Efficient full-automatic veneering hot press production line

A fully automatic, production line technology, applied in veneer presses, plywood presses, wooden veneer joints, etc., can solve problems such as poor continuity, practicability needs to be improved, and efficient veneering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

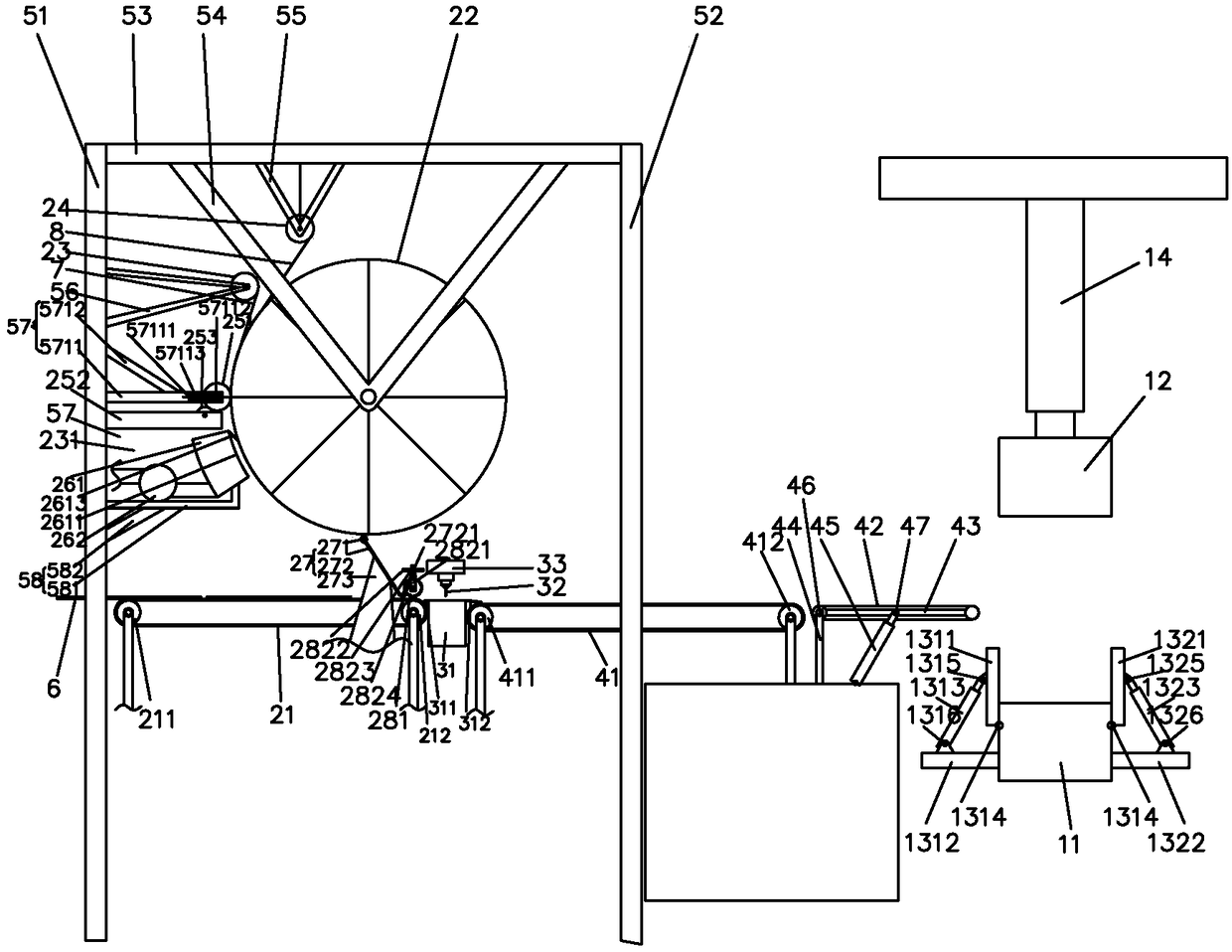

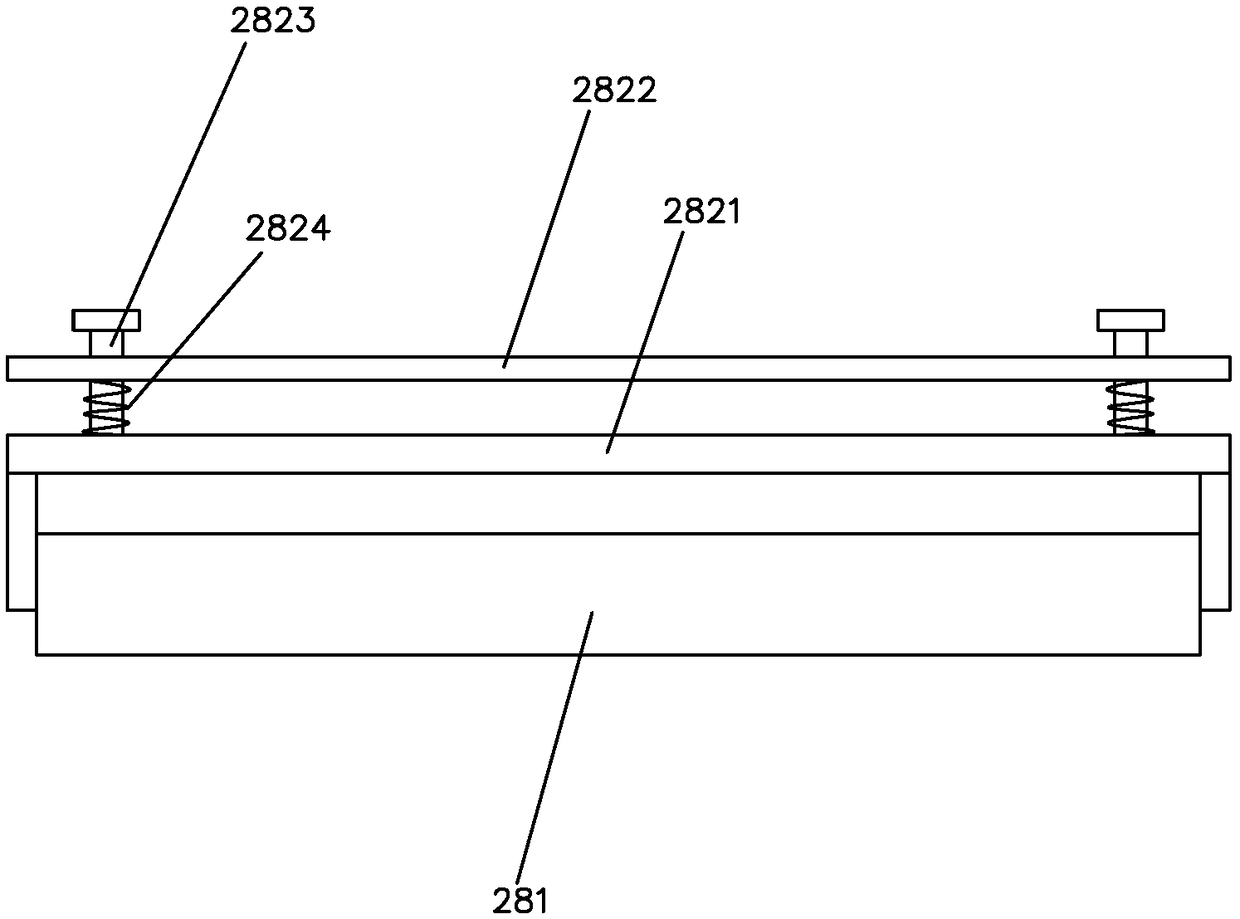

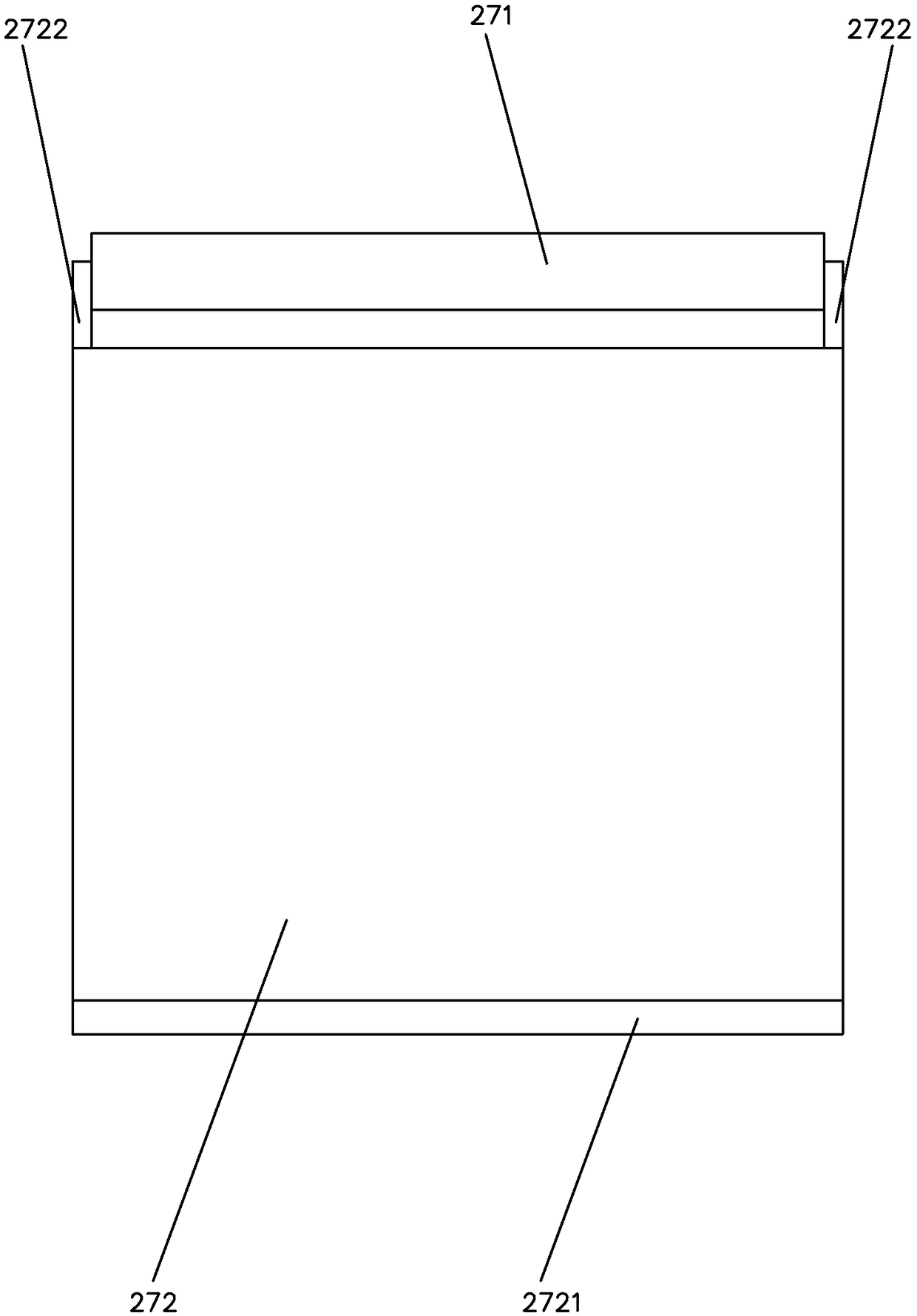

[0037] A kind of high-efficiency full-automatic veneer hot press production line of the present invention, as Figure 1-4 As shown, it includes a hot pressing device, a veneer device for forming a continuous veneer template by bonding the veneer surface layer 8 on the template blank 6, a cutting device for cutting the continuous veneer template to form a veneer template block, and veneering The template blocks are delivered to the conveying device of the hot pressing device one by one; preferably, the present invention also includes a frame that supports the veneering device and the cutting device; and the master controller for controlling the conveying device;

[0038] Preferably, the heat-pressing device comprises a heat-pressing base 11 below, a movable heat-pressing plate 12 directly above the heat-pressing base 11, an alignment de

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap