MVR evaporator of skid-mounted single-screw compressor

An evaporator and compressor technology, applied in the field of MVR evaporator, can solve the problems of increased energy consumption, equipment energy loss, complicated operation, etc., and achieve the effects of stable feeding and discharging, stable automatic control, and improving conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An MVR evaporator according to an embodiment of the present invention will be specifically described below with reference to the accompanying drawings.

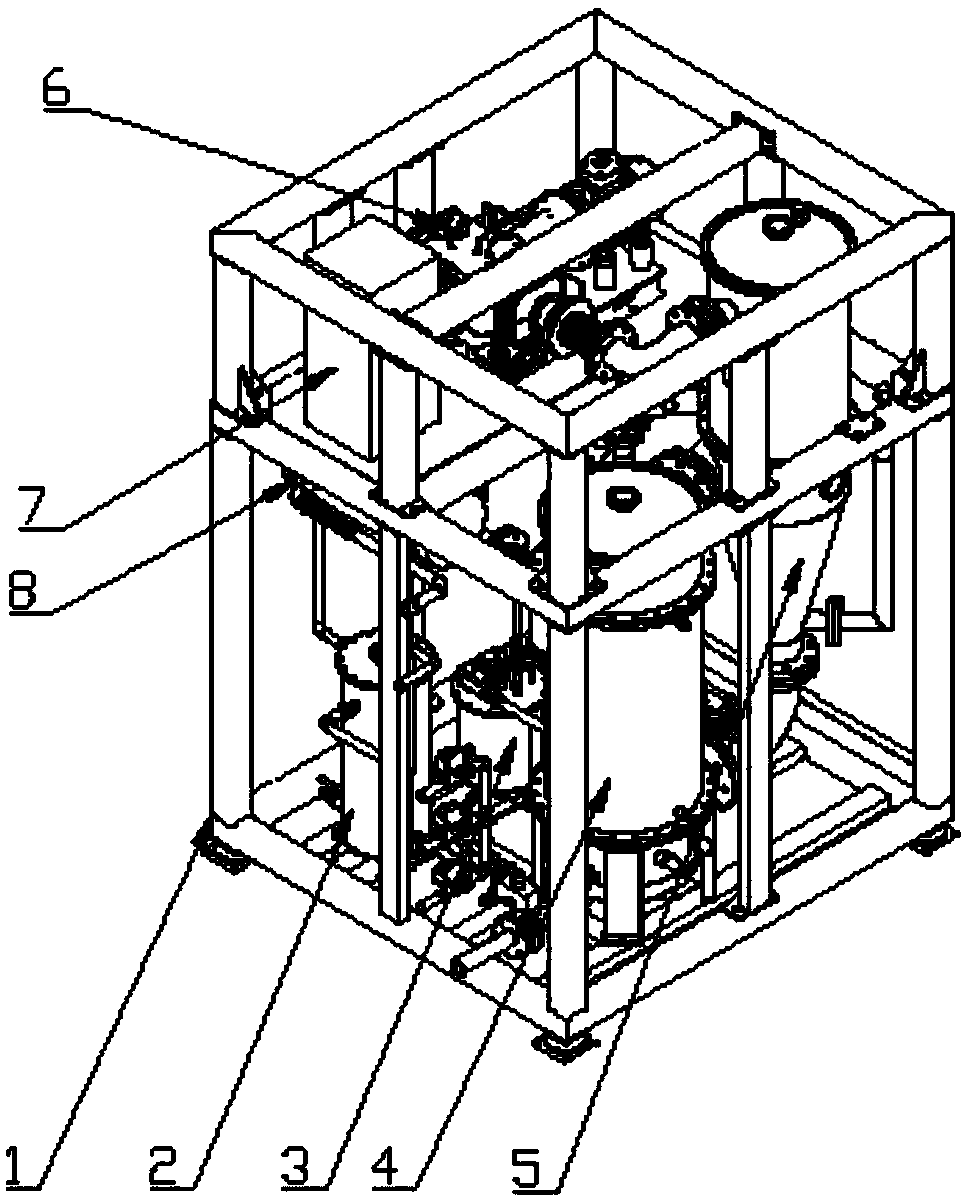

[0024] like figure 1 As shown, the MVR evaporator of an embodiment of the present invention has a frame 1, which is divided into a first layer and a second layer; it also has a preheater 2, a heat exchanger 4, a cyclone separator 5, a single screw compression Machine 6, oil pump 7, non-condensable gas heat exchanger 8, and condensed water tank 3. Wherein, the preheater 2 is horizontally installed on the bottom of the first layer of the frame 1; the heat exchanger 4 is vertically installed on the other side relative to the preheater 2 on the first layer of the frame 1; the cyclone separator 5 is connected with the heat exchange 4 adjacent, and installed in the frame 1 through the first floor and the second floor; single-screw compressor 6 installed on the second floor of the frame 1; oil pump 7 installed on the second flo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap