Method for preparing and detecting plane strain sample of hard alpha inclusion material in titanium alloy

A technology of plane strain and detection method, which is applied in the preparation of test samples, analysis of materials, and the use of stable tension/pressure to test the strength of materials, etc., to achieve the effect of simple operation, wide range of use, and filling data gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

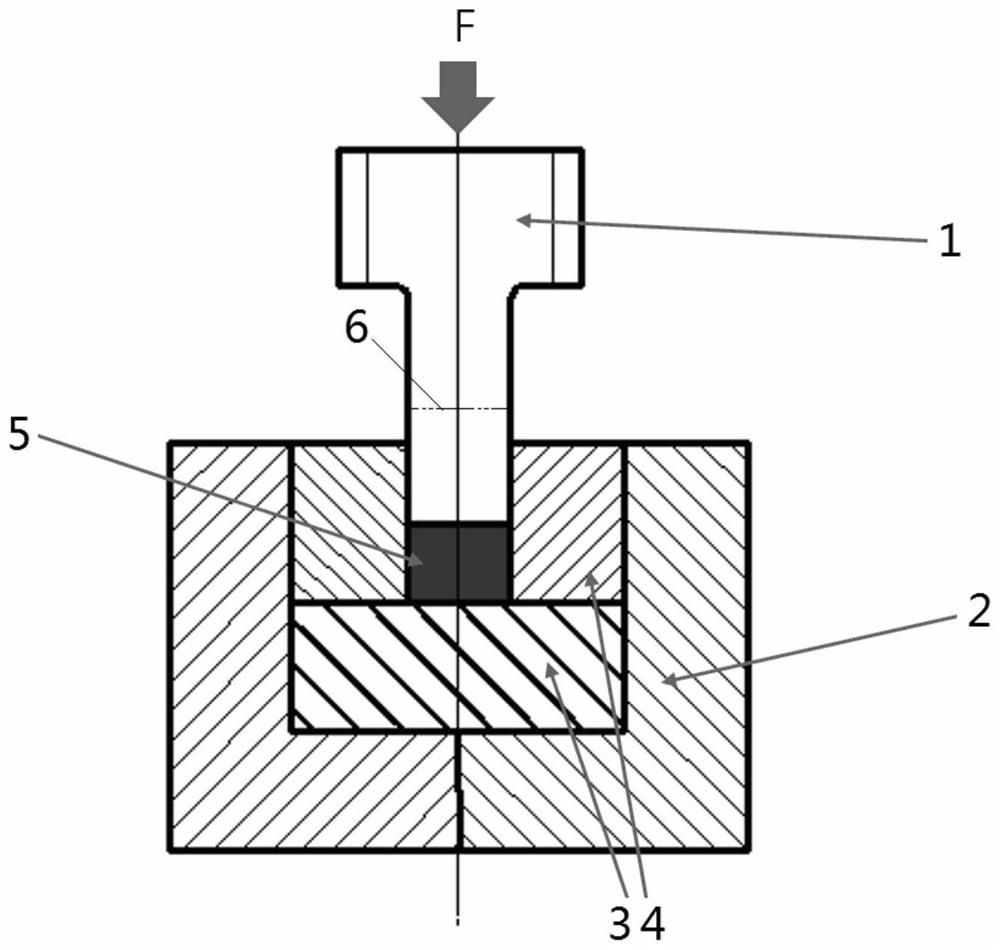

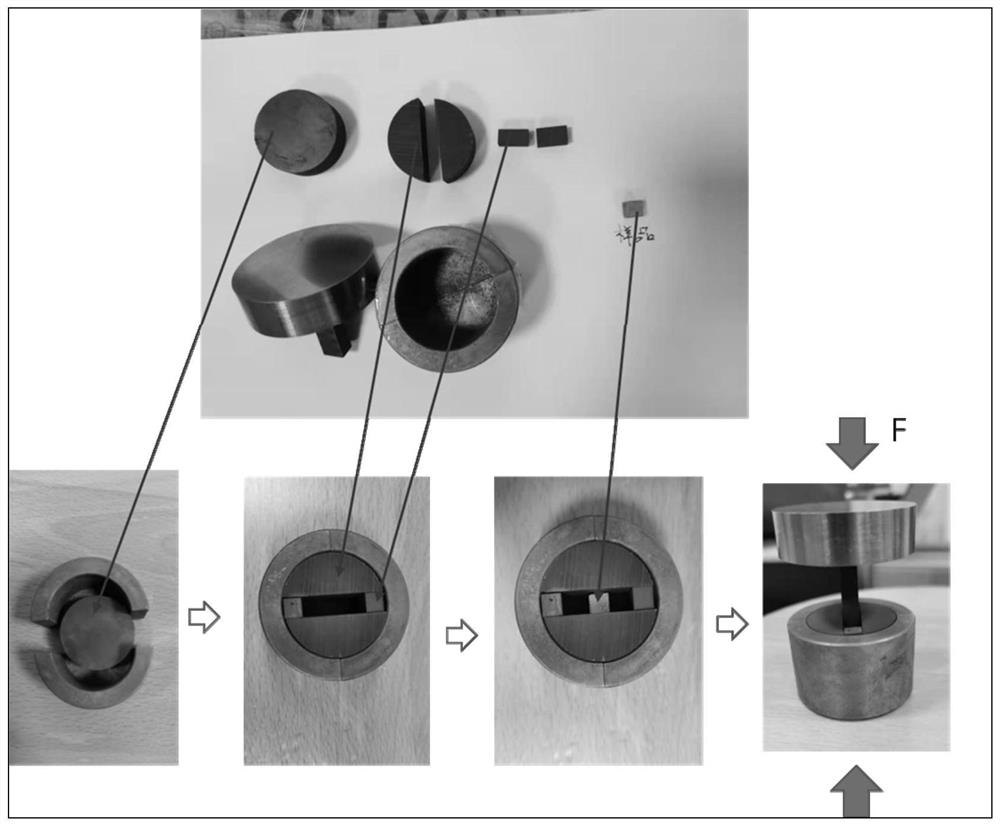

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the preparation and detection method of a TiN material plane strain sample with a nitrogen content of 2wt% includes the following steps:

[0027] (1) TiN inclusion bulk materials with different nitrogen contents were prepared by hot isostatic pressing technology, and the nitrogen content was 2wt%;

[0028] (2) The plane strain sample is processed by wire cutting, the sample is a cube with a side length of 6.35mm, and the machining allowance is 0.5mm;

[0029] (3) Use an automatic grinding and polishing machine to grind the surface of the plane strain sample to remove the oxide layer;

[0030] (4) A solution with a volume ratio of hydrofluoric acid, nitric acid and water of 1:4:10 was used for etching treatment, and the concentrations of hydrofluoric acid and nitric acid were 36wt% and 67wt%, respectively, so as to prepare a plane strain with a nitrogen content of 2wt% sample;

[0031] (5) Use a high temperature thermal compression testing machine to t

Embodiment 2

[0034] In this embodiment, the preparation and detection method of a TiN material plane strain sample with a nitrogen content of 6wt% includes the following steps:

[0035] (1) TiN inclusion bulk materials with different nitrogen contents were prepared by hot isostatic pressing technology, and the nitrogen content was 6wt%;

[0036] (2) The plane strain sample is processed by wire cutting, the sample is a cube with a side length of 6.35mm, and the machining allowance is 0.3mm;

[0037] (3) Use an automatic grinding and polishing machine to grind the surface of the plane strain sample to remove the oxide layer;

[0038] (4) Then, a solution with a volume ratio of hydrofluoric acid, nitric acid and water of 2:8:10 was used for etching treatment, and the concentrations of hydrofluoric acid and nitric acid were 38wt% and 66wt%, respectively, so as to prepare a plane with a nitrogen content of 6wt% strain specimen;

[0039] (5) Use a high temperature thermal compression testing mach

Embodiment 3

[0042] In this embodiment, the preparation and detection method of a TiN material plane strain sample with a nitrogen content of 12wt% includes the following steps:

[0043] (1) TiN inclusion bulk materials with different nitrogen contents were prepared by hot isostatic pressing technology, and the nitrogen content was 12wt%;

[0044] (2) The plane strain sample is processed by wire cutting, the sample is a cube with a side length of 6.35mm, and the machining allowance is 0.4mm;

[0045] (3) Use an automatic grinding and polishing machine to grind the surface of the plane strain sample to remove the oxide layer;

[0046] (4) The plane strain samples were corroded with a solution with a volume ratio of hydrofluoric acid, nitric acid and water of 1:7:10. The concentrations of hydrofluoric acid and nitric acid were 37wt% and 65wt%, respectively, so that the nitrogen content was prepared as 12wt% plane strain specimen;

[0047] (5) Use a high temperature thermal compression testing

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap