Primary filtering device for treating volatile organic compounds and operation method

A volatile organic compound and primary-effect filtration technology, which is applied in the field of purification systems, can solve problems such as high cost of filtration devices, blockage of internal fiber fabric layers, shutdowns, etc., and achieve significant application value and improve use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the drawings and embodiments.

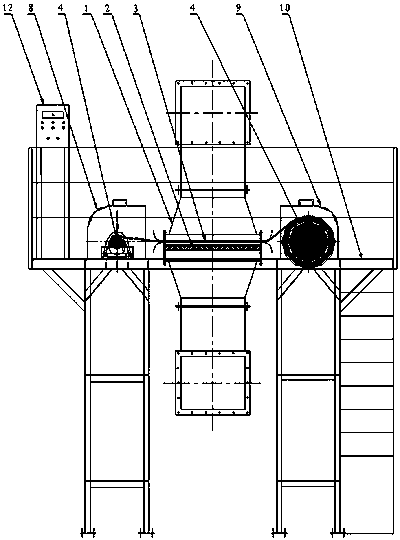

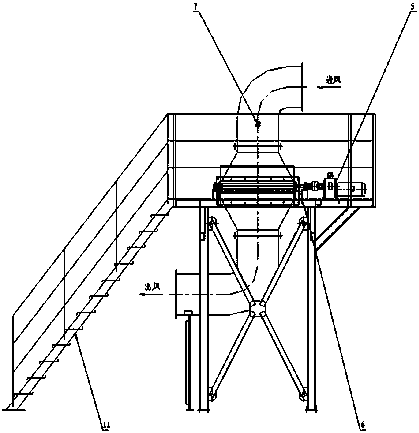

[0030] See figure 1 with figure 2 , The present invention provides an initial filtering device for treating volatile organic compounds, which is mainly composed of a frame, a working platform 10 installed on the frame, a preliminary filter chamber 1, a reducer 5, a driving shaft and a driven shaft 4, and an outer casing , Polymer adsorption board 2, polymer filter felt 3, photoelectric sensor switch 6, differential pressure transmitter 7 and PLC control system 12.

[0031] The primary filter chamber 1 is arranged in the middle of the working platform 10, the top of the primary filter chamber 1 is equipped with an air inlet pipe, and the bottom of the primary filter chamber 1 is equipped with an air outlet pipe. The primary filter chamber 1 is connected to the reducer 5 and the winding device, and the driving shaft and the driven shaft 4 are respectively arranged on both

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap