Two-dimensional transmission-type chip burning equipment

A burning equipment and conveying technology, which is applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problem of complex layout setting of processing modules and handling mechanism, reduction of chip handling efficiency and processing efficiency, and influence on chip position accuracy, etc. problem, to achieve the effect of simple and effective moving path, improving processing efficiency and handling efficiency, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

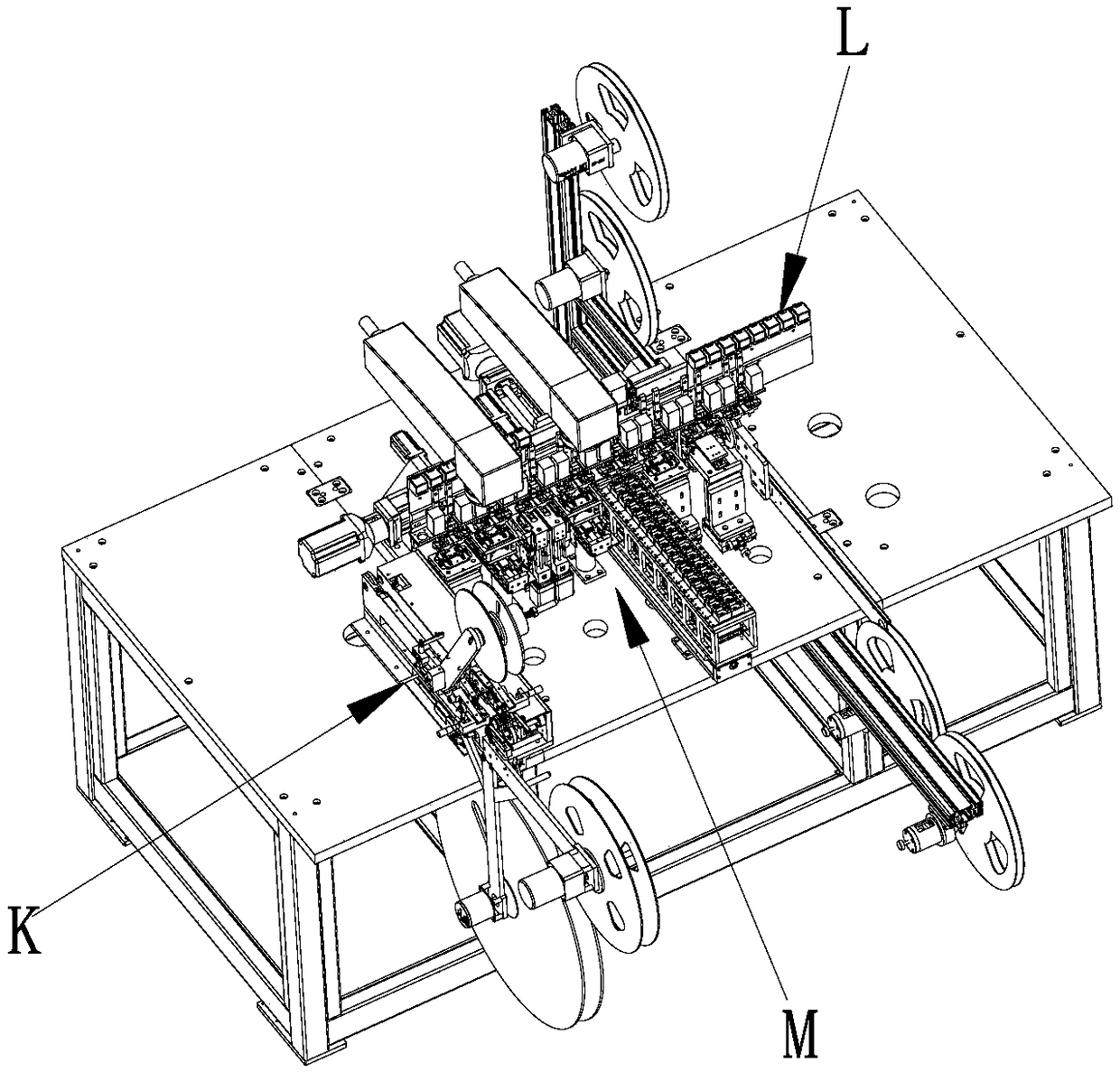

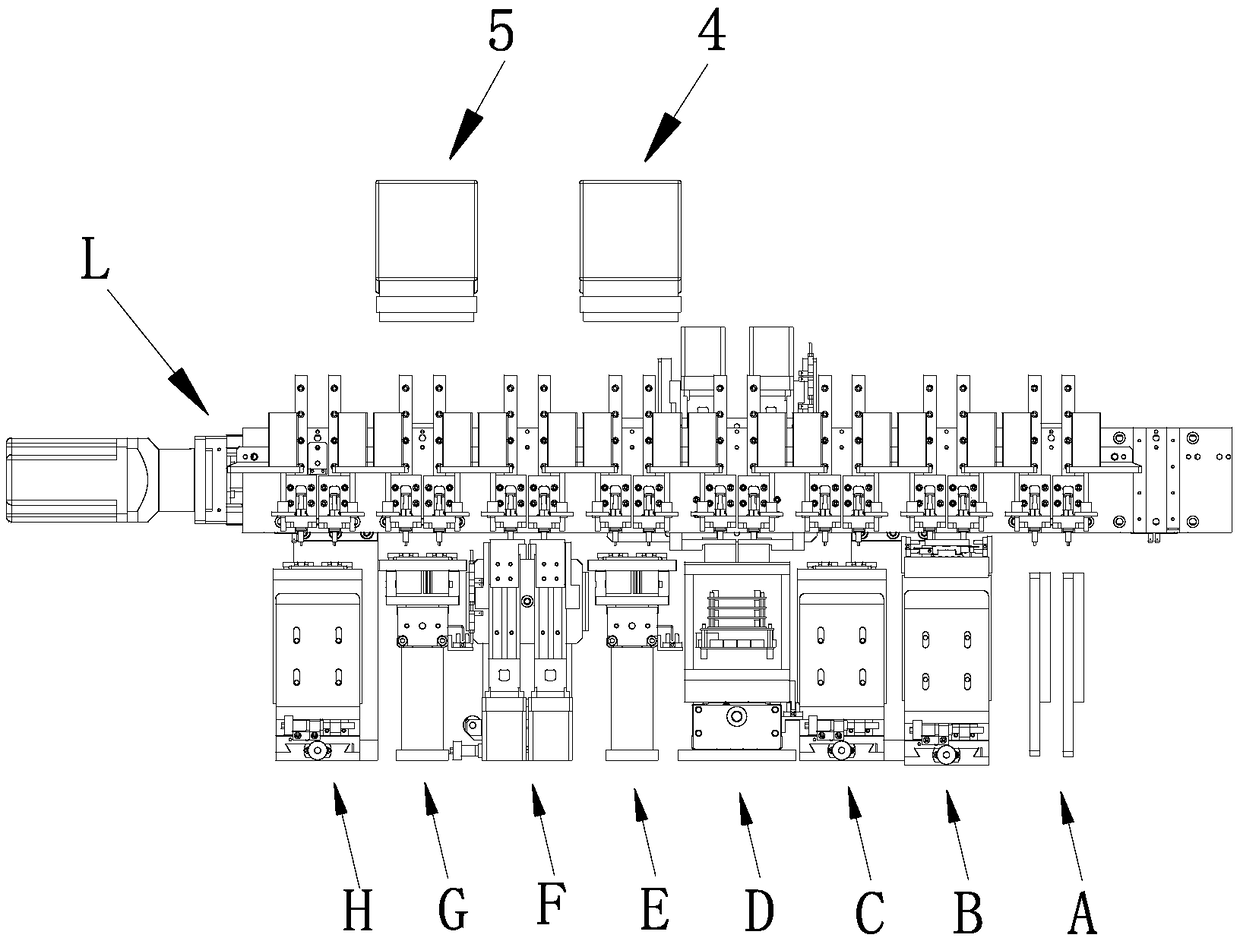

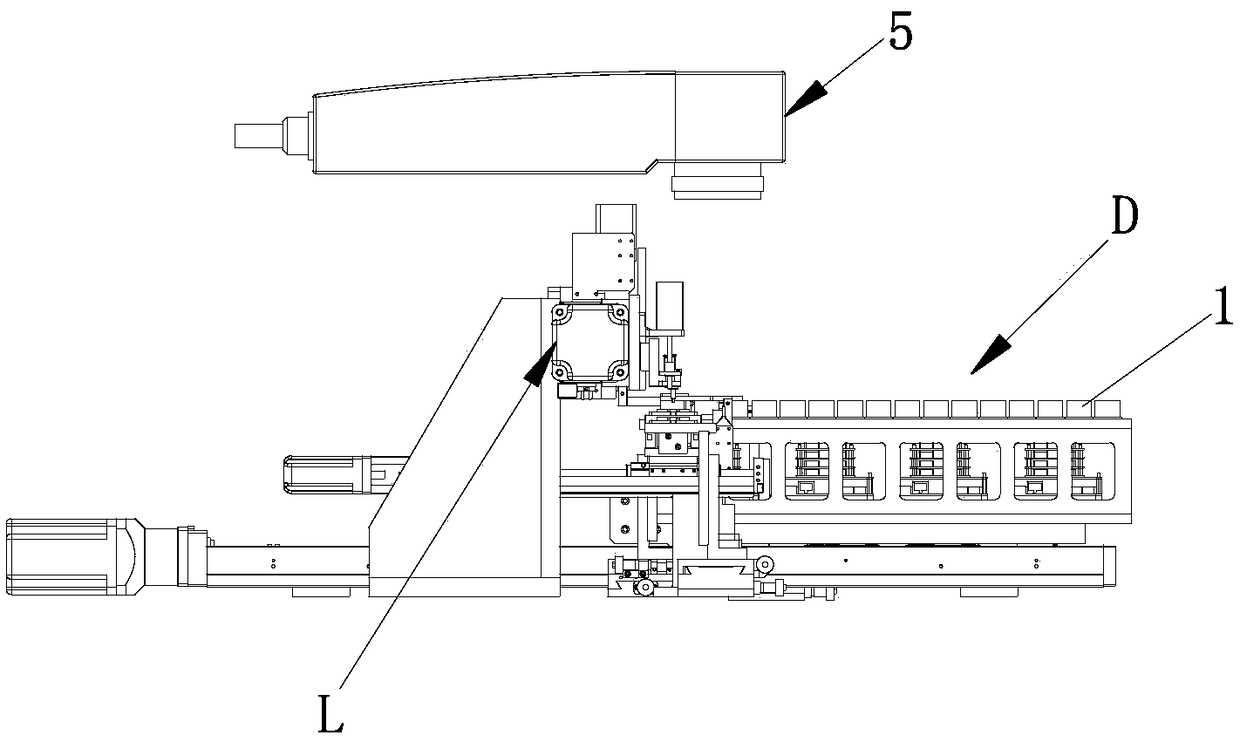

[0050] see Figure 1-Figure 6 , the chip programming device during two-dimensional transportation in this embodiment includes a chip supply module A, a processing module M, a handling module L, and a receiving and packaging module K; wherein, the processing module M includes horizontally arranged and equidistantly arranged Chip rotation positioning unit B, supplementary positioning unit C, burning unit D, laser marking unit E, burning information detection unit F, OCR detection unit G and handling temporary storage unit H on the frame; the handling module L It includes a moving plate 10 arranged above the processing unit, a horizontal driving mechanism that drives the moving plate 10 to move in the horizontal direction, and eight sets of vertical transport mechanisms P, and the eight sets of vertical tr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap