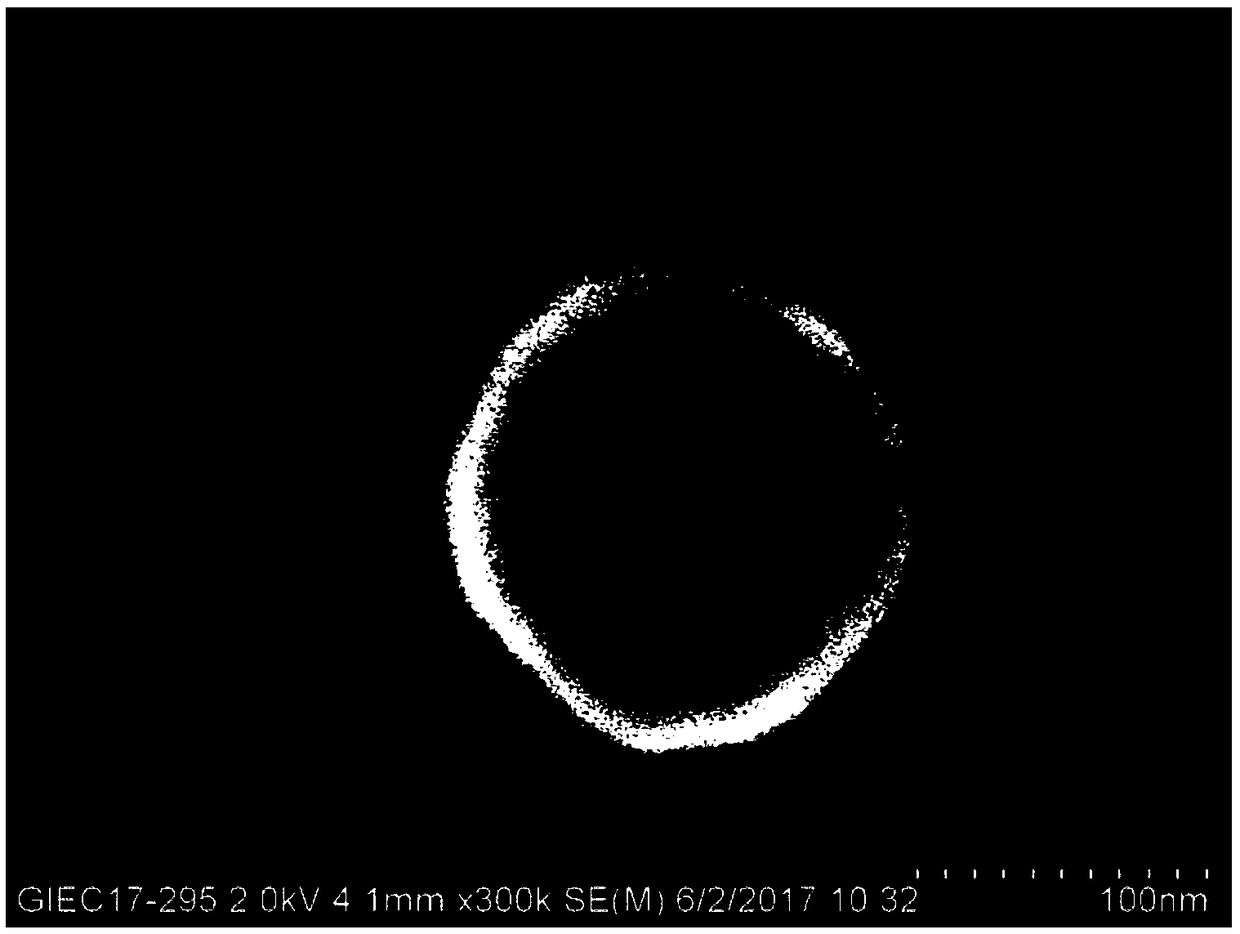

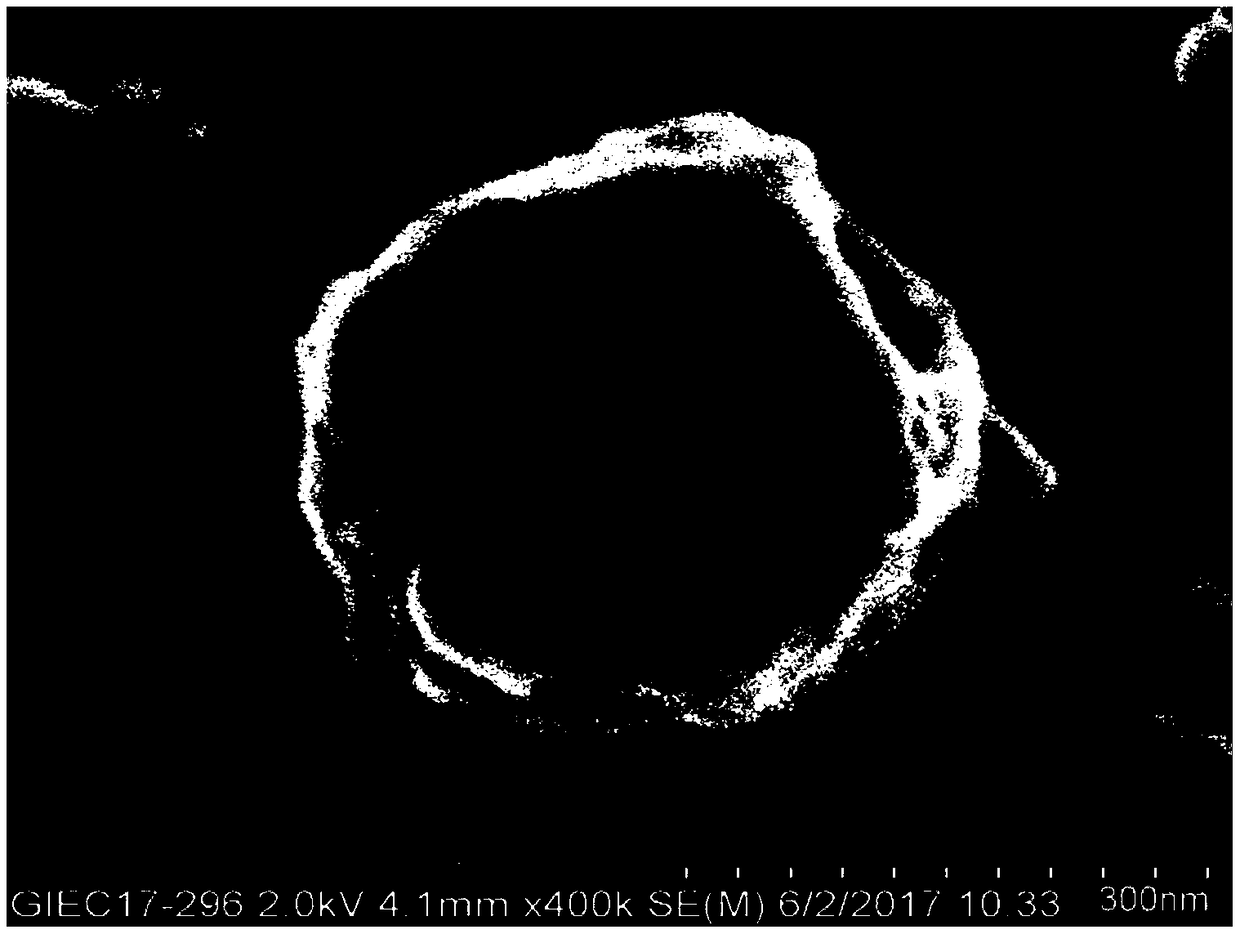

[0027] 2. Soap-free emulsion polymerization under boiling conditions

[0028] Mix 7 g of purified methacrylonitrile, 3 g of purified methyl acrylate, 4 g of n-octane, 0.02 g of divinyl benzene with 50 g of water for mass homogenization or ultrasonic treatment, heat up to boiling under stirring conditions, add 0.1g potassium persulfate is reacted for a period of time, the stirring speed is 200-2000r / min, the reaction temperature is 100°C, and the reaction time is 2-2.5h, to obtain a uniform and stable emulsion. Expandable microspheres were obtained under vacuum drying.

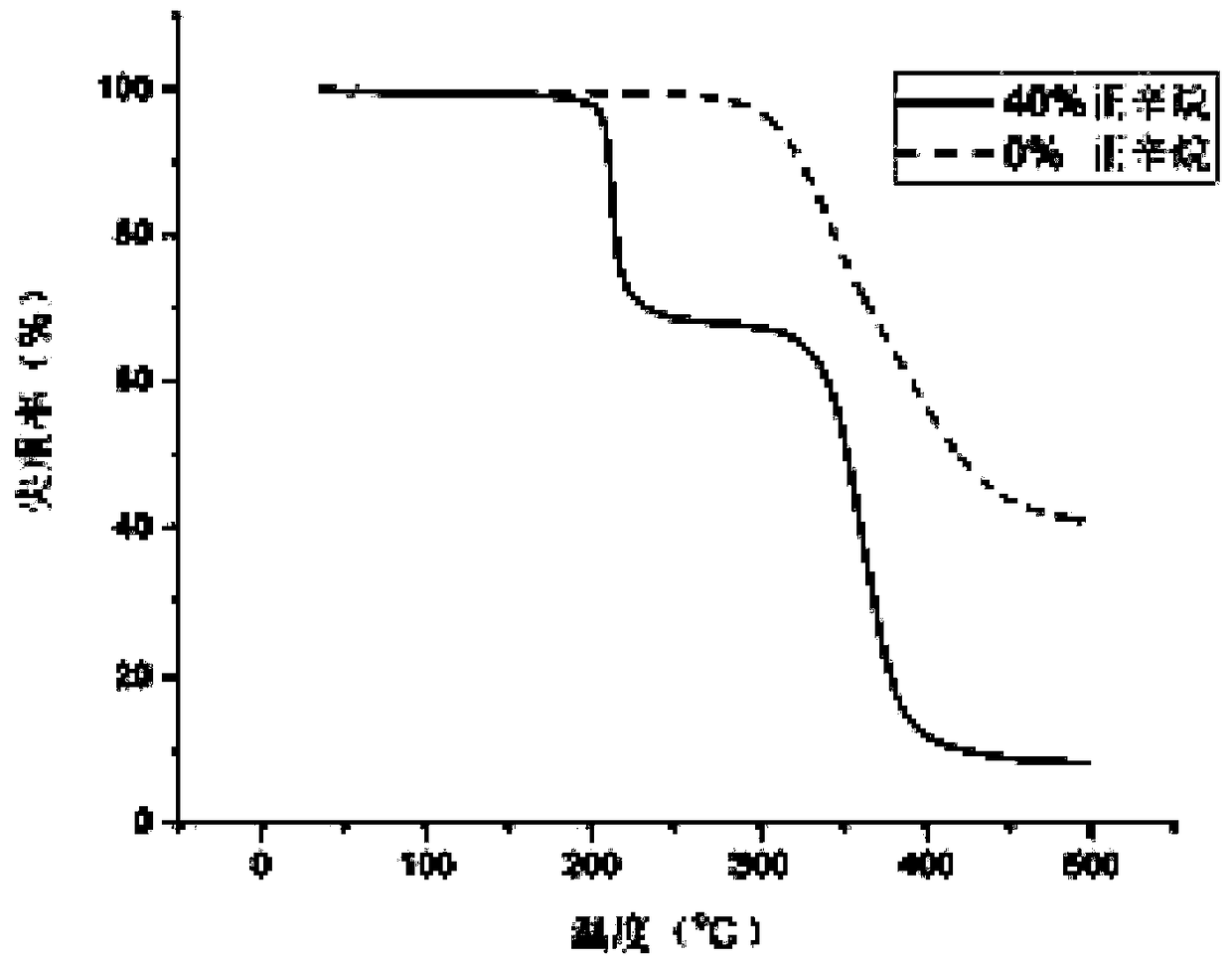

[0029] 3. Determination of Microsphere Swelling Properties

[0030]

Example Embodiment

[0034] Example 2

[0035] 1. Refinement of monomers

[0036] The methacrylonitrile and methyl acrylate were washed three times with 10wt% sodium hydroxide aqueous solution to remove the polymerization inhibitor, then washed with distilled water until neutral, and the washed monomer was washed with anhydrous CaCl 2 After drying, set aside.

[0037] 2. Soap-free emulsion polymerization under boiling conditions

[0038] Mix 7 g of purified methacrylonitrile, 3 g of purified methyl acrylate, 4 g of n-octane, 0.04 g of divinyl benzene with 50 g of water for mass homogenization or ultrasonic treatment, heat up to boiling under stirring conditions, add 0.1g potassium persulfate is reacted for a period of time, the stirring speed is 200-2000r / min, the reaction temperature is 100°C, and the reaction time is 2-2.5h, to obtain a uniform and stable emulsion. Expandable microspheres were obtained under vacuum drying.

[0039] 3. Determination of Microsphere Swelling Properties

[0040]

Example Embodiment

[0042] Example 3

[0043] 1. Refinement of monomers

[0044] The methacrylonitrile and methyl acrylate were washed three times with 10wt% sodium hydroxide aqueous solution to remove the polymerization inhibitor, then washed with distilled water until neutral, and the washed monomer was washed with anhydrous CaCl 2 After drying, set aside.

[0045] 2. Soap-free emulsion polymerization under boiling conditions

[0046] 7 g of purified methacrylonitrile, 3 g of purified methyl acrylate, 4 g of n-octane, 0.02 g of 1,4-butanediol dimethacrylate and 50 g of water were mixed for mass homogenization or ultrasonic treatment, and the mixture was stirred. The temperature is raised to boiling under the conditions of 100 °C, 0.1 g of potassium persulfate is added, and the reaction is carried out for a period of time. Expandable microspheres were obtained under vacuum drying.

[0047] 3. Determination of Microsphere Swelling Properties

[0048] The microspheres obtained above were placed in

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap