Automatic guided vehicle

An automatic guided vehicle and vehicle body technology, applied in the direction of motor vehicles, vehicle components, non-electric variable control, etc., can solve problems such as poor steering, and achieve the effect of flexible steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings.

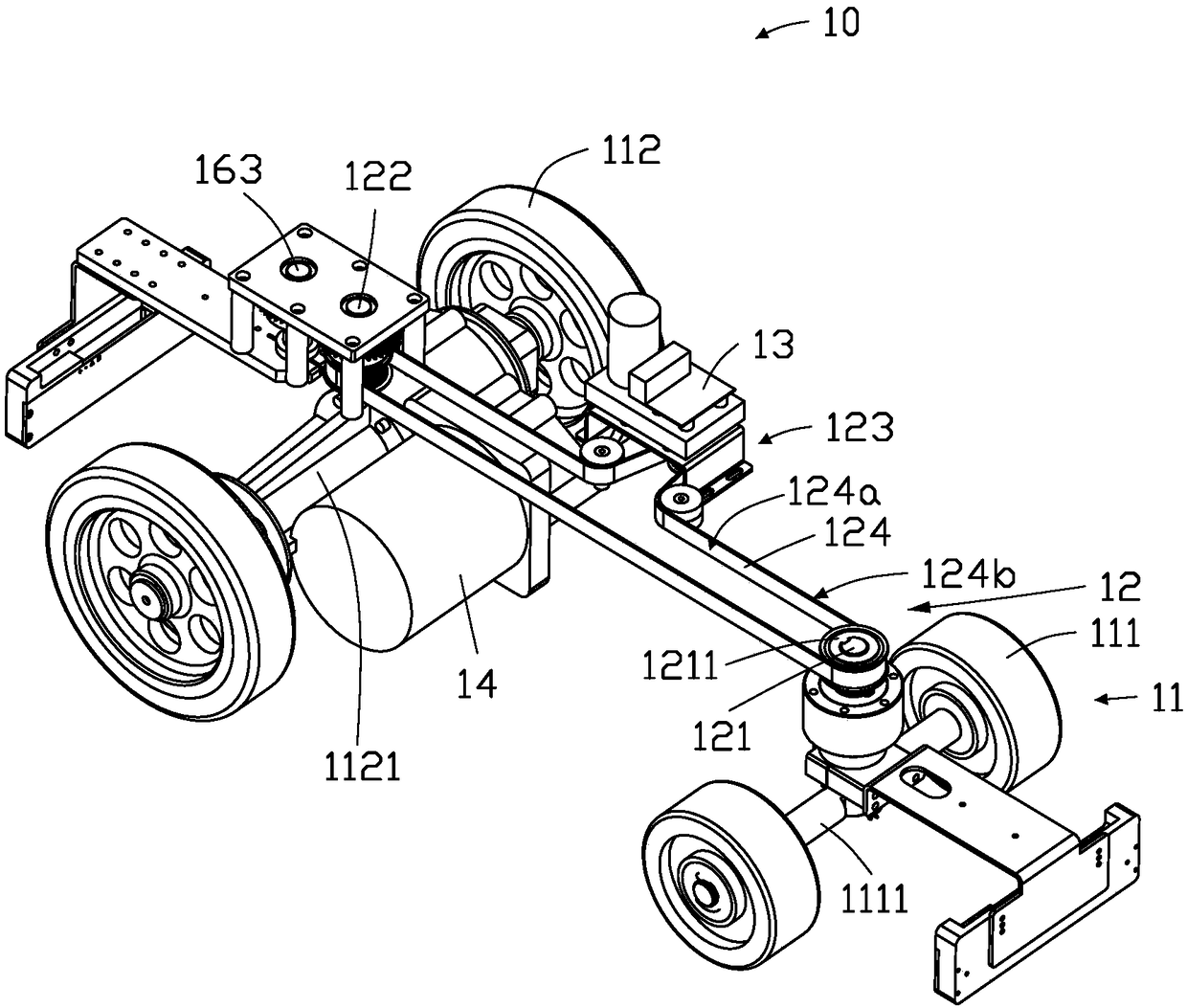

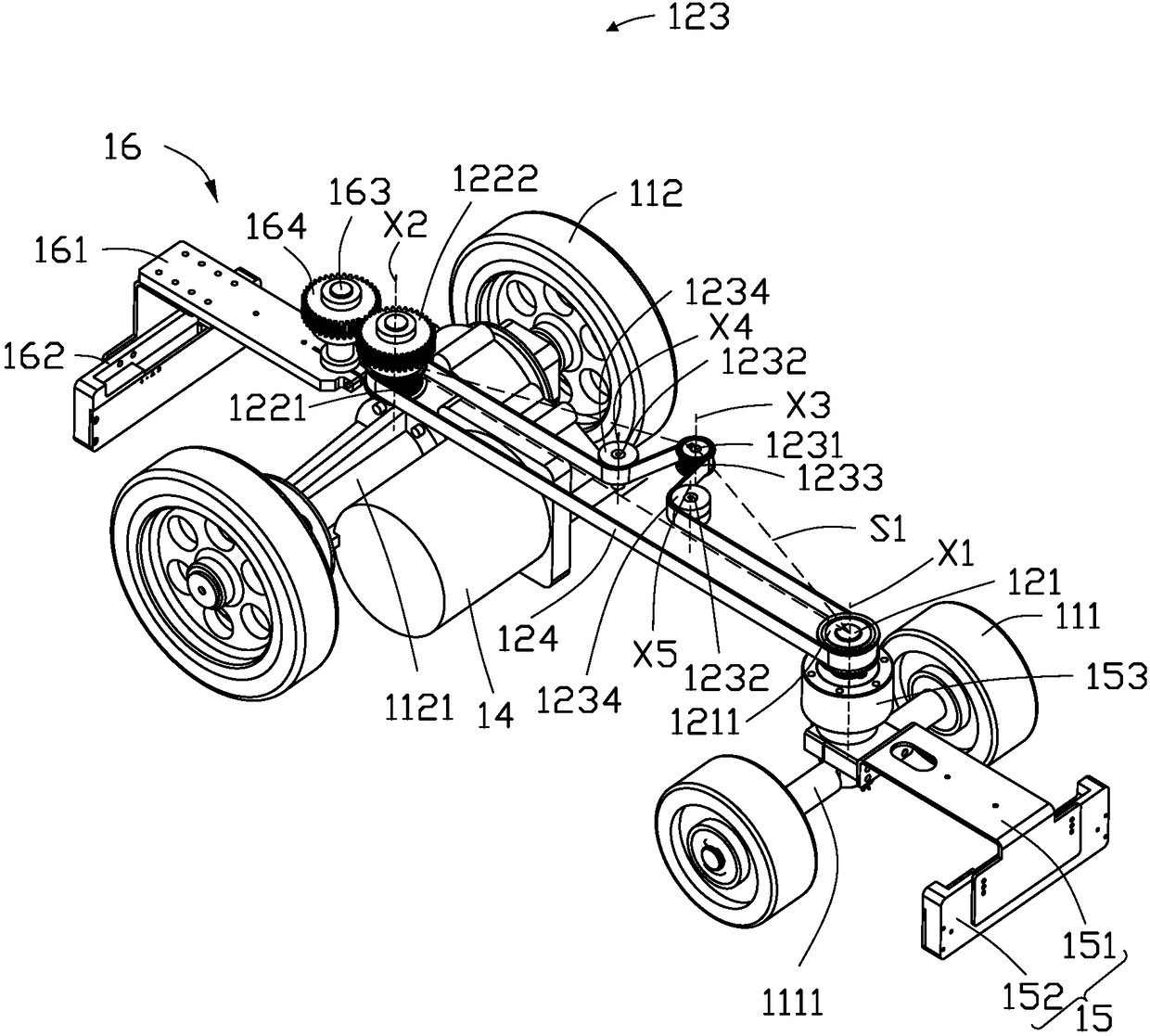

[0044] see Figure 1-2 , the present invention provides an automatic guided vehicle 10 . The automatic guided vehicle 10 includes a body part 11 , a steering part 12 , a control part 13 and a driving part 14 .

[0045] The vehicle body 11 includes two front wheels 111 and two rear wheels 112 . The vehicle body part 11 also includes supporting structures such as a chassis (not shown in the figure) and a compartment (not shown in the figure). A front wheel shaft 1111 is connected between the two front wheels 111 , and a rear wheel shaft 1121 is connected between the two rear wheels 112 . In this embodiment, the outer peripheries of the two front wheels 111 and the two rear wheels 112 are made of rubber.

[0046] The driving part 14 is disposed on the rear wheel shaft 1121 , and the driving part 14 drives the rear wheel shaft 1121 to rotate, thereby driving the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap