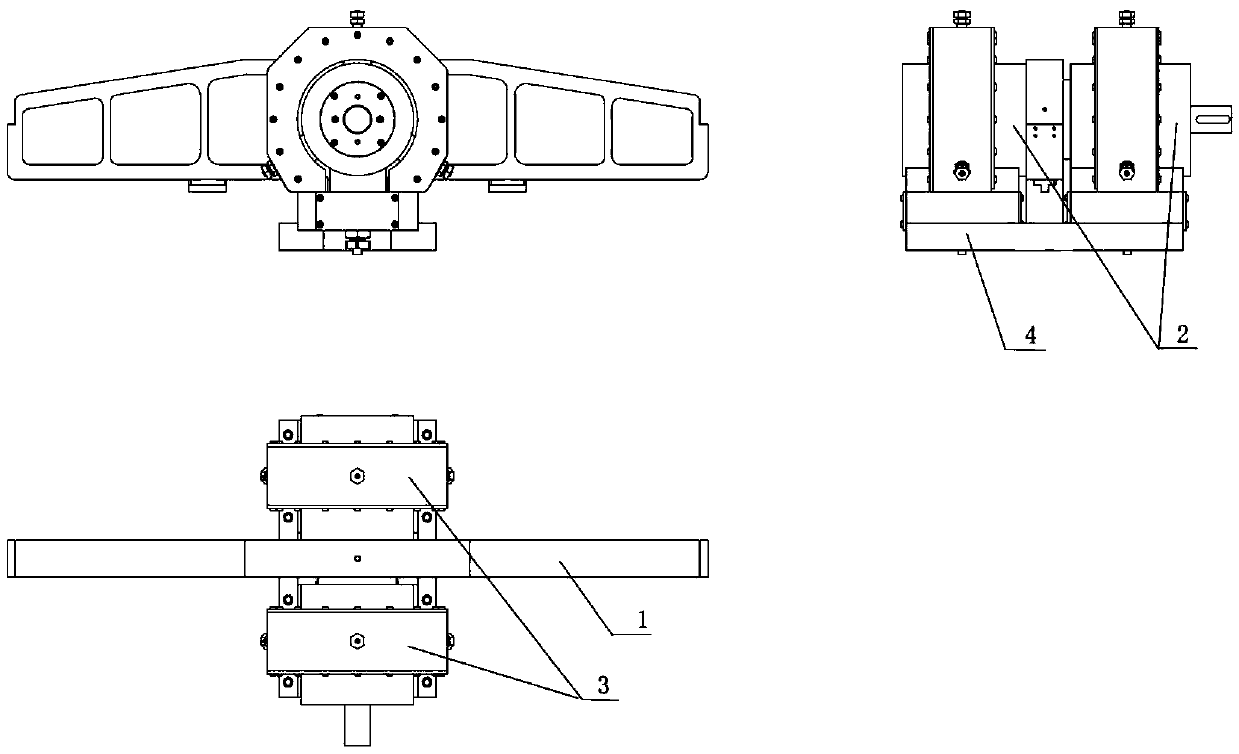

Combined type aerostatic bearing support mechanism

A technology of air bearings and floating bearings, which is applied in the direction of measuring devices, instruments, force/torque/power measuring instruments calibration/testing, etc., and can solve the difficulty and measurement uncertainty of accurate measurement of the positional relationship of the three knives It is difficult to control at an ideal level, which affects the sensitivity and accuracy of the device, and achieves the effect of convenient and flexible structural design and capacity expansion, obvious plasticity, and loose working environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specifically, the moment arm lever is supported stably in the form of a bridge through the central circular shaft support and the two sets of combined static pressure air bearings. When working, high-pressure gas is introduced into the bearing system made of dense microporous non-metallic materials, and the gas is evenly released through the dense micropores. The high-pressure gas in the tiny gap between the bearing cavity and the central shaft makes the entire arm lever in suspension state, while being stabilized to be confined to the center of the bearing, it can also ensure that there is extremely small frictional resistance when rotating around the central axis.

[0027] The combined static pressure air bearing support mechanism is generally used in a standard torque generating device. On the one hand, it can support loads such as the lever of the moment arm and the weight for generating torque, and on the other hand, it can also ensure that the force exerted on the lev

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap