Numerical control shot-peening laser tool aligning device and method

A laser and shot peening technology, which is applied in metal processing equipment, used abrasive processing devices, manufacturing tools, etc., can solve problems such as nozzle inner diameter wear, affecting knife accuracy, etc., to improve knife setting accuracy and good linearity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

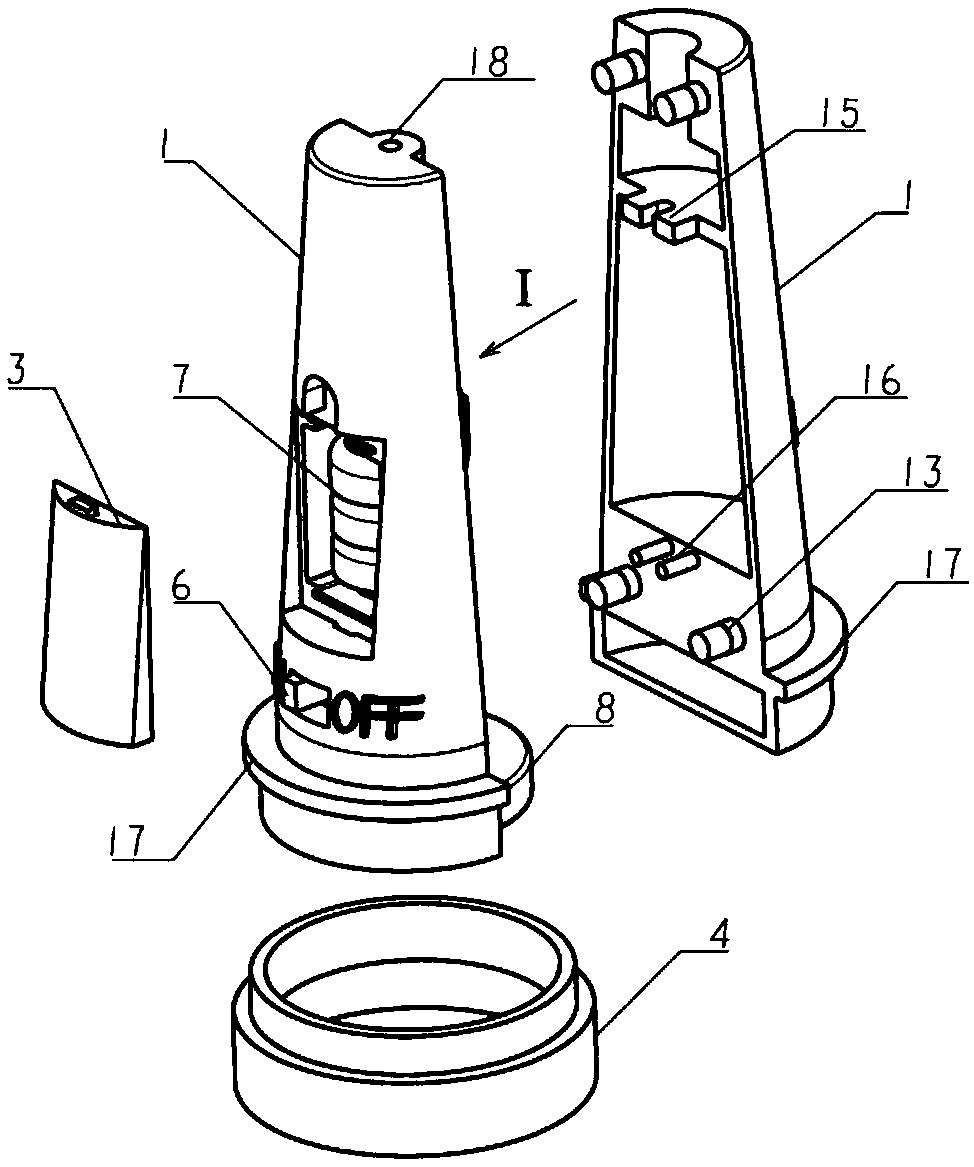

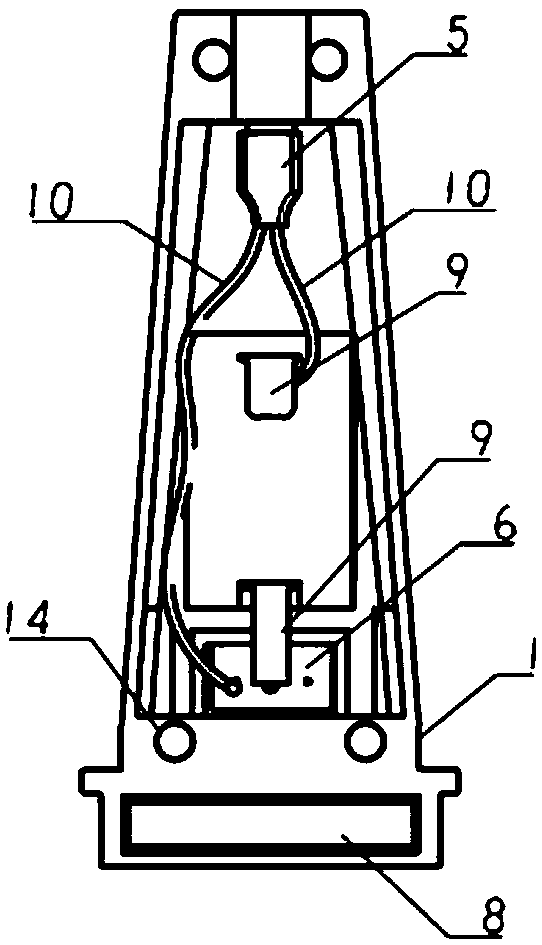

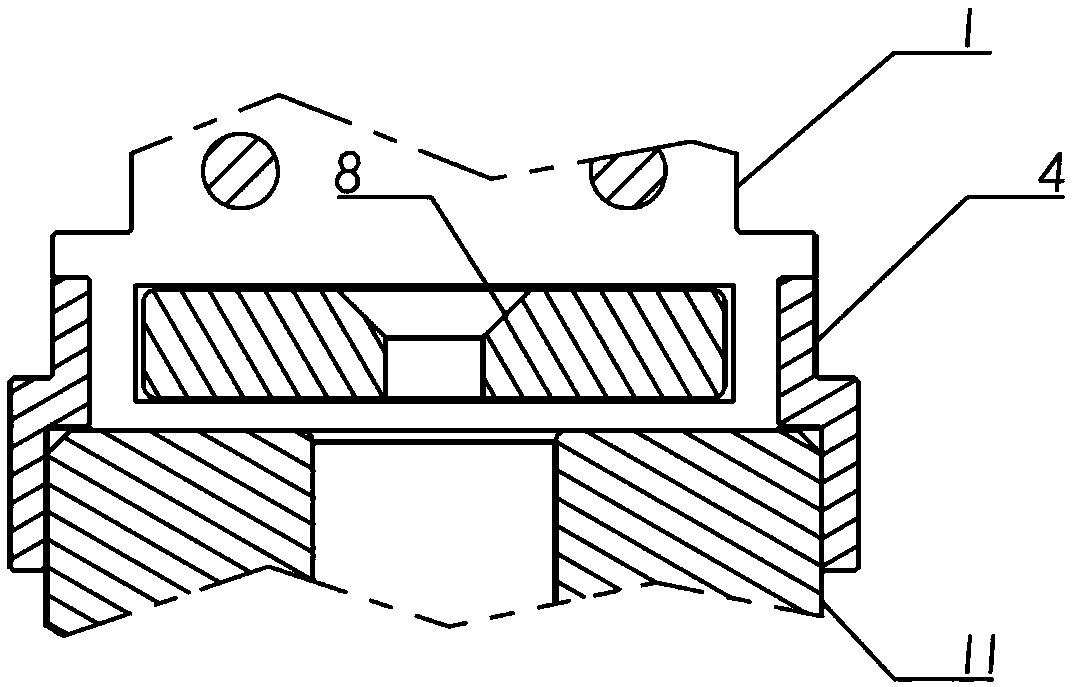

[0015] Depend on figure 1 As shown in -3, a laser tool setting device for CNC shot peening processing, including a housing 1, a semiconductor laser module 5, a battery 7, a magnet 8, and a limit sleeve 4, is characterized in that the housing is composed of left and right The half shell and the battery cover are combined, the top of the shell is provided with a laser outlet 18, the magnet 8 is installed at the bottom of the shell, the semiconductor laser module 5 and the battery 7 are installed inside the shell 1; the semiconductor laser module is composed of The semiconductor laser diode and the constant current drive circuit board are connected in series, and the laser is controlled and emitted by the switch, and the laser passes through the laser exit 18 to form a spot-like spot; the limit sleeve 4 is installed between the nozzle 11 and the shell 1 of the numerical control shot peening device, The limit sleeve 4 is a nested ring structure, the inner diameter of the upper ring i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap