Finished aluminum foil plate shape offline dynamic detecting automatic control system and use method thereof

An automatic control system and dynamic detection technology, applied in the direction of length measuring devices, metal rolling, manufacturing tools, etc., can solve problems such as low efficiency, cumbersome operations, and subjective judgment standards, and achieve the effect of improving the automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] The present invention will be further described below in conjunction with the drawings and embodiments.

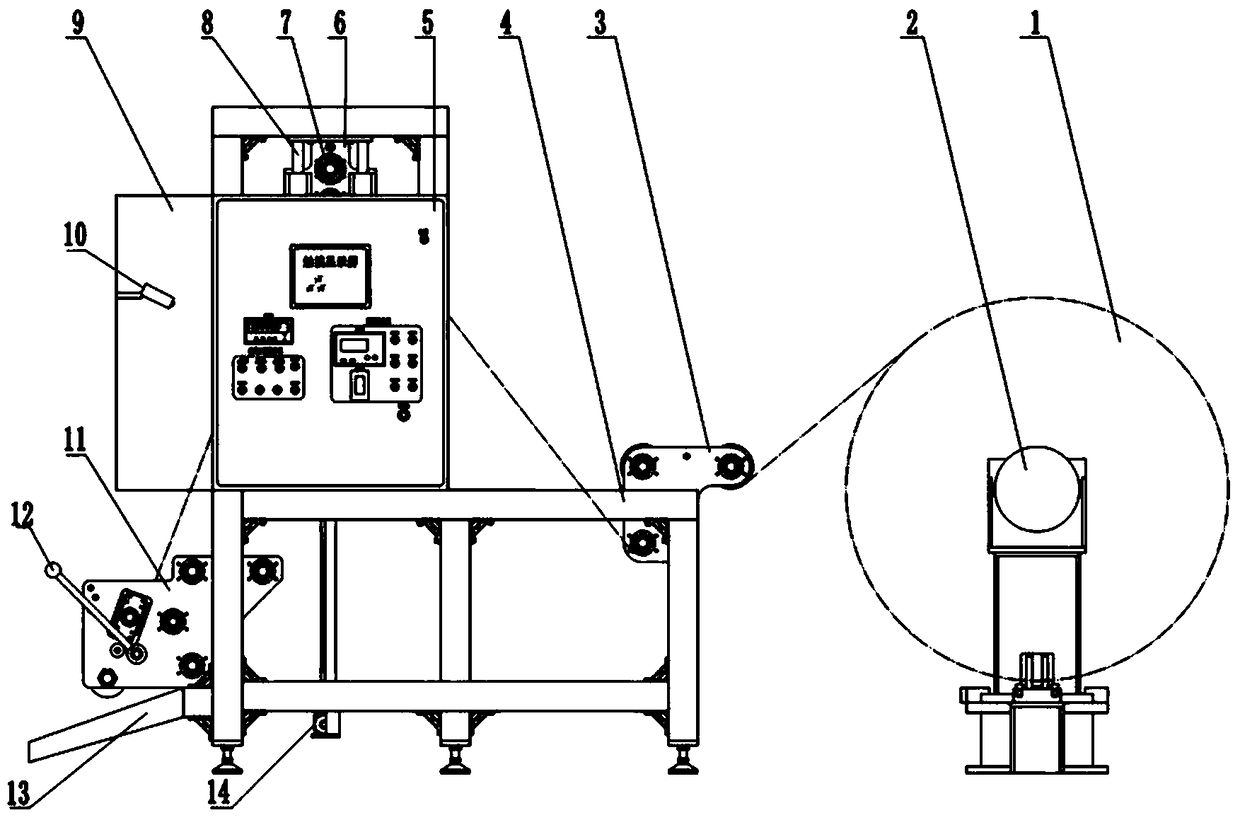

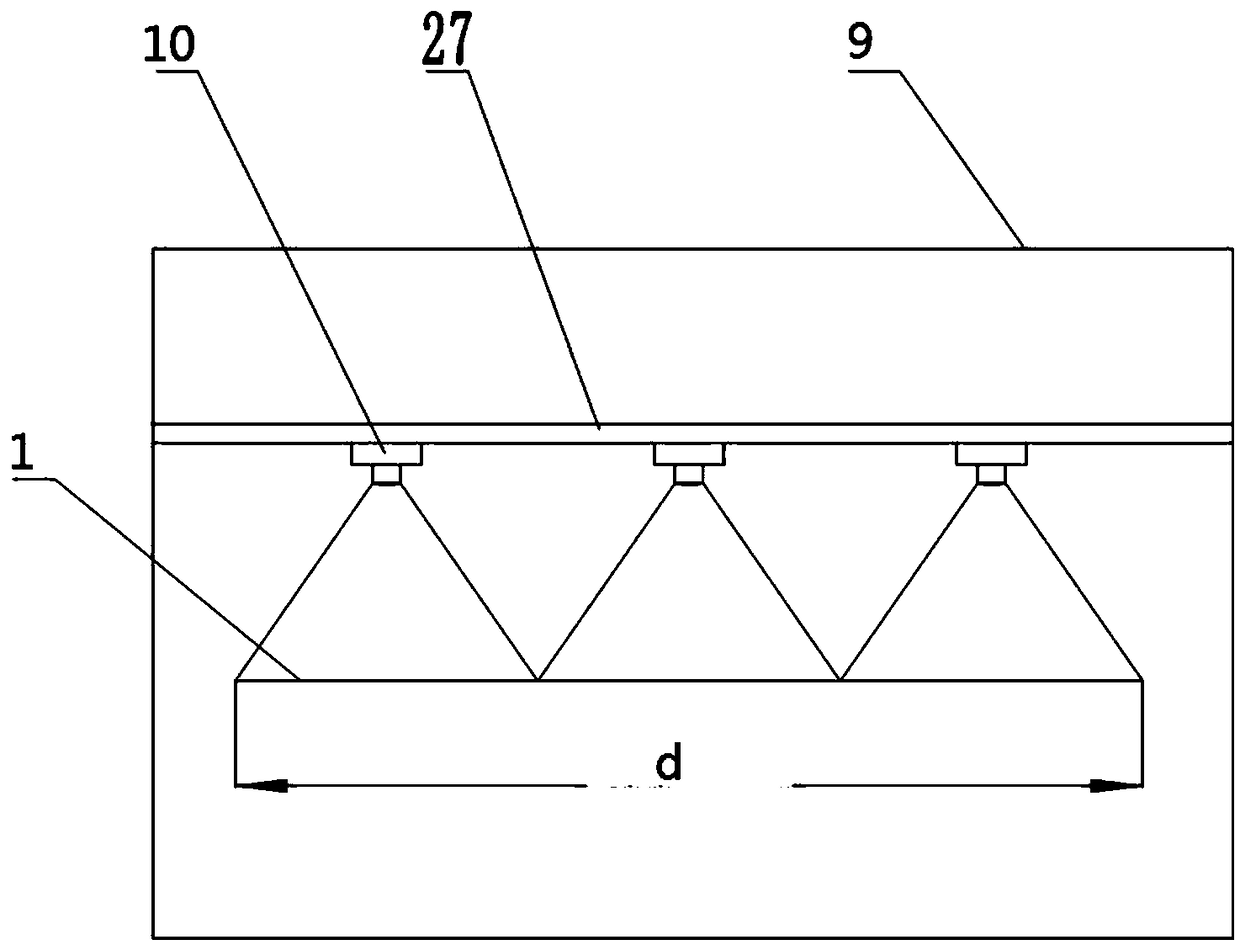

[0036] Such as Figure 1 to Figure 4 As shown, the automatic control system for offline dynamic detection of the shape of the finished aluminum foil according to the present invention includes a mechanical foil feeding system, an NX controller and a human-computer interaction interface;

[0037] The mechanical foil feeding system includes an aluminum coil installation auxiliary machine 2 and a frame 4; the aluminum coil installation auxiliary machine 2 is arranged on one side of the frame 4;

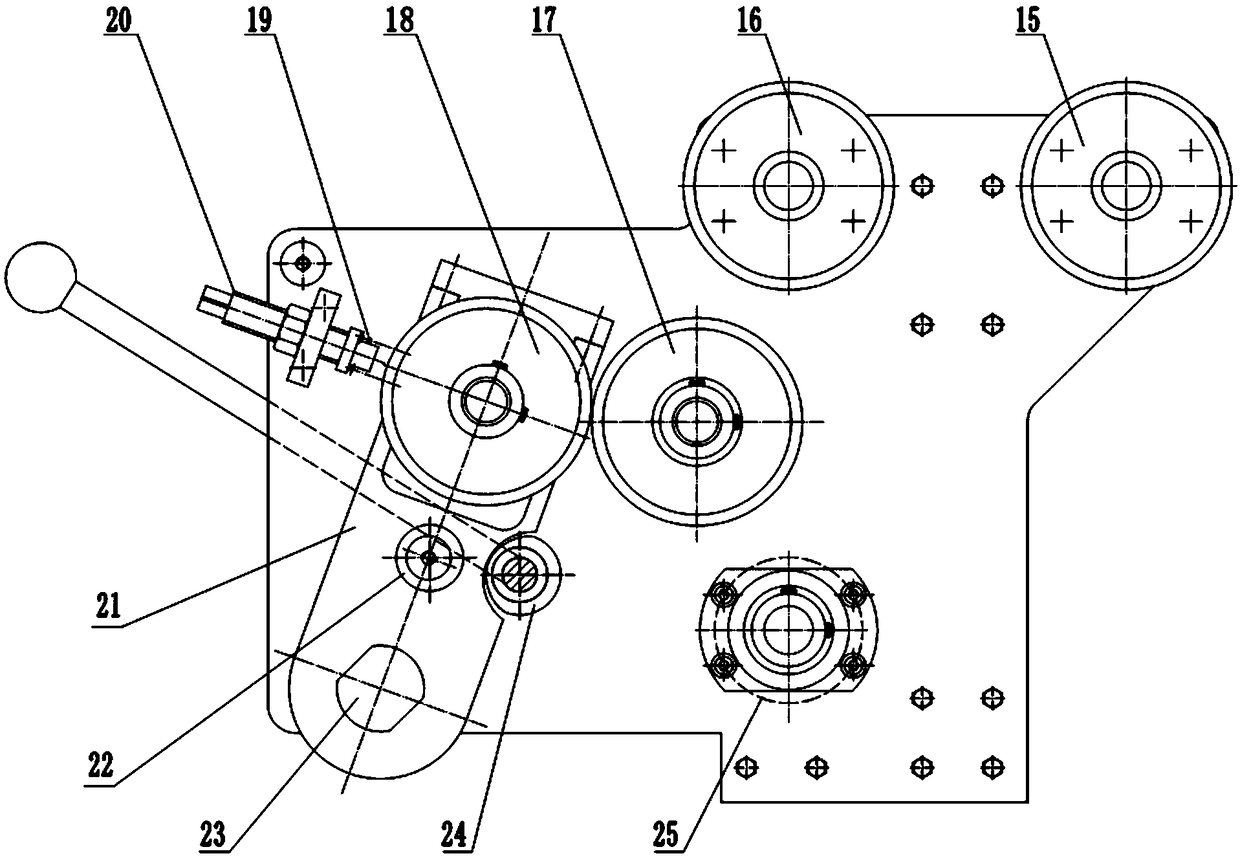

[0038] The frame 4 is provided with a control cabinet 5; the upper part of one end of the frame 4 is provided with a front stabilizing roller group 3, and the lower part of the other end of the frame 4 is provided with an automatic pretensioning device 11; A vertical cylindrical linear guide 8 is provided above 4, a transition roller set 6 is slidingly mounted on the cylindrical linear

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap