Ink-jet printing equipment for preparing quantum dot color filter

An inkjet printing equipment, quantum dot technology, applied in printing devices, printing, typewriters, etc., can solve the problem of more volatilization of polymerizable monomer components, and achieve the effect of reducing more volatilization and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The technical solutions in the embodiments of the present application will be described in detail below in conjunction with the implementation manners of the present application. It should be noted that the described implementations are only a part of the implementations of this application, not all of the implementations.

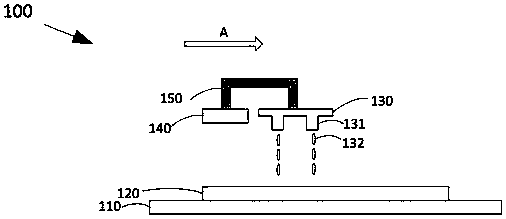

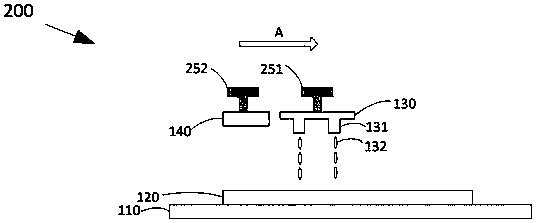

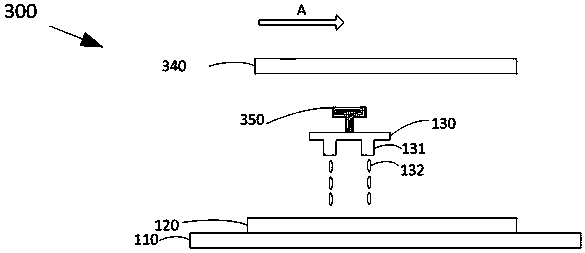

[0021] According to some exemplary embodiments of the present application, there is provided an inkjet printing apparatus for preparing a quantum dot color filter, including: a supporting member for supporting a pixel substrate; a print head for supporting a pixel supported by the supporting member The substrate ejects quantum dot glue, and the print head has a plurality of ejection outlets arranged for ejecting quantum dot glue; ultraviolet irradiating parts, which are used to irradiate ultraviolet rays to the pixel substrate to make it adhere to the pixel substrate The quantum dot glue is solidified; and the first moving part is mounted so that the prin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap