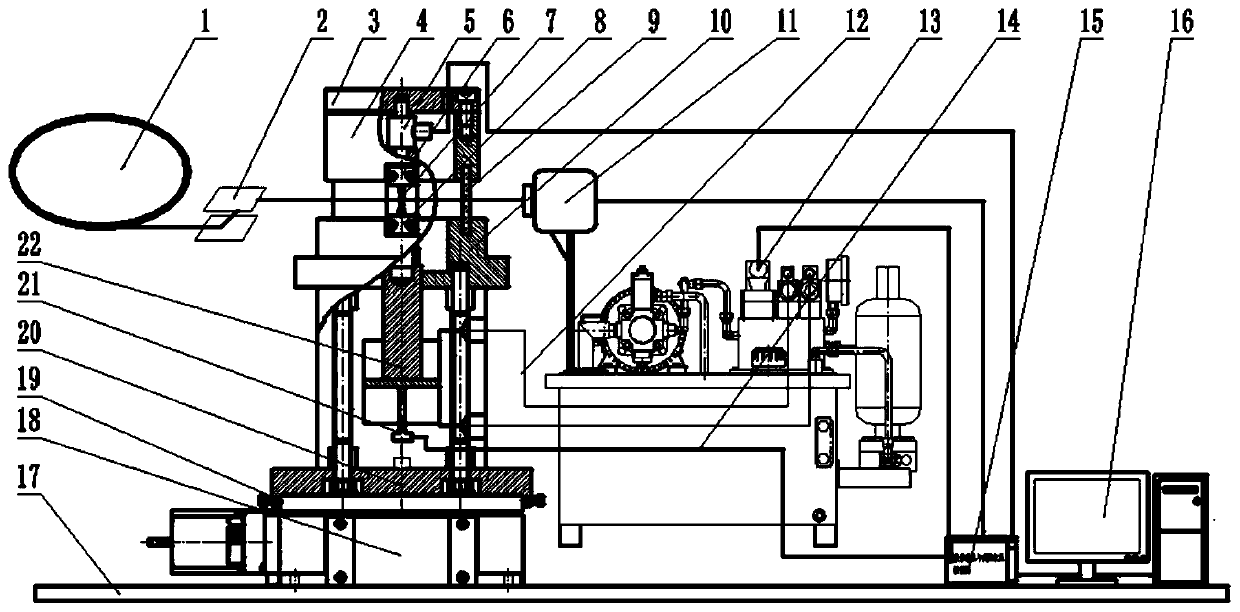

Large-load and high-frequency in-situ tension and fatigue tester based on X-ray imaging

A fatigue testing machine and in-situ stretching technology, applied in the direction of applying stable tension/compression to test the strength of materials, using radiation for material analysis, and using applied repetitive force/pulsation force to test the strength of materials, etc., can solve the problem that cannot be exerted Advanced light source detection capabilities, inability to test and characterize high-strength materials, long loading time and other issues, to achieve long life, high load, and fast frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] The present invention will be described in detail below in conjunction with the drawings.

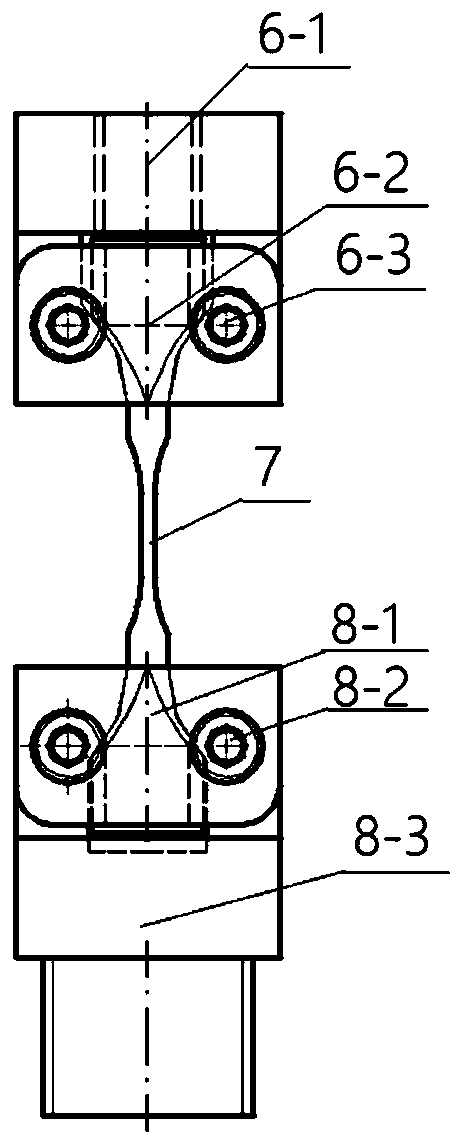

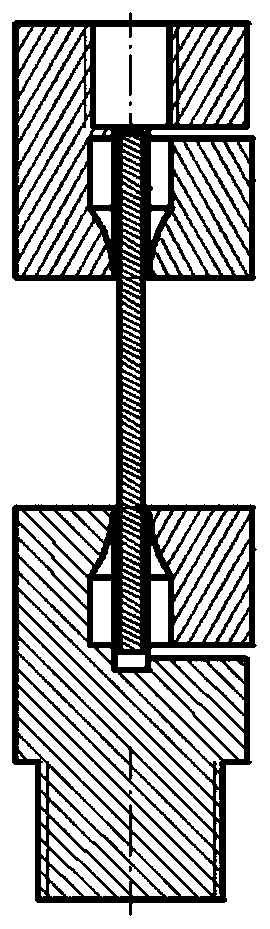

[0035] In the figure, 1 is a synchrotron radiation source, 2 is a monochromator, 3 is a top cover, 4 is a support tube, 5 is a load cell, 6 is an upper clamp, 7 is a sample, 8 is a lower clamp, and 9 is a transparent enclosure , 10 is the light source experiment platform, 11 is the X-ray detector, 12 is the hydraulic oil pipe, 13 is the electro-hydraulic servo valve, 14 hydraulic station, 15 data acquisition and controller (ie data acquisition and control unit), 16 data processing unit, 17 is the light source experiment platform, 18 is the imaging platform, 19 is the locking screw, 20 is the base of the testing machine, 21 is the displacement sensor, and 22 is the servo hydraulic cylinder.

[0036] figure 1 Shown, a large-load high-frequency in-situ tensile and fatigue testing machine based on X-ray imaging, including a data processing unit 16, a hydraulic station 14, and a light source

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap