PPTA rinsing machine based on ultrasonic waves

An ultrasonic and water washing machine technology, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of reducing the ash content of PPTA resin, and achieve the effect of good effect, stable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1:

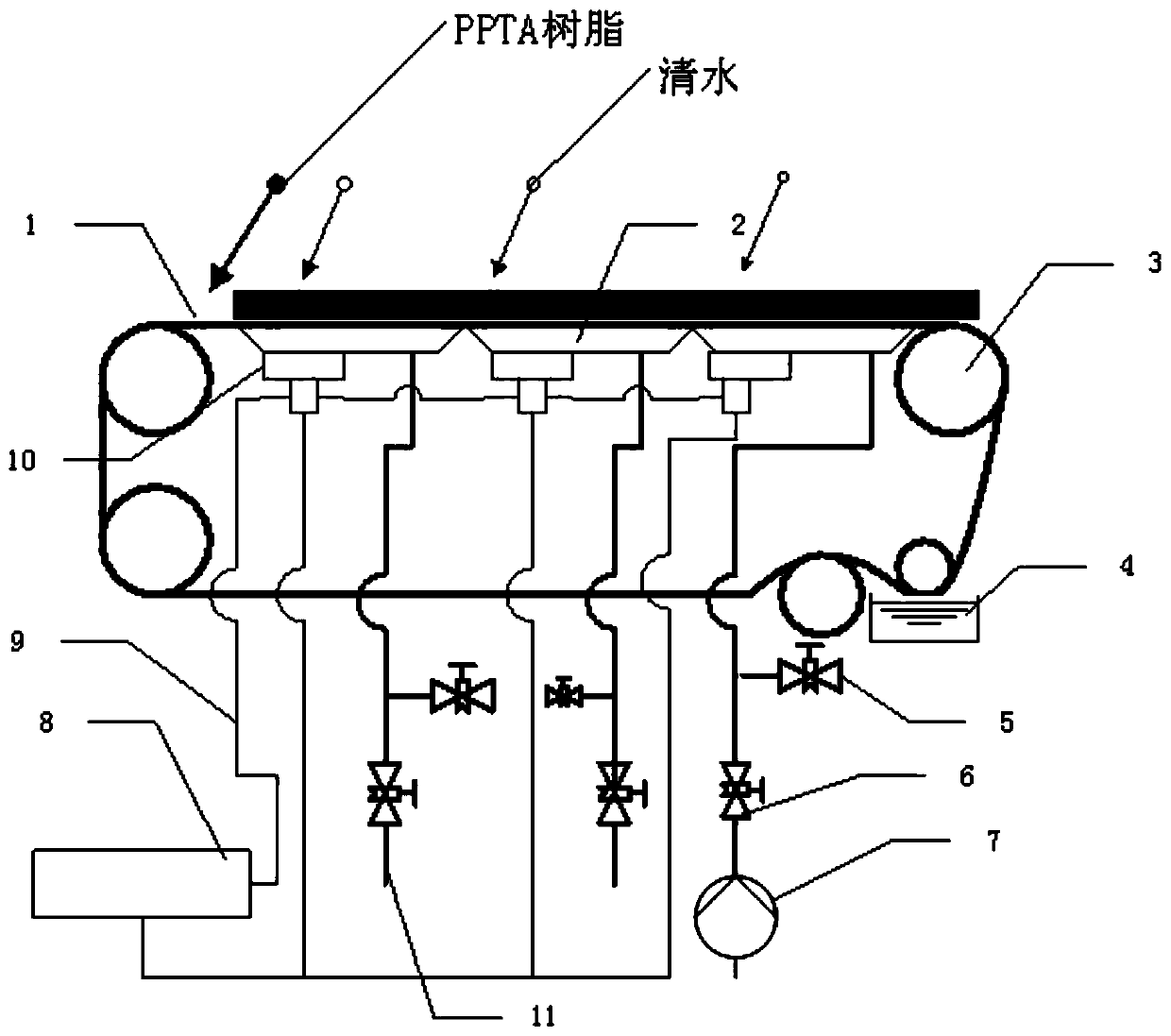

[0022] Such as figure 1 , An ultrasonic-based PPTA washing machine for washing organic solvents, co-solvents and other macromolecular impurities inside PPTA resin, including: filter cloth 1, cleaning tank 2, conveyor 3, filter cloth washing tank 4, vent valve 5. Vacuum valve 6, vacuum pump 7, ultrasonic generator 8, cable 9, ultrasonic transducer, pumping pipe 11.

[0023] The filter cloth 1 is installed on the conveyor 3, and the cleaning tank 2 is installed under the filter cloth 1, and does not move with the filter cloth 1. The ultrasonic transducer 10 is installed under the cleaning tank 2, and the ultrasonic transducer 10 passes through two cables 9 is connected to the ultrasonic generator 8; the ultrasonic generator 8 is connected to 50Hz alternating current, the suction pipe 11 is connected to the lower right of the cleaning tank 2, and the end of the suction pipe 11 is connected to the vent valve 5 and the vacuum valve 6 in turn. The vent valve 5 and the v

Example Embodiment

[0024] Example 2:

[0025] An ultrasonic-based PPTA washing machine, including: filter cloth 1, cleaning tank 2, conveyor 3, filter cloth washing tank 4, vent valve 5, vacuum valve 6, vacuum pump 7, ultrasonic generator 8, cable 9, ultrasonic changer Energy device, pumping pipe 11. The filter cloth 1 is installed as a filter medium and a transmission belt on the conveyor 3, the cleaning tank 2 is installed under the filter cloth 1, the ultrasonic transducer 10 is installed under the cleaning tank 2, the ultrasonic transducer 10 is connected by two cables 9 To the ultrasonic generator 8, the ultrasonic generator 8 is connected to a 50Hz alternating current, the suction pipe 11 is connected to the lower right of the cleaning tank 2, the end of the suction pipe 11 is connected to the vent valve 5 and the vacuum valve 6 in turn, and the vacuum pump 7 is installed at one end of the vacuum valve 6. , The filter cloth washing tank 4 is installed at the lower right of the conveyor 3. The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap