Electrically-controlled multi-station multi-type injection valve performance detection device and detection method

A detection device and injection valve technology, applied in fuel injection devices, measuring devices, charging systems, etc., can solve problems such as inaccurate injection timing and injection volume, low combustion efficiency, and reduced service life, so as to achieve fuel saving and The effect of labor cost, reduction of failure probability, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The present invention will be further explained below in conjunction with the drawings, but the protection scope of the present invention should not be limited by this.

[0025] The invention detects the performance of the drive valve by simulating the way the diesel engine drives the injection valve, provides an effective detection method for the injection valve, and reduces the probability of diesel engine failure due to unqualified injection valve performance.

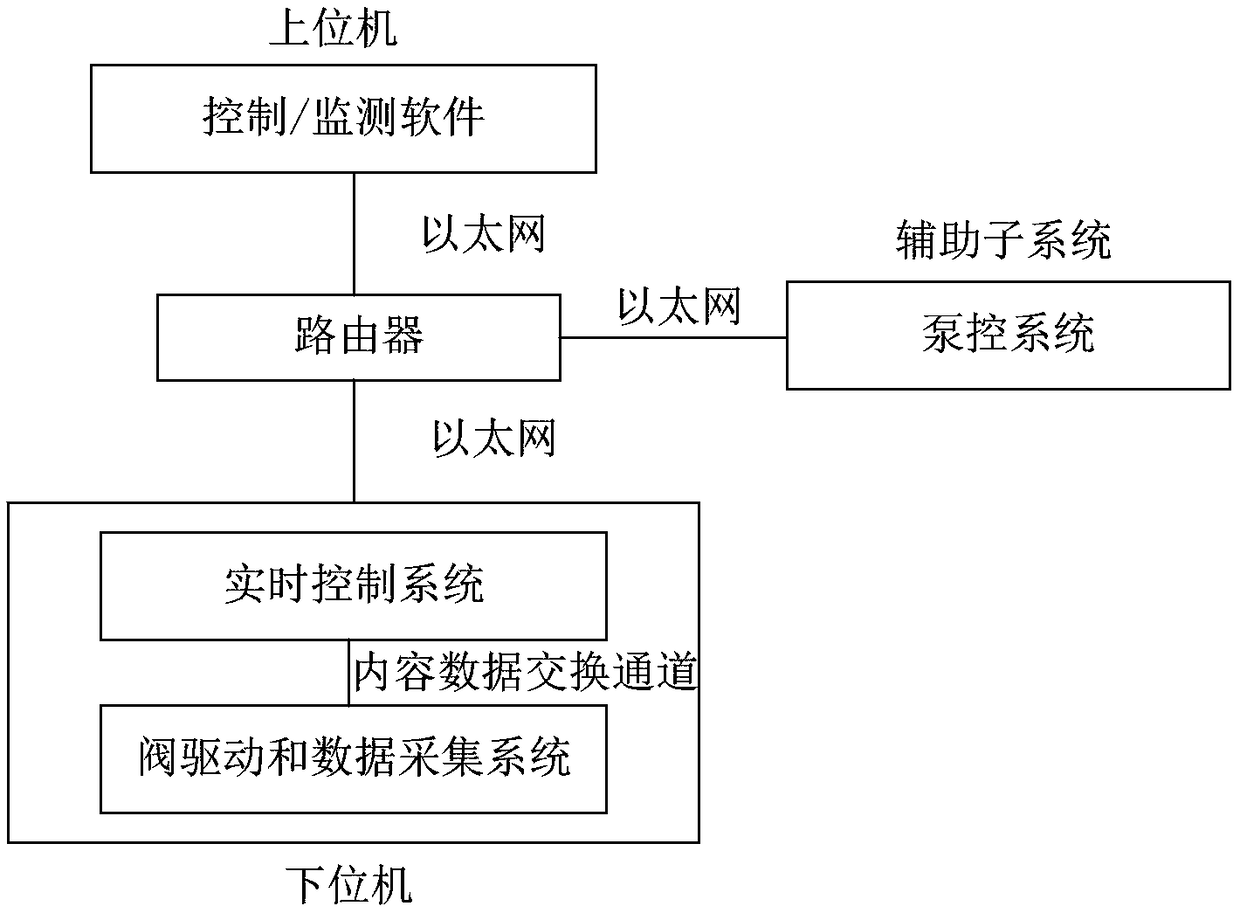

[0026] See figure 1 , figure 1 It is a schematic diagram of the structure of the detection device, including the upper computer, the lower computer, the router and the auxiliary subsystem, among which:

[0027] The host computer is composed of a high-performance computer with a set of control and monitoring software inside; it is used to control, monitor and manage the entire valve performance testing device, store test data, and calculate test results;

[0028] The auxiliary subsystem is a pump control system, which i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap